- Joined

- Nov 7, 2018

- Messages

- 186

This has been on my want list for some time, in fact it keeps me up some nights with different ideas.

As I get older it seems more often these days the tooling, chucks, face plates, vices etc. get harder for me to pick up and move around. Well I don't plan on slowing down any time soon so I have been thinking a robust rolling cart that will fit my needs. I won't bore you all with overall dimensions but the finished height will be suited for my stature and will also accommodate the mill table for those vise swaps, and future 8" rotary table. I got the idea from the iron worker support cart I built last year. That set up has worked fantastic and I don't find myself putting off tool swaps any longer.

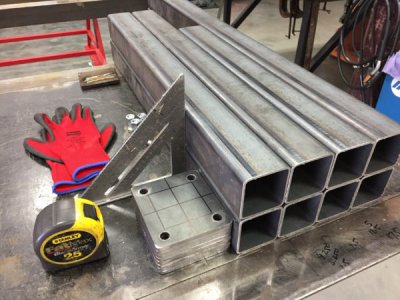

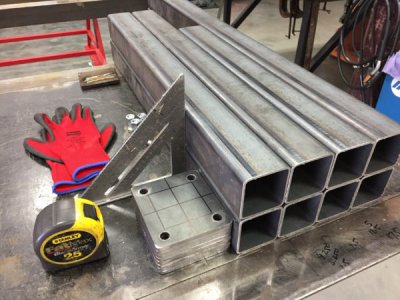

The main frame and uprights are 1/8" x 2.5" x 2.5" square. The caster plates are 1/4"x 4" flat strap sheared to 4.5" and punched. I decided to make four extra plates since I had the iron worker set up.

The punch station made short work of the 7/16" holes. The stop indexes the corners of said plates to the correct hole location. After punching, you flip the plate for second hole, rotate the plate and repeat x 2.

The same machine sheared the 4" flat bar to 4.5".

The main frame components ready for layout. The caster plates also laid out.

The casters are 5" and should roll the loaded cart with minimal effort.

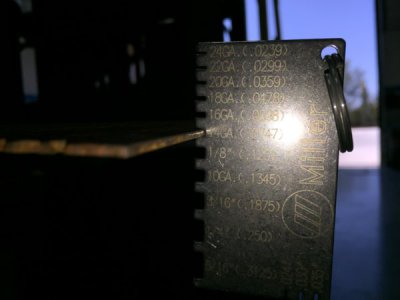

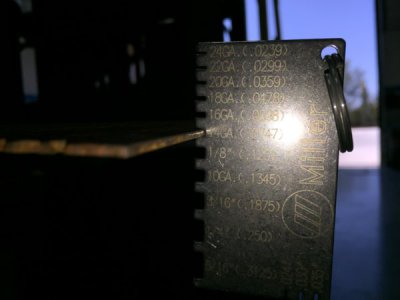

I decided to use the new Miller 252 for this entire project. Its a little different as I have grown accustomed to the push mig.

Got the main frame tacked and 1/4" x 1.5" angle iron was used for the lower shelf. This shelf will be used for the chucks, steady rear, follow rest and other heavy tooling that is seldom used.

Welded up and squared (diagonal) to exact tolerances. Controlled welding technique was used to pull legs to desired measurements. In the end, the frame is perfectly squared.

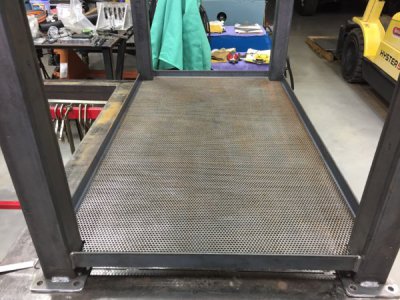

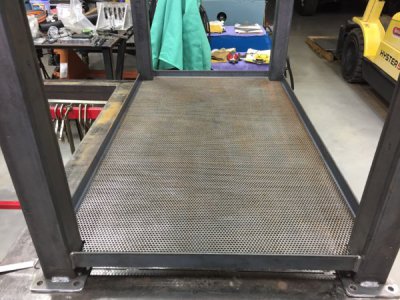

The lower shelf requires bracing to support the 14 gauge perforated sheet. I didn't want to use expanded metal since I wanted to have the ability to slide heavy tooling. The perf was leftover from years ago and has some surface rust that should clean up easily.

The plasma cutter made quick work cutting it down to size. The corner notches where made with a simple 5" grinder and cutoff wheel.

Since I had the plasma set up, I decided to cut the 1/4" top sheet. Those measurement are 30" x 48" and will have a 2" overhang on four sides of the frame.

I'm a big fan of radius edges and rounded corners so the same 5" grinder was used with a 60 grit flap disc.

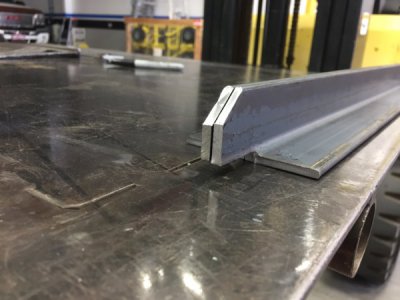

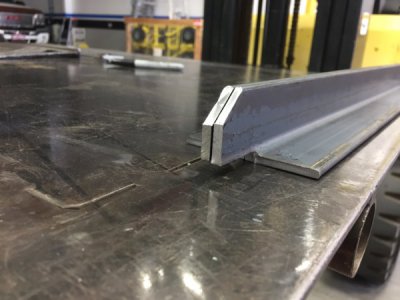

Back to the lower shelf bracing. The same angle iron was used for this and was notched on the iron worker to allow a flush fit.

A second notch the same thickness (1/4") was made to allow the leg to continue past the inside frame dimension.

A 45• notch was made to soften the corner leg on both ends.

And finally the finished soft corners.

This shows the fitment of the cross bracing from the underside of the shelf. It's clear the second notch (1/4") is required for the top of the shelf to end up flush.

The top where the perf will be welded. I still need three braces down the center using the same notching technique to prevent the 14 gauge perf from oil canning.

The perf fit nicely the first time . I used a 9" grinder with a corse cupped wire wheel to clean up the surface rust.

. I used a 9" grinder with a corse cupped wire wheel to clean up the surface rust.

A corner weld joint shot. Notice the weld seams on the tubing all face the same direction. This practice always pays off in the end once painted. All projects that have seams are never ignored.

Overall the new machine runs well.

I'm planning on a 5C collet drawer and a top rack for 3MT tooling, QCTH and other stuff. Any ideas would be appreciated......More to come later.

Thanks for looking and as always, any feed back is welcomed.

Turn and Burn!

Paco

As I get older it seems more often these days the tooling, chucks, face plates, vices etc. get harder for me to pick up and move around. Well I don't plan on slowing down any time soon so I have been thinking a robust rolling cart that will fit my needs. I won't bore you all with overall dimensions but the finished height will be suited for my stature and will also accommodate the mill table for those vise swaps, and future 8" rotary table. I got the idea from the iron worker support cart I built last year. That set up has worked fantastic and I don't find myself putting off tool swaps any longer.

The main frame and uprights are 1/8" x 2.5" x 2.5" square. The caster plates are 1/4"x 4" flat strap sheared to 4.5" and punched. I decided to make four extra plates since I had the iron worker set up.

The punch station made short work of the 7/16" holes. The stop indexes the corners of said plates to the correct hole location. After punching, you flip the plate for second hole, rotate the plate and repeat x 2.

The same machine sheared the 4" flat bar to 4.5".

The main frame components ready for layout. The caster plates also laid out.

The casters are 5" and should roll the loaded cart with minimal effort.

I decided to use the new Miller 252 for this entire project. Its a little different as I have grown accustomed to the push mig.

Got the main frame tacked and 1/4" x 1.5" angle iron was used for the lower shelf. This shelf will be used for the chucks, steady rear, follow rest and other heavy tooling that is seldom used.

Welded up and squared (diagonal) to exact tolerances. Controlled welding technique was used to pull legs to desired measurements. In the end, the frame is perfectly squared.

The lower shelf requires bracing to support the 14 gauge perforated sheet. I didn't want to use expanded metal since I wanted to have the ability to slide heavy tooling. The perf was leftover from years ago and has some surface rust that should clean up easily.

The plasma cutter made quick work cutting it down to size. The corner notches where made with a simple 5" grinder and cutoff wheel.

Since I had the plasma set up, I decided to cut the 1/4" top sheet. Those measurement are 30" x 48" and will have a 2" overhang on four sides of the frame.

I'm a big fan of radius edges and rounded corners so the same 5" grinder was used with a 60 grit flap disc.

Back to the lower shelf bracing. The same angle iron was used for this and was notched on the iron worker to allow a flush fit.

A second notch the same thickness (1/4") was made to allow the leg to continue past the inside frame dimension.

A 45• notch was made to soften the corner leg on both ends.

And finally the finished soft corners.

This shows the fitment of the cross bracing from the underside of the shelf. It's clear the second notch (1/4") is required for the top of the shelf to end up flush.

The top where the perf will be welded. I still need three braces down the center using the same notching technique to prevent the 14 gauge perf from oil canning.

The perf fit nicely the first time

A corner weld joint shot. Notice the weld seams on the tubing all face the same direction. This practice always pays off in the end once painted. All projects that have seams are never ignored.

Overall the new machine runs well.

I'm planning on a 5C collet drawer and a top rack for 3MT tooling, QCTH and other stuff. Any ideas would be appreciated......More to come later.

Thanks for looking and as always, any feed back is welcomed.

Turn and Burn!

Paco

Last edited by a moderator:

.

.