It depends upon what you are trying to measure, its size, and the required accuracy. Diameters are easily measured, turned lengths, not so much. If I were necking down a piece to a shoulder (like a top hat), I would be inclined to set up a carriage stop corresponding to the top of the brim of the top hat. I would then place a spacer of the exact length of the neck between the stop and the carriage. Now the carriage will stop at the top of the neck. This is particularly useful if making multiple parts as there isn't a need for a lot of measurement checks.

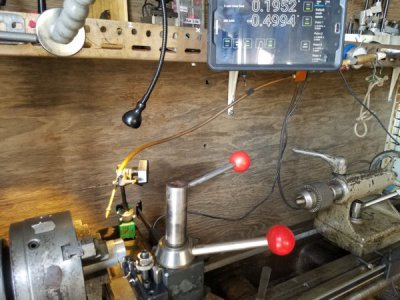

If I was facing a bar to length, I would use a spindle stop. Place thwe spindle stop in the bore of the spindle. Set the compound so its travel is parallel to the spindle axis. Make a trial oversized cut with the work tight to the stop and the carriage locked down.. Pull the work out of the lathe and measure, determine a corrective cut and adjust the compound accordingly. For more accuracy, the compound can be set at an angle of 84.3º to the spindle axis so each inch of compound travel move .1" in the direction parallel to the spindle axis.

It is also possible to face a bar to length by cutting it slightly oversized, removing and measuring, and then touching off the cutting tool on the previously cut face and adjust the tool position as required.

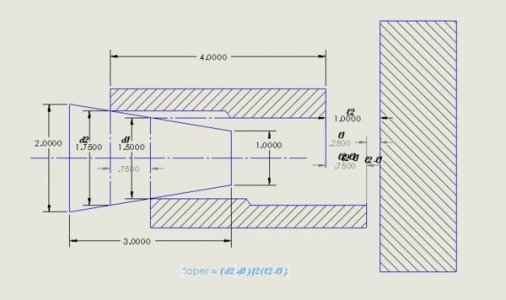

Tapers can be a real bugger to measure. The two cylinder method works. A short cylinder with appropriate slightly different internal diameters is used. A dial indicator is set up to measure the position of the tailstock e4nd of the cylinder when the cylinder is fitted to the taper. The indicator position is recorded and the cylinder is reversed and its position measured with the indicator. The difference in the diameter, coupled with the difference in the indicator readings and a little trigonometry will give you the taper. Measuring the diameter of the large end of a taper is a piece of cake, the small end, not so easy. If possible, I will turn a cylinder on the small end of the taper with a diameter equal to the small diameter of the taper. I will then cut off the cylinder at the intersection with the taper.

Internal bores can be measured with gage pins, bore gages, or telescoping gages. Internal tapers can be measured with ball bearings. Having a mating part to the taper is also useful in determining correct machining. And of course, depth gages for bore depths.