Hi forum,

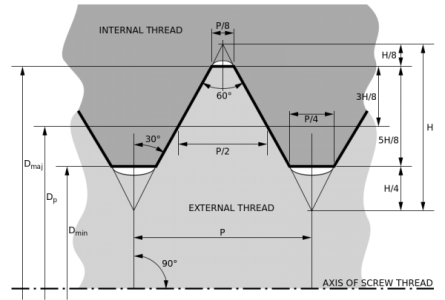

I'm new here and have a question regarding threading on the lathe. My lathe supports both imperial and metric threads, but I only use metric 60° threads.

So the job in the hobby shop today is making internal and external metric threads with "tight" fit from EN AW 2011 aluminium. The thread size is non-standard, M19x1.0. I looked at M20x1.0 and M18x1.0 and took data from those.

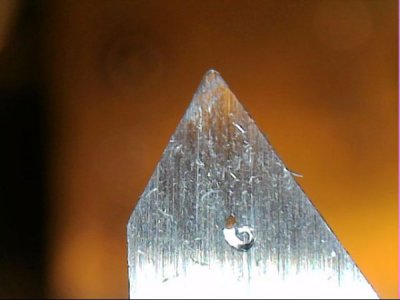

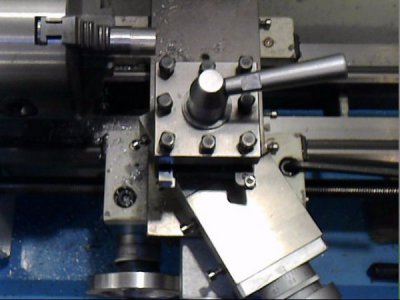

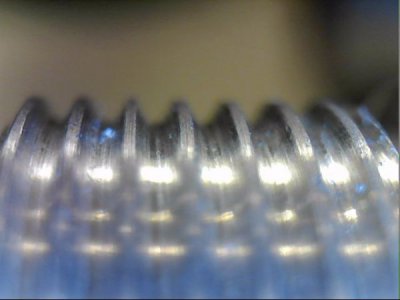

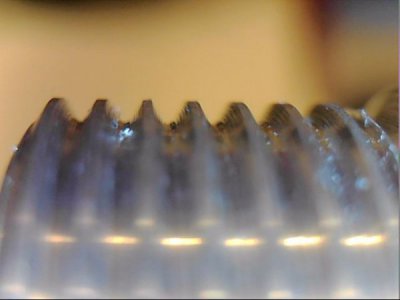

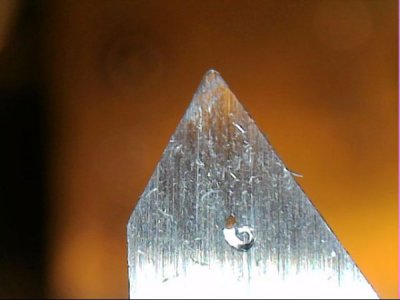

So I started with the external thread. Machined a piece down to 18.9mm, set up the 60° slide and calculated that I needed to move the slide 0.5775mm to get a thread depth of 0.5mm. The result is threads that does not look right at all, see the pictures (3 taken with a USB microscope). I think the flat top of the thread is way too wide.

I can find all these numbers online on metric threads, but not much information on how to use them for actually making the thread. The big unknown for me, is how deep do I need to cut the thread? There must be a "guideline" value that takes the 75% thread engagement into account, and then a maximum and minimum value depending on how much thread engagement you want.

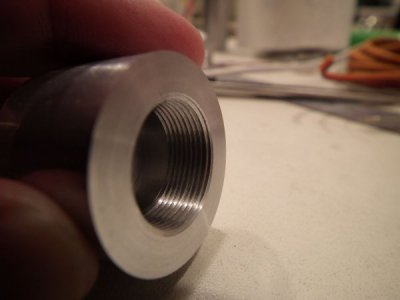

By several trial and error, I found that I could make the external thread from 18.9mm stock and thread 0.55mm into the surface. The internal thread starts with a 18.1mm hole and using 0.51mm thread depth.

I'm new here and have a question regarding threading on the lathe. My lathe supports both imperial and metric threads, but I only use metric 60° threads.

So the job in the hobby shop today is making internal and external metric threads with "tight" fit from EN AW 2011 aluminium. The thread size is non-standard, M19x1.0. I looked at M20x1.0 and M18x1.0 and took data from those.

So I started with the external thread. Machined a piece down to 18.9mm, set up the 60° slide and calculated that I needed to move the slide 0.5775mm to get a thread depth of 0.5mm. The result is threads that does not look right at all, see the pictures (3 taken with a USB microscope). I think the flat top of the thread is way too wide.

I can find all these numbers online on metric threads, but not much information on how to use them for actually making the thread. The big unknown for me, is how deep do I need to cut the thread? There must be a "guideline" value that takes the 75% thread engagement into account, and then a maximum and minimum value depending on how much thread engagement you want.

By several trial and error, I found that I could make the external thread from 18.9mm stock and thread 0.55mm into the surface. The internal thread starts with a 18.1mm hole and using 0.51mm thread depth.