We all have different approaches to polishing machine parts.

What we are looking for is minimum effort for maximum effect. I can't be bothered going through various grades of emery paper, or what ever.

Dings I attempt to file out, then linish or a lick with emery paper.

If the part is rusty, I attack it with a Scotchbrite rough finishing wheel mounted on a tapered mandrel in the grinder. On the other end is a fine Scotchbrite finishing wheel.

The rough wheel produces a course satin finish, and will remove metal, so don't press too hard. The finer wheel produces a nice satin finish. These processes are done dry.

Off with those wheels and on with a stitched sisal wheel one end, and a soft sisal or calico wheel the other. Using the stitched sisal wheel and some black "Fast-cut" compound will produce a nice shine that almost looks good enough.

The satisfaction comes from using the calico wheel and some Green compound. This quickly produces a bright chrome like finish. That's it, simple.

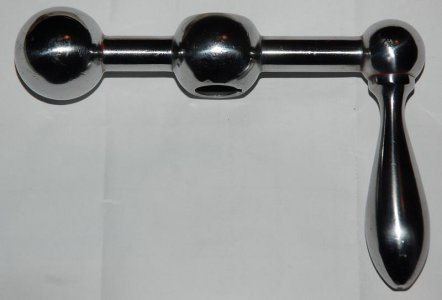

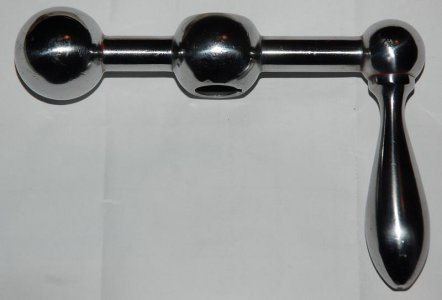

The pictures show the handle part polished with rust, the other fully polished.

Do you have any tips you would like to share?

Ken

What we are looking for is minimum effort for maximum effect. I can't be bothered going through various grades of emery paper, or what ever.

Dings I attempt to file out, then linish or a lick with emery paper.

If the part is rusty, I attack it with a Scotchbrite rough finishing wheel mounted on a tapered mandrel in the grinder. On the other end is a fine Scotchbrite finishing wheel.

The rough wheel produces a course satin finish, and will remove metal, so don't press too hard. The finer wheel produces a nice satin finish. These processes are done dry.

Off with those wheels and on with a stitched sisal wheel one end, and a soft sisal or calico wheel the other. Using the stitched sisal wheel and some black "Fast-cut" compound will produce a nice shine that almost looks good enough.

The satisfaction comes from using the calico wheel and some Green compound. This quickly produces a bright chrome like finish. That's it, simple.

The pictures show the handle part polished with rust, the other fully polished.

Do you have any tips you would like to share?

Ken

Last edited by a moderator: