- Joined

- Feb 4, 2014

- Messages

- 185

Hello Gentlemen!

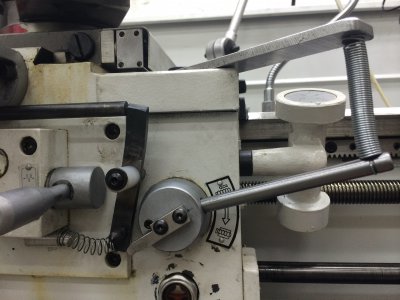

I've got a project coming up soon that is going to require a few hundred internal threads done that are fairly long. I'm not the biggest fan of rushing to disengage the halfnut milliseconds before it goes crashing into a shoulder at high speeds. And this is even worse with internal threads as and lathe owner knows. So here is my solution! A simple automated carriage stop.

[video=youtube;-Riiep0c64o]https://www.youtube.com/watch?v=-Riiep0c64o[/video]

If there is any interest I can post a full write up on the "build". It's essentially just a simply trigger, Luckily I know my guns! )

)

Anywho...Enjoy!

I've got a project coming up soon that is going to require a few hundred internal threads done that are fairly long. I'm not the biggest fan of rushing to disengage the halfnut milliseconds before it goes crashing into a shoulder at high speeds. And this is even worse with internal threads as and lathe owner knows. So here is my solution! A simple automated carriage stop.

[video=youtube;-Riiep0c64o]https://www.youtube.com/watch?v=-Riiep0c64o[/video]

If there is any interest I can post a full write up on the "build". It's essentially just a simply trigger, Luckily I know my guns!

Anywho...Enjoy!