here are some pix of some tool holders i am making for my 7x12. these are for the a2z cnc tool post. last weekend i started hack sawing the 1x1 aluminum pieces, and i got my dovetail cutter on monday, and now i have 10 tool holders today! or at least have the dovetails cut in 10 pieces. i have 6 completed blocks that just need adjuster nuts, and 4 blank ones.

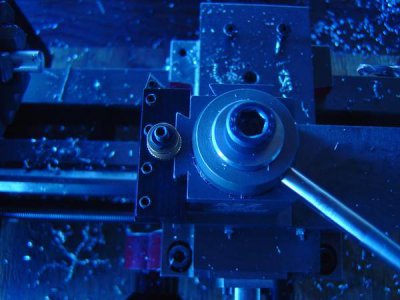

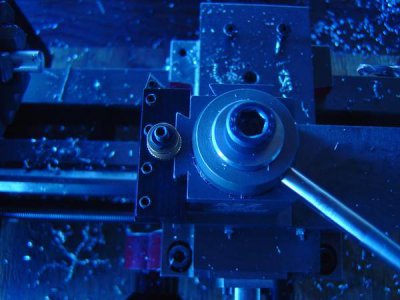

here is my modified tool post. i drilled the hub to m6 at an angle so that the handle is higher and out of the way, and made a new handle. i also made new pistons for the tool post so it locks in the 45 degree position weather i use the turning or boring dovetail, just like a real toolpost! also made a new bushing/"mounting kit" for it with a better fit. i will get pics of the tool post mods if anyone is interested.

fits just like an original.

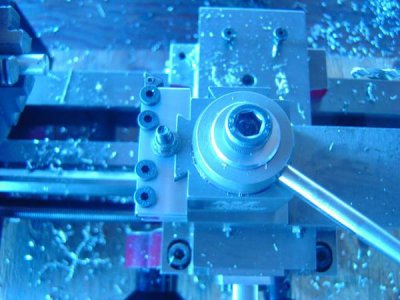

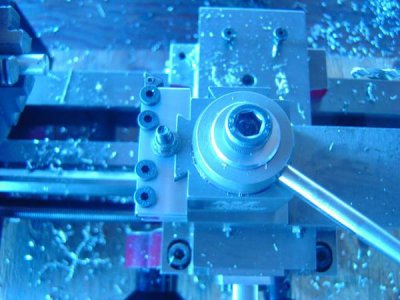

here is my modified tool post. i drilled the hub to m6 at an angle so that the handle is higher and out of the way, and made a new handle. i also made new pistons for the tool post so it locks in the 45 degree position weather i use the turning or boring dovetail, just like a real toolpost! also made a new bushing/"mounting kit" for it with a better fit. i will get pics of the tool post mods if anyone is interested.

fits just like an original.