- Joined

- Jun 20, 2016

- Messages

- 346

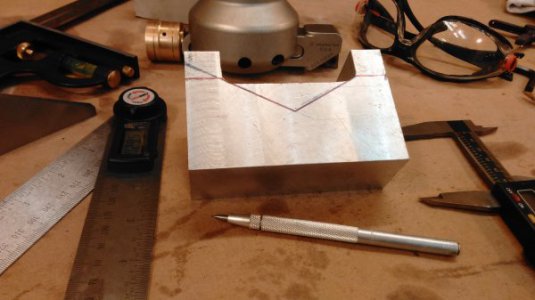

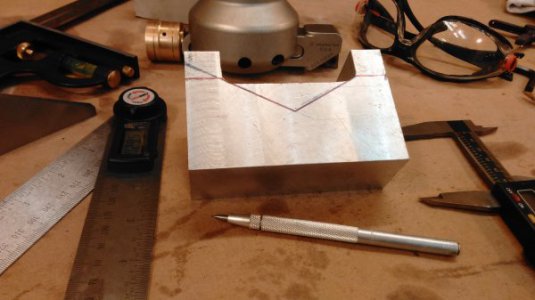

I posted this in POTD , but now I have a question before i go further and cut the angles .

What do you guys think about this ? Looking at the layout it did in red sharpie you can see I don't run the angles all the way to the end. I stop them at flats that are just under 3/4" wide ...my thought is that if I run the angles out too far, the thing would get weak if I held something large enough to contact only at the ends . Do you guys think that's reasonable or could I extend the angles out a little farther ? If I go out just a little farther i'd have 1/2" flats at the ends, and the width it could hold would be greater . This is 6061 , not steel . Anyone have any thoughts on this

What do you guys think about this ? Looking at the layout it did in red sharpie you can see I don't run the angles all the way to the end. I stop them at flats that are just under 3/4" wide ...my thought is that if I run the angles out too far, the thing would get weak if I held something large enough to contact only at the ends . Do you guys think that's reasonable or could I extend the angles out a little farther ? If I go out just a little farther i'd have 1/2" flats at the ends, and the width it could hold would be greater . This is 6061 , not steel . Anyone have any thoughts on this