I use carbide inserts about 95% of the time and with extreme rough or interrupted cuts, the last 5%, I use bonded carbide tool bits. The inserts I use range from about $1 each to about $25 each, their type is based on the material and type of cut. I buy the bonded carbide tool bits, by the box, usually at about $.25-$.50 each, which to me, makes them throw aways. I use them to get down to the point, where I can switch to insert tools, without ruining inserts.

I started out using HSS in my grandfather's shop and continued to use them, when I got machines of my own, I got angry, when in the middle of a cut, I had to regrind the tool, and having to reset to get the tool back to the original cutting position, inserts are much easier. I think the last time I rummaged through the HSS selection, was about 8-10 years ago, when I needed a piece of 1/4 in HSS stock, for one of the friends. I haven't used HSS in the last 15+ years.

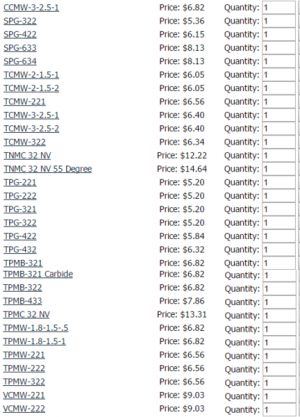

The types and grades of carbide inserts available today, is unbelievable, compared to what was available 30-40 years ago. Inserts like the CCMT series, has changed the machining world, for about 15-20 of the local (home shop) maching guys I deal with on a regular basis.