- Joined

- Feb 5, 2015

- Messages

- 662

The following project may seem trivial but the configuration and tolerances can be challenging to those of us with old machinery - no DROs just the dials on the cranks and maybe a travel indicator on the lathe.)

A few years ago my fourteen-year-old nephew Kurt, who is very interested in "yo-yos", showed me a rough sketch, including dimensions and weight, of his ideal device. This isn't about old wooden "Duncans" or newer plastic devices illuminated with flashing LEDs. Kurt was envisioning a modern version made of metal, including features like a ball-bearing axis and low-friction side pads. Apparently, these are necessary for advanced tricks, and are readily available (although costly).

Kurt did some internet research and purchased parts for his prospective design. One was a ball-bearing with an outer race ground in a shallow concave arc, to guide the tether string toward the center of gravity. He also obtained a pair of low friction pads (shaped like washers, made of "Teflon" or a similar low-friction material) that fit into grooves on either side of the hub. The purpose, he tells me, is to reduce friction of the tether string against the side surfaces of the yo-yo.

We discussed considerations to increase "spin time" of the yo-yo. The yo-yo is a flywheel so we want the greatest amount of mass distributed as far away from the spin axis as possible to maximize stored rotational energy. Kurt's original concept evolved from a pair of aluminum discs to a four-piece design consisting of thin aluminum hubs attached to rims with more mass. The choice of rim materials could include most of the ferrous or copper-based alloys, since these are about three times the density of the aluminum selected for the hub material.

This is the design that we conceived (chamfer/radii of sharp corners not shown). To provide a scale factor, the yo-yo is 2.300 inches diameter x 1.625 from rim-to-rim.

There isn't much in the design that is dimensionally critical other than the ball-bearing interface, the low-friction pad grooves and the fit between the hubs and the rims. But it's important that the yo-yo be well-balanced, according to my nephew. I arbitrarily decided that non-critical tolerances should be +/- .005 inches which is not normally a difficult requirement. In this case, multiple odd angular transitions exist so accounting for backlash is more than the usual procedure of taking up the slack in a single direction.

In any situation more complicated than turning, turning to a shoulder or facing - one or several times - it's good to consider the sequence of events. It's especially important when dealing with structures that aren't orthogonal or rigid and the thin hub sections of this yo-yo project aren't very rigid (and far from orthogonal). Diameters of the various parts are too large to fit in a normal lathe collet; the workpiece needs to be held in a chuck, a pot-collet or a shop-made mandrel and it's desirable to perform as many operations as possible without flipping the part and losing concentricity, making the center of gravity unpredictable. (I'm taking all of this on faith from my nephew, mind you, since I know little about this "sport".)

"Wobble" is not good - the parts need to be concentric for maximum conservation of energy and "smoothness" of spin, right? I planned a sequence of operations that seemed sensible, progressing through the processes of turning/boring/drilling/tapping and of course, de-burring and finish improvement. The hubs are flimsy and deflect under turning or boring pressures - this requires sharp tooling.

Deflection of the outer rim of the hub was problematical because high spindle speeds caused the O.D. of the rim to centrifugally expand. For example: without moving the cutting tool location and changing the spindle RPM from 400 to 950 produced a measurable difference in the turned diameter - nearly .001. This wasn't due to a "spring" cut, just centrifugal expansion of the perimeter of the workpiece due to the flexible cross section !

This wouldn't normally be a problem but CAN be for precise work. A lesson for me was that we frequently change spindle speeds when transitioning from roughing to finish cuts - usually increasing speed for the finish cut. This could detrimentally affect accuracy in irregularly-shaped workpieces with thin cross-sections. The finished diameter of the aluminum hub was fairly critical for a shrink fit with the rim material. Keeping this in mind, had I spun up the spindle for the final cut (after roughing at a low RPM), the expansion of the O.D. would have resulted in the finish diameter being SMALLER than the design value - the part would have been out of tolerance and the rims could not have been shrunk to fit the hubs. (If the rims had already been produced, they would have been scrapped - new ones would have had to be made to accommodate the hub O.D. error.)

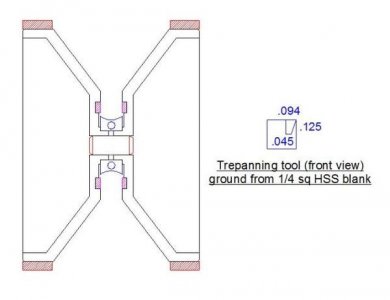

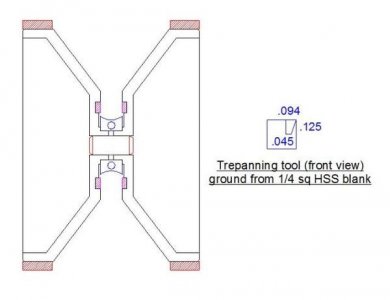

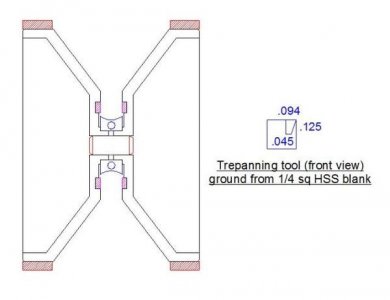

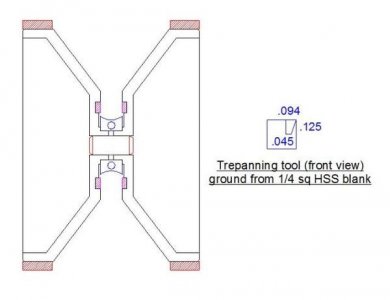

Both hubs were roughed to shape in a 3-jaw chuck except for the bearing and friction pad features which were finished to size (a 1/4 square HSS trepanning tool was ground to produce the friction pad grooves in one pass, the dimensions of which were shown in the initial sketch above). The next step was weighing the hubs to get a rough idea of the consistency of the two halves.

The lab balance in the photo, will be easily recognized by those who hand-load ammunition. The scale has the capability of resolving tenths of a "grain" up to 1000 grains. Differentiating weights down to .0000143 pounds or .00023 ounces is possible, at least in theory, up to a maximum of around 2 ounces. This was an interesting exercise: comparing the calculated weight of an object with a complex shape with the actual weight.

Rather than drilling a pilot hole for the #8-32 tapped hole in the center of the yo-yo halves, the hole was bored (with a 1/8 diameter end mill) for maximum concentricity with the other features. Finicky work but this is the type and scale of work for which I purchased my "Compact Eight" lathe some thirty years ago. Most of my work - prior to retirement - involved workpieces that fit within a fairly small envelope.

Balance and symmetry requirements suggested that the yo-yo be completed on a mandrel after the parts were semi-finished. The mandrel is in two pieces, a removable section that threads onto a fixed stub held in 3-jaw chuck (the threaded part of the mandrel accommodates the tapped holes in the yo-yo hubs). The removable part can be supported by the tailstock center for greater precision at high spindle speeds. I wanted to perform the final finishing operations with the yo-yo completely assembled so that all features would be concentric. The hubs were secured between the mandrel parts, separated by the ball bearing (used as a spacer) and steadied by the tailstock. Making the mandrel was a routine task but a few items are worth noting.

I know, I know, it's hard to take this project seriously - a YO-YO, for goodness sake ! The interests of teen-age boys (except in some areas) are unpredictable but definitely compelling.

The mandrel was made from 1018 CRS, cut to length on the ubiquitous small Chinese horizontal bandsaw. During sawing, when I need to attend to other tasks, it's not practical to apply coolant to the bandsaw blade. Cobbling up a drip-coolant for the saw has been low on the priority list so I devised this cheap trick to lubricate the blade while otherwise occupying myself. I save old candle stubs (electrical power is sometimes intermittent during the winter) and lay a stub next to the workpiece being sawed. The saw blade picks up enough candle wax to keep the blade lubed.

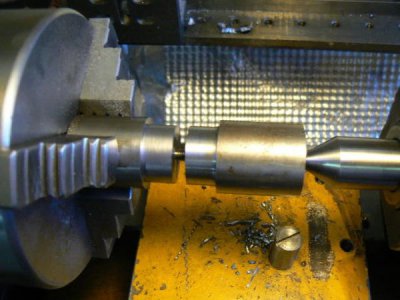

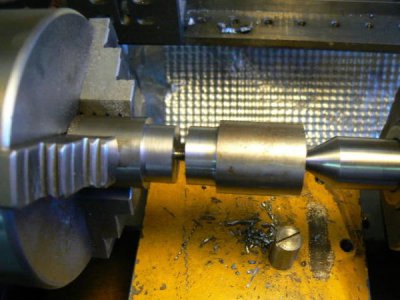

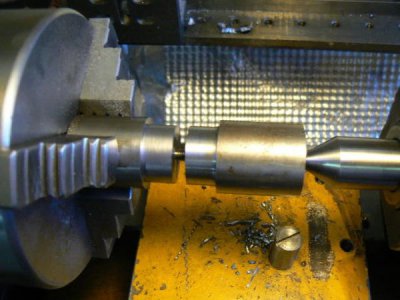

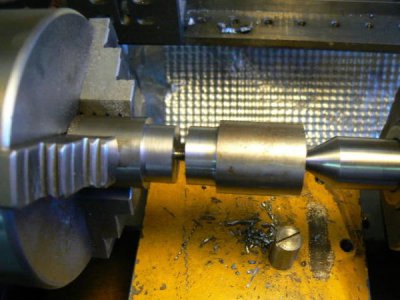

Here's a roughing pass on the fixed mandrel, .250 depth of cut, .007 IPR on my small 8 inch lathe. A sharp HSS tool combined with sulphur-based cutting oil has always provided excellent results on this material (actually, as you can see, it cuts pretty good without coolant but is harder on the tool). Had I the need to remove large amounts of steel in a hurry, I likely would have used a carbide insert but going from one inch diameter to .162 diameter only takes two passes with a sharp tool. Cutting efficiency, at least for a single workpiece, isn't normally of importance to a retired person.

The next pass produced the finish diameter, followed by a thread chasing head to produce 8-32UNC-2A threads. (Although I just implied that machining time isn't that important, I do not have the patience for single-pointing small diameter threads when I can chase them in fifteen seconds.)

The faces of both mandrel parts were undercut, so that the yo-yo hubs could be gripped at the perimeter of the mandrel, minimizing flexing during subsequent operations. One might wonder why this would be necessary but the several different facing operations and the several interfaces (between hubs, bearing races and mandrel surfaces) suggest that perpendicularity and concentricity MIGHT otherwise be a problem. Making peripheral contact - as opposed to an uncertain contact across a wide surface - is likely to produce the most satisfactory results.

This is the completed mandrel:

The hubs were mounted in the mandrel and finish-turned to final dimension. At this point many will be wondering how these thin parts turned from solid bar were not singing like a tuning fork and producing distinct chatter marks.

And of course the parts WERE singing like a tuning fork whenever the boring tool approached areas of the workpiece that stimulated the natural resonant frequency. There are techniques for minimizing chatter marks resulting from this problem. A common one is to pack internal cavities of a workpiece with putty or modeling clay - this works well for thin-section workpieces if the clay can be packed in such a manner as to prevent it being flung out.

In this case, dipping a finger in cutting oil and lightly touching the surface opposite the cutting tool was adequate to dampen the resonance and produce an acceptable finish. The next photo shows the O.D. being turned for a shrink fit with the rims while mounted on the mandrel. Obviously this would have been better performed with chip-breaker geometry, eliminating the messy, stringy pile-up caused by the sharp tool.

Looking through my small stock of materials, I didn't find anything suitable for yo-yo rims. There are no metal suppliers in this part of northern California - the best suppliers would be about four hours south, via a sometimes narrow two-lane highway winding through the mountains among the redwoods. The second choice would be three and one-half hours east, via a sometimes narrow, two lane highway winding through the mountains among the Douglas firs, LOL.

After noting the outrageous prices that hobby-oriented internet metals suppliers charge for their "treasures" (not to mention shipping costs) I e-mailed a friend nearby, who operates a one-man job shop, and described my problem. He has always been generous with parts and materials, the use of his machinery, his time and his years of knowledge/experience as a millwright (now retired). He rang my doorbell a few days later, with 25 pounds of various materials he considered dimensionally appropriate for the yo-yo project.

For density, I selected a naval bronze blank … the rims were drilled and then bored to finish I.D. dimension in a 3-jaw chuck, then sawed to length (slightly oversize). I was surprised at how "finicky" cutting this material turned out to be. I substituted different configurations of boring tools, varying spindle speed, feeding the carriage by hand until the right combination was determined, mostly by "feel".

This is a situation where large Morse taper drills are very useful. Unfortunately one requires horsepower to take full advantage of big drills - I had to feed lightly with the small, underpowered lathe I’d set up for this part, to prevent slipping the drive belts. The owners of other small lathes (South Bend, Sheldon, Atlas, Logan) may be familiar with this problem although flat belts are much better than the vee belts on my Emco. (Given the horsepower limitations it probably would have been quicker to bore the excess material from a 1/2 drilled hole using carbide and a high spindle speed.)

The bored blanks were faced to near finish width but the O.D. was left rough. The bore dimension had been previously determined for a shrink fit with the hub O.D. based on the thermal expansion characteristics of the two different materials and the desired overall dimensions.

A shrink fit is a good way to achieve a permanent joint between rotating parts (all performance parameters being considered) and for a yo-yo, not much has to be considered. Aluminum has a linear temperature expansion of about 23 ppm/degree C/inch while bronze is about 19 ppm/degree C/inch (ppm = parts per million = 1 ^ (10-6).

Desiring a simple method of shrink-fitting the parts, I put the aluminum hubs in the freezer and the rims in the oven. The aluminum hub will shrink by about 23(10-6) x 25 x 2.115 (the O.D. of the hub) or about -.0012 inches. The bronze rim will expand by about 19(10-6) x 230 x 2.115, approximately +.009 inches … so when the two parts are at their temperature extremes, the interface clearance will be about +.010. After 30 minutes temperature soak, the parts were removed, easily fitted together and then allowed to reach room temperature. The halves were rough-turned and faced to identical dimensions so that their weights could be determined.

After weighing the halves for consistency, they were reinstalled on the mandrel. The final lathe operation of the yo-yo was completed by facing the rims flush to the hubs and turning the rim OD to finish dimension. Removing the halves from the mandrel and re-weighing, the two parts were within 5 grains of one another (0.01 ounce). The O.D. of the yo-yo was intentionally left about .125 oversize so that Kurt could test drive it before further modification.

After trying out the yo-yo, Kurt liked the "feel" and the diameter of the rims but felt that removing a bit more weight would be helpful. I should mention at this point that the boy is GOOD with a yo-yo, he performs tricks that are orders of magnitude more complex than I recall from my childhood and competes at state and national level (who knew that there were yo-yo competitions ?).

We decided to lighten the hub because removing material from it wouldn't noticeably reduce spin time, the greatest mass is in the rim. At this point, the yo-yo is very difficult to fixture since the walls are thin and flex easily. I made a "collet-like" split clamping device from a slice of 4 x 4 timber, bored in the vertical mill to fit the O.D. of the yo-yo halves and split diagonally, part-way through, in the table saw. (The halves could have been held in the 4-jaw on my rotary table but this was way quicker than mounting the sixty-pound table and dialing in the parts.)

Installing the halves in the split block, clamping in the mill vise and applying some side pressure with a "C" clamp held the thin parts so that 7/16 diameter holes could be plunged through the hubs. The intention was to produce eight holes in each hub but Kurt stopped me at four holes - he wanted to try the yo-yo again before plunging the remainder of the holes.

We reassembled the device and Kurt pronounced it perfect, in terms of size, balance and most especially spin time. Here's the yo-yo prior to de-burring, polishing and coating with shellac - all to be performed by Kurt. The teflon washers and the ball bearing have been installed and this thing will spin for a l--o--n--g time !

The project was intended to accomplish the following:

• Acquaint my nephew with a few fundamentals of metal turning

• Produce a unique device - not necessarily better than a commercial product but a custom-designed, hand-crafted product that Kurt would value because of his personal contributions to the design and to the construction

• Introduce a performance advantage by composite construction: lightweight hub + heavier rims = more stored energy. This resulted in longer "spin" time, allowing the boy to perform more elaborate "tricks"

Cheers, hope you've enjoyed reading about this small project. If the design was successful, my nephew will advise me after his next competition, LOL. I expect his interest in yo-yo competition will last only until he discovers girls - any day now, LOL.

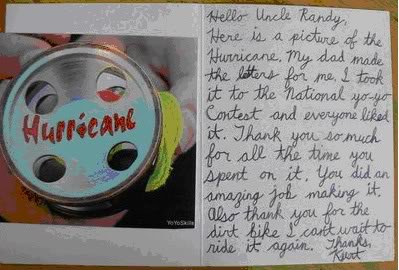

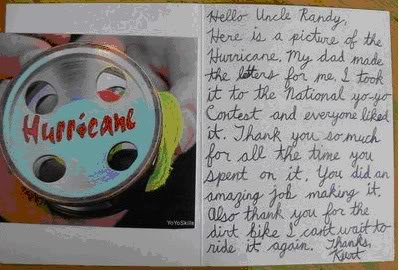

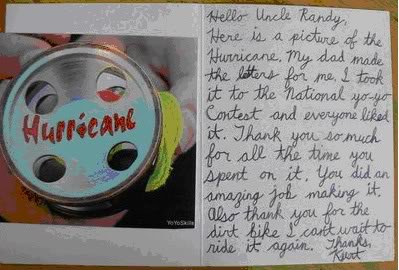

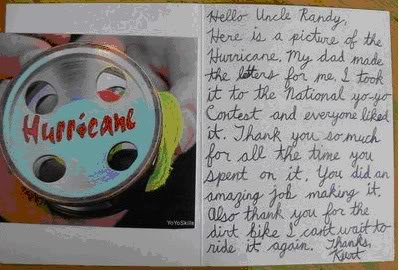

It should go without saying that the project took twice as long as I'd estimated. A few weeks later, I received the following thank-you card from Kurt. I was touched by the fact that he first wrote the message in pencil and then over-wrote in ink. He's a great kid !

Cheers,

Randy C (and my capable apprentice, Kurt)

A few years ago my fourteen-year-old nephew Kurt, who is very interested in "yo-yos", showed me a rough sketch, including dimensions and weight, of his ideal device. This isn't about old wooden "Duncans" or newer plastic devices illuminated with flashing LEDs. Kurt was envisioning a modern version made of metal, including features like a ball-bearing axis and low-friction side pads. Apparently, these are necessary for advanced tricks, and are readily available (although costly).

Kurt did some internet research and purchased parts for his prospective design. One was a ball-bearing with an outer race ground in a shallow concave arc, to guide the tether string toward the center of gravity. He also obtained a pair of low friction pads (shaped like washers, made of "Teflon" or a similar low-friction material) that fit into grooves on either side of the hub. The purpose, he tells me, is to reduce friction of the tether string against the side surfaces of the yo-yo.

We discussed considerations to increase "spin time" of the yo-yo. The yo-yo is a flywheel so we want the greatest amount of mass distributed as far away from the spin axis as possible to maximize stored rotational energy. Kurt's original concept evolved from a pair of aluminum discs to a four-piece design consisting of thin aluminum hubs attached to rims with more mass. The choice of rim materials could include most of the ferrous or copper-based alloys, since these are about three times the density of the aluminum selected for the hub material.

This is the design that we conceived (chamfer/radii of sharp corners not shown). To provide a scale factor, the yo-yo is 2.300 inches diameter x 1.625 from rim-to-rim.

There isn't much in the design that is dimensionally critical other than the ball-bearing interface, the low-friction pad grooves and the fit between the hubs and the rims. But it's important that the yo-yo be well-balanced, according to my nephew. I arbitrarily decided that non-critical tolerances should be +/- .005 inches which is not normally a difficult requirement. In this case, multiple odd angular transitions exist so accounting for backlash is more than the usual procedure of taking up the slack in a single direction.

In any situation more complicated than turning, turning to a shoulder or facing - one or several times - it's good to consider the sequence of events. It's especially important when dealing with structures that aren't orthogonal or rigid and the thin hub sections of this yo-yo project aren't very rigid (and far from orthogonal). Diameters of the various parts are too large to fit in a normal lathe collet; the workpiece needs to be held in a chuck, a pot-collet or a shop-made mandrel and it's desirable to perform as many operations as possible without flipping the part and losing concentricity, making the center of gravity unpredictable. (I'm taking all of this on faith from my nephew, mind you, since I know little about this "sport".)

"Wobble" is not good - the parts need to be concentric for maximum conservation of energy and "smoothness" of spin, right? I planned a sequence of operations that seemed sensible, progressing through the processes of turning/boring/drilling/tapping and of course, de-burring and finish improvement. The hubs are flimsy and deflect under turning or boring pressures - this requires sharp tooling.

Deflection of the outer rim of the hub was problematical because high spindle speeds caused the O.D. of the rim to centrifugally expand. For example: without moving the cutting tool location and changing the spindle RPM from 400 to 950 produced a measurable difference in the turned diameter - nearly .001. This wasn't due to a "spring" cut, just centrifugal expansion of the perimeter of the workpiece due to the flexible cross section !

This wouldn't normally be a problem but CAN be for precise work. A lesson for me was that we frequently change spindle speeds when transitioning from roughing to finish cuts - usually increasing speed for the finish cut. This could detrimentally affect accuracy in irregularly-shaped workpieces with thin cross-sections. The finished diameter of the aluminum hub was fairly critical for a shrink fit with the rim material. Keeping this in mind, had I spun up the spindle for the final cut (after roughing at a low RPM), the expansion of the O.D. would have resulted in the finish diameter being SMALLER than the design value - the part would have been out of tolerance and the rims could not have been shrunk to fit the hubs. (If the rims had already been produced, they would have been scrapped - new ones would have had to be made to accommodate the hub O.D. error.)

Both hubs were roughed to shape in a 3-jaw chuck except for the bearing and friction pad features which were finished to size (a 1/4 square HSS trepanning tool was ground to produce the friction pad grooves in one pass, the dimensions of which were shown in the initial sketch above). The next step was weighing the hubs to get a rough idea of the consistency of the two halves.

The lab balance in the photo, will be easily recognized by those who hand-load ammunition. The scale has the capability of resolving tenths of a "grain" up to 1000 grains. Differentiating weights down to .0000143 pounds or .00023 ounces is possible, at least in theory, up to a maximum of around 2 ounces. This was an interesting exercise: comparing the calculated weight of an object with a complex shape with the actual weight.

Rather than drilling a pilot hole for the #8-32 tapped hole in the center of the yo-yo halves, the hole was bored (with a 1/8 diameter end mill) for maximum concentricity with the other features. Finicky work but this is the type and scale of work for which I purchased my "Compact Eight" lathe some thirty years ago. Most of my work - prior to retirement - involved workpieces that fit within a fairly small envelope.

Balance and symmetry requirements suggested that the yo-yo be completed on a mandrel after the parts were semi-finished. The mandrel is in two pieces, a removable section that threads onto a fixed stub held in 3-jaw chuck (the threaded part of the mandrel accommodates the tapped holes in the yo-yo hubs). The removable part can be supported by the tailstock center for greater precision at high spindle speeds. I wanted to perform the final finishing operations with the yo-yo completely assembled so that all features would be concentric. The hubs were secured between the mandrel parts, separated by the ball bearing (used as a spacer) and steadied by the tailstock. Making the mandrel was a routine task but a few items are worth noting.

I know, I know, it's hard to take this project seriously - a YO-YO, for goodness sake ! The interests of teen-age boys (except in some areas) are unpredictable but definitely compelling.

The mandrel was made from 1018 CRS, cut to length on the ubiquitous small Chinese horizontal bandsaw. During sawing, when I need to attend to other tasks, it's not practical to apply coolant to the bandsaw blade. Cobbling up a drip-coolant for the saw has been low on the priority list so I devised this cheap trick to lubricate the blade while otherwise occupying myself. I save old candle stubs (electrical power is sometimes intermittent during the winter) and lay a stub next to the workpiece being sawed. The saw blade picks up enough candle wax to keep the blade lubed.

Here's a roughing pass on the fixed mandrel, .250 depth of cut, .007 IPR on my small 8 inch lathe. A sharp HSS tool combined with sulphur-based cutting oil has always provided excellent results on this material (actually, as you can see, it cuts pretty good without coolant but is harder on the tool). Had I the need to remove large amounts of steel in a hurry, I likely would have used a carbide insert but going from one inch diameter to .162 diameter only takes two passes with a sharp tool. Cutting efficiency, at least for a single workpiece, isn't normally of importance to a retired person.

The next pass produced the finish diameter, followed by a thread chasing head to produce 8-32UNC-2A threads. (Although I just implied that machining time isn't that important, I do not have the patience for single-pointing small diameter threads when I can chase them in fifteen seconds.)

The faces of both mandrel parts were undercut, so that the yo-yo hubs could be gripped at the perimeter of the mandrel, minimizing flexing during subsequent operations. One might wonder why this would be necessary but the several different facing operations and the several interfaces (between hubs, bearing races and mandrel surfaces) suggest that perpendicularity and concentricity MIGHT otherwise be a problem. Making peripheral contact - as opposed to an uncertain contact across a wide surface - is likely to produce the most satisfactory results.

This is the completed mandrel:

The hubs were mounted in the mandrel and finish-turned to final dimension. At this point many will be wondering how these thin parts turned from solid bar were not singing like a tuning fork and producing distinct chatter marks.

And of course the parts WERE singing like a tuning fork whenever the boring tool approached areas of the workpiece that stimulated the natural resonant frequency. There are techniques for minimizing chatter marks resulting from this problem. A common one is to pack internal cavities of a workpiece with putty or modeling clay - this works well for thin-section workpieces if the clay can be packed in such a manner as to prevent it being flung out.

In this case, dipping a finger in cutting oil and lightly touching the surface opposite the cutting tool was adequate to dampen the resonance and produce an acceptable finish. The next photo shows the O.D. being turned for a shrink fit with the rims while mounted on the mandrel. Obviously this would have been better performed with chip-breaker geometry, eliminating the messy, stringy pile-up caused by the sharp tool.

Looking through my small stock of materials, I didn't find anything suitable for yo-yo rims. There are no metal suppliers in this part of northern California - the best suppliers would be about four hours south, via a sometimes narrow two-lane highway winding through the mountains among the redwoods. The second choice would be three and one-half hours east, via a sometimes narrow, two lane highway winding through the mountains among the Douglas firs, LOL.

After noting the outrageous prices that hobby-oriented internet metals suppliers charge for their "treasures" (not to mention shipping costs) I e-mailed a friend nearby, who operates a one-man job shop, and described my problem. He has always been generous with parts and materials, the use of his machinery, his time and his years of knowledge/experience as a millwright (now retired). He rang my doorbell a few days later, with 25 pounds of various materials he considered dimensionally appropriate for the yo-yo project.

For density, I selected a naval bronze blank … the rims were drilled and then bored to finish I.D. dimension in a 3-jaw chuck, then sawed to length (slightly oversize). I was surprised at how "finicky" cutting this material turned out to be. I substituted different configurations of boring tools, varying spindle speed, feeding the carriage by hand until the right combination was determined, mostly by "feel".

This is a situation where large Morse taper drills are very useful. Unfortunately one requires horsepower to take full advantage of big drills - I had to feed lightly with the small, underpowered lathe I’d set up for this part, to prevent slipping the drive belts. The owners of other small lathes (South Bend, Sheldon, Atlas, Logan) may be familiar with this problem although flat belts are much better than the vee belts on my Emco. (Given the horsepower limitations it probably would have been quicker to bore the excess material from a 1/2 drilled hole using carbide and a high spindle speed.)

The bored blanks were faced to near finish width but the O.D. was left rough. The bore dimension had been previously determined for a shrink fit with the hub O.D. based on the thermal expansion characteristics of the two different materials and the desired overall dimensions.

A shrink fit is a good way to achieve a permanent joint between rotating parts (all performance parameters being considered) and for a yo-yo, not much has to be considered. Aluminum has a linear temperature expansion of about 23 ppm/degree C/inch while bronze is about 19 ppm/degree C/inch (ppm = parts per million = 1 ^ (10-6).

Desiring a simple method of shrink-fitting the parts, I put the aluminum hubs in the freezer and the rims in the oven. The aluminum hub will shrink by about 23(10-6) x 25 x 2.115 (the O.D. of the hub) or about -.0012 inches. The bronze rim will expand by about 19(10-6) x 230 x 2.115, approximately +.009 inches … so when the two parts are at their temperature extremes, the interface clearance will be about +.010. After 30 minutes temperature soak, the parts were removed, easily fitted together and then allowed to reach room temperature. The halves were rough-turned and faced to identical dimensions so that their weights could be determined.

After weighing the halves for consistency, they were reinstalled on the mandrel. The final lathe operation of the yo-yo was completed by facing the rims flush to the hubs and turning the rim OD to finish dimension. Removing the halves from the mandrel and re-weighing, the two parts were within 5 grains of one another (0.01 ounce). The O.D. of the yo-yo was intentionally left about .125 oversize so that Kurt could test drive it before further modification.

After trying out the yo-yo, Kurt liked the "feel" and the diameter of the rims but felt that removing a bit more weight would be helpful. I should mention at this point that the boy is GOOD with a yo-yo, he performs tricks that are orders of magnitude more complex than I recall from my childhood and competes at state and national level (who knew that there were yo-yo competitions ?).

We decided to lighten the hub because removing material from it wouldn't noticeably reduce spin time, the greatest mass is in the rim. At this point, the yo-yo is very difficult to fixture since the walls are thin and flex easily. I made a "collet-like" split clamping device from a slice of 4 x 4 timber, bored in the vertical mill to fit the O.D. of the yo-yo halves and split diagonally, part-way through, in the table saw. (The halves could have been held in the 4-jaw on my rotary table but this was way quicker than mounting the sixty-pound table and dialing in the parts.)

Installing the halves in the split block, clamping in the mill vise and applying some side pressure with a "C" clamp held the thin parts so that 7/16 diameter holes could be plunged through the hubs. The intention was to produce eight holes in each hub but Kurt stopped me at four holes - he wanted to try the yo-yo again before plunging the remainder of the holes.

We reassembled the device and Kurt pronounced it perfect, in terms of size, balance and most especially spin time. Here's the yo-yo prior to de-burring, polishing and coating with shellac - all to be performed by Kurt. The teflon washers and the ball bearing have been installed and this thing will spin for a l--o--n--g time !

The project was intended to accomplish the following:

• Acquaint my nephew with a few fundamentals of metal turning

• Produce a unique device - not necessarily better than a commercial product but a custom-designed, hand-crafted product that Kurt would value because of his personal contributions to the design and to the construction

• Introduce a performance advantage by composite construction: lightweight hub + heavier rims = more stored energy. This resulted in longer "spin" time, allowing the boy to perform more elaborate "tricks"

Cheers, hope you've enjoyed reading about this small project. If the design was successful, my nephew will advise me after his next competition, LOL. I expect his interest in yo-yo competition will last only until he discovers girls - any day now, LOL.

It should go without saying that the project took twice as long as I'd estimated. A few weeks later, I received the following thank-you card from Kurt. I was touched by the fact that he first wrote the message in pencil and then over-wrote in ink. He's a great kid !

Cheers,

Randy C (and my capable apprentice, Kurt)