- Joined

- Jan 15, 2013

- Messages

- 171

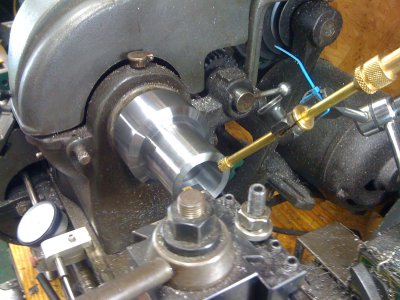

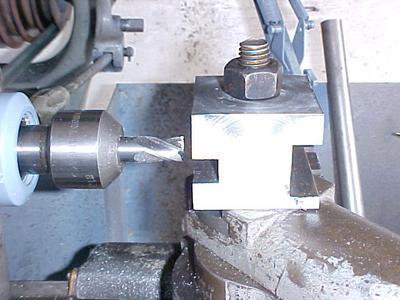

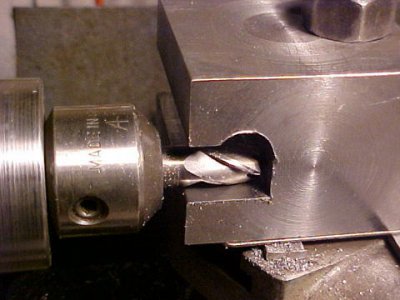

I was looking at this site http://www.deansphotographica.com/machining/atlas/ER25/ER25.html where he put a ER collet head on his lathe, I'm planning on doing similiar to my 12 x 36 craftsman with the ER40 collets.I have 3 of the nuts coming, The ER40 goes to 1" and that is about what the bore on the spindle is. Has anyone done similiar with their lathe and is this description a good method to get the angles right for the collets. It looks like i can get all the collets that i want and not have anymore then about 100.00 involved. It looks to me like it is the best way to get quick acurate sets on shaft work. My son also said that one of the advantages to the collets is that they will not leave any clamping marks on the pieces.

As one of my ways of funding mys shop i do metal casting, I have had a number of request for different size hand wheels. I pour the hand wheels with a ZA27 alloy and that part is easy but getting little hand crank to put on them has been an issue for me because of the hastle of multiple setting of the shafting and the collets would really speed that up.

Art B

As one of my ways of funding mys shop i do metal casting, I have had a number of request for different size hand wheels. I pour the hand wheels with a ZA27 alloy and that part is easy but getting little hand crank to put on them has been an issue for me because of the hastle of multiple setting of the shafting and the collets would really speed that up.

Art B