- Joined

- Feb 1, 2015

- Messages

- 9,948

I have used a part stop in my old Craftsman lathe headstock for many years. When making multiple parts, it provided accurate positioning of the parts in the chuck and it allowed removal of parts for measurement when machining to precise lengths.

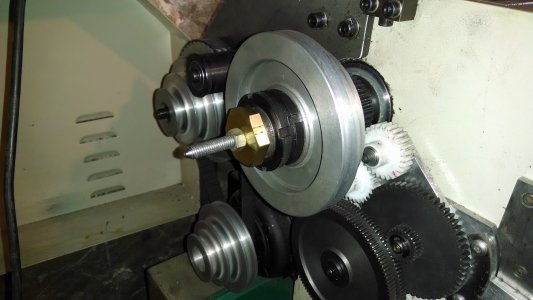

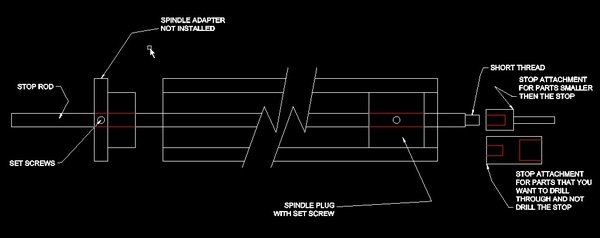

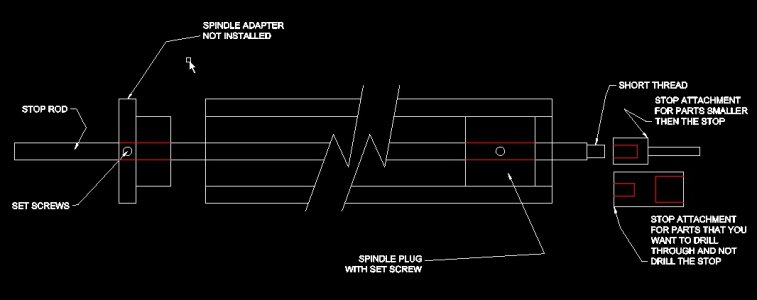

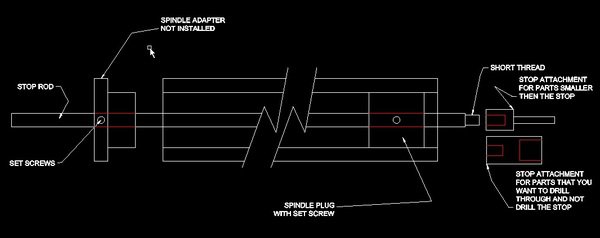

When I bought my Grizzly G0602, I really missed that feature and decided to add it . The modification is fairly simple. It consists of a 3/8 -16 x 18" threaded rod, some jam nuts, and a threaded adapter for the back end of the spindle to allow for adjustment of the rod.

A 1-1/8-16 NS tap was purchased on eBay and used to tap the spindle. As the tap was started, the spindle was rotated to verify that the tap was running true.

The adapter was made from a piece of 1-1/2" hexagonal brass bar stock. The stock was turned and threaded for a 1-1/8-16 NS thread. A scrap piece of stock was threaded with the tap and used as a thread gage. The adapter was bored and threaded for a 3/8-16 NC thread and a 75 degree countersink was cut in the base to aid in starting the threaded rod.

I made a number of threaded rods with different diameter ends to work with smaller stock. To keep the rod centered for cases where the rod end is not inside the chuck jaws, I machined a washer held in place with two nuts which centers the rod in the spindle bore. The nut end of the rods are tapered to ease in installation.

Photos show the adapter and several threaded rods made for various work. While this adapter was made for a Grizzly G0602, it can be modified to work with any lathe.

When I bought my Grizzly G0602, I really missed that feature and decided to add it . The modification is fairly simple. It consists of a 3/8 -16 x 18" threaded rod, some jam nuts, and a threaded adapter for the back end of the spindle to allow for adjustment of the rod.

A 1-1/8-16 NS tap was purchased on eBay and used to tap the spindle. As the tap was started, the spindle was rotated to verify that the tap was running true.

The adapter was made from a piece of 1-1/2" hexagonal brass bar stock. The stock was turned and threaded for a 1-1/8-16 NS thread. A scrap piece of stock was threaded with the tap and used as a thread gage. The adapter was bored and threaded for a 3/8-16 NC thread and a 75 degree countersink was cut in the base to aid in starting the threaded rod.

I made a number of threaded rods with different diameter ends to work with smaller stock. To keep the rod centered for cases where the rod end is not inside the chuck jaws, I machined a washer held in place with two nuts which centers the rod in the spindle bore. The nut end of the rods are tapered to ease in installation.

Photos show the adapter and several threaded rods made for various work. While this adapter was made for a Grizzly G0602, it can be modified to work with any lathe.