- Joined

- Dec 3, 2013

- Messages

- 1,844

This is not meant to bash any particular product or method of doing something just some thoughts I have about the subject.

I have seen a number of posts lately where people are replacing the stock rubber way wipers with felt. Many times the retainer is made from plastic or aluminum and not held tight to the way surface.

I recall in one post where someone said they did it because they didn't like the way that the rubber would squeegee the oil off the ways.

On my PM-1440GT it has what I consider very nice rubber wipers. They do an excellent job of exactly what they are supposed to (in my opinion) keep the oil where it is supposed to be (under the sliding surfaces) and keeps debris and grit out.

I prefer to have the exposed way dry(ish) to let particls slide off vs. sticking to the way.

The only lathes I am personally familiar with that have felt wipers are:

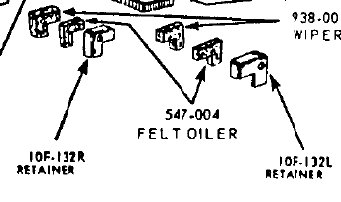

A South Bend that has felt wiper with brass retainers which are tight to the ways and fully encase the felt.

A Monarch 10ee that has felt wipers and cast iron retainers which are tight to the ways and fully encase the felt.

And a South Korean lathe made by Hwacheon (sp) that has a hybrid felt and rubber sandwich wiper with a sheet metal retainer that is also tight to the ways.

I'm assuming older machines used felt because modern rubbers were not available. Using a retainer that enveloped the felt and is tight to the way keeps most debris out of the felt and better compressed against the way creating a seal.

I'm not aware of any modern machine that uses felt wipers. Are there?

As far as I know all of the machines I listed have hardened ways. Not all hobby size lathes have hardened ways so it seems to me you would not want a wiper that has the potential to collect grit and turn your wiper into an abrasive pad. Even with hardened ways I'm careful to keep the lip of the rubber wiper clean.

I use water based flood coolant on my lathe and a felt wiper seems like a bad idea. Coolant has a way of getting everywhere and I would not want it festering in the felt of a wiper. I suspect an oil based coolant might be fine however I have no experience with them (that I can remember)

I also cut a lot of hot rolled so having a retainer that was not tight to the way would allow some of that fine scale to get collected in the felt wiper.

I will having a wiper is better than no wiper at all but if I were to use felt I would want it fully enclosed with the retainers tight to the way.

What say you?

I have seen a number of posts lately where people are replacing the stock rubber way wipers with felt. Many times the retainer is made from plastic or aluminum and not held tight to the way surface.

I recall in one post where someone said they did it because they didn't like the way that the rubber would squeegee the oil off the ways.

On my PM-1440GT it has what I consider very nice rubber wipers. They do an excellent job of exactly what they are supposed to (in my opinion) keep the oil where it is supposed to be (under the sliding surfaces) and keeps debris and grit out.

I prefer to have the exposed way dry(ish) to let particls slide off vs. sticking to the way.

The only lathes I am personally familiar with that have felt wipers are:

A South Bend that has felt wiper with brass retainers which are tight to the ways and fully encase the felt.

A Monarch 10ee that has felt wipers and cast iron retainers which are tight to the ways and fully encase the felt.

And a South Korean lathe made by Hwacheon (sp) that has a hybrid felt and rubber sandwich wiper with a sheet metal retainer that is also tight to the ways.

I'm assuming older machines used felt because modern rubbers were not available. Using a retainer that enveloped the felt and is tight to the way keeps most debris out of the felt and better compressed against the way creating a seal.

I'm not aware of any modern machine that uses felt wipers. Are there?

As far as I know all of the machines I listed have hardened ways. Not all hobby size lathes have hardened ways so it seems to me you would not want a wiper that has the potential to collect grit and turn your wiper into an abrasive pad. Even with hardened ways I'm careful to keep the lip of the rubber wiper clean.

I use water based flood coolant on my lathe and a felt wiper seems like a bad idea. Coolant has a way of getting everywhere and I would not want it festering in the felt of a wiper. I suspect an oil based coolant might be fine however I have no experience with them (that I can remember)

I also cut a lot of hot rolled so having a retainer that was not tight to the way would allow some of that fine scale to get collected in the felt wiper.

I will having a wiper is better than no wiper at all but if I were to use felt I would want it fully enclosed with the retainers tight to the way.

What say you?