- Joined

- Mar 25, 2013

- Messages

- 5,142

I have a poor quality pinch type knurling tool that so far has not done well. I believe the machine that cut the arms was out of tram and the arms are crooked. After looking at prices I decided to make my own.

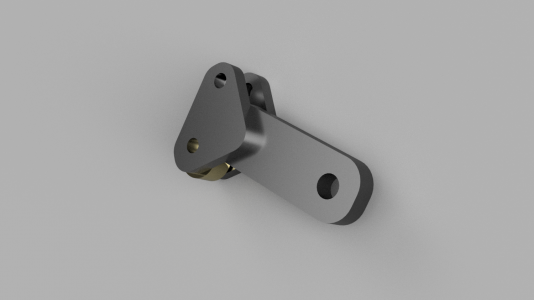

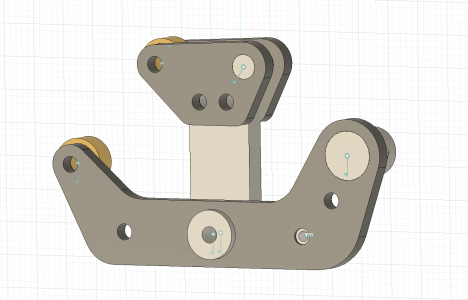

I am thinking about something like this:

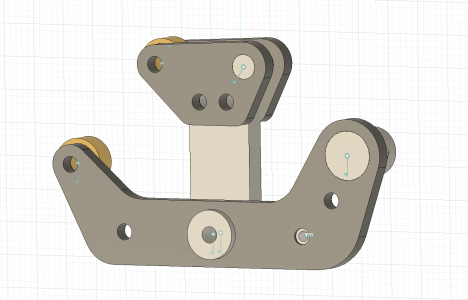

To get started I bought these:

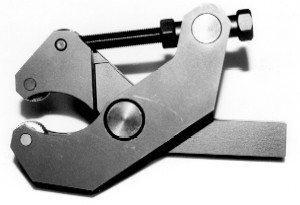

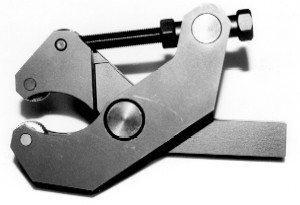

My plan is to make this tool kind of like a Kant Twist clamp. I will have a 3/8" thick piece on the inside and 1/4" arms on each side of that.

So I have an issue I need guidance with. My original plan to hold the knurling wheel was to braze or weld flat pieces on the sides of the 3/8" arm and then cross drill these. (The knurls are 3/8" wide.) Welding is not a great option due to inevitable warp and the fact that the inside of the slot is inaccessible. I tried a test piece with silver solder but I could easily make the joint fail with a wrench. Would brazing be stronger? If so, what rod and flux for mild steel? I have bronze rod and nickel silver. How can I get the braze material to flow into a joint between flats? Should I "tin" each piece first and then joint them?

Robert

EDIT for completion:

I will add the prints to this first post to make them easy to find. These may get revised over time. The prints for the 1/4" CRS parts are 1:1 so you should be able to print these on paper to duplicate the cuts.

(Rev 3/26/20)

Robert

I am thinking about something like this:

To get started I bought these:

My plan is to make this tool kind of like a Kant Twist clamp. I will have a 3/8" thick piece on the inside and 1/4" arms on each side of that.

So I have an issue I need guidance with. My original plan to hold the knurling wheel was to braze or weld flat pieces on the sides of the 3/8" arm and then cross drill these. (The knurls are 3/8" wide.) Welding is not a great option due to inevitable warp and the fact that the inside of the slot is inaccessible. I tried a test piece with silver solder but I could easily make the joint fail with a wrench. Would brazing be stronger? If so, what rod and flux for mild steel? I have bronze rod and nickel silver. How can I get the braze material to flow into a joint between flats? Should I "tin" each piece first and then joint them?

Robert

EDIT for completion:

I will add the prints to this first post to make them easy to find. These may get revised over time. The prints for the 1/4" CRS parts are 1:1 so you should be able to print these on paper to duplicate the cuts.

(Rev 3/26/20)

Robert

Attachments

-

Knurling tool assembly Drawing v1.pdf183.4 KB · Views: 45

-

Knurling tool assembly Drawing-Threaded pivot v1.pdf187.5 KB · Views: 38

-

Knurling tool assembly Drawing-Upper pivot v1.pdf169.9 KB · Views: 34

-

Knurling tool assembly Drawing- Spacers v2.pdf173.8 KB · Views: 30

-

Knurling tool assembly Drawing-Main bushing v3.pdf176.5 KB · Views: 30

-

Knurling tool assembly Drawing-upper arm v4.pdf175.3 KB · Views: 31

-

Knurling tool assembly Drawing-arm and wing v5.pdf177.2 KB · Views: 27

Last edited:

I like the Kant Twist clamp style also , lot easier to make .

I like the Kant Twist clamp style also , lot easier to make .