darkzero,

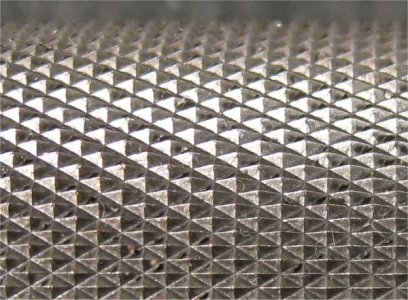

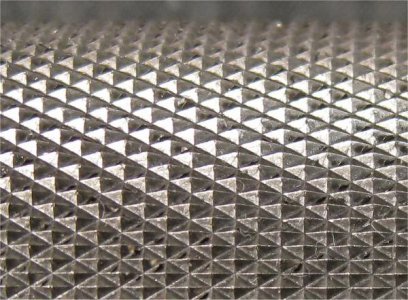

Thanks for the information your posts are always above and beyond what I expect. I'll just have to order some new wheels from accutrak of the same direction, just curious what TPI are you using for the single diagonal knurling shown in the flashlight and ice pick photos? I also noticed the accutrak are only sold in the convex shape, is that better for any material? or specific for just hard materials, I plan on mostly knurling aluminum and some low carbon steel, eventually might need to do some stainless.

I also have a PM1236 (your thread about the PM1236 really sold me on buying it, thanks again). You seem to knurl a lot of titanium, but have you found a sweet spot for RPM and feedrate for all knurling using the scissor type holder or do you have to constantly vary it for material and diameter?

One last question you mentioned you can induce double tracking to create the finer looking knurl, could you please elaborate on how this is done with a scissor knurl?

Best Regards,

John

Thanks for the information your posts are always above and beyond what I expect. I'll just have to order some new wheels from accutrak of the same direction, just curious what TPI are you using for the single diagonal knurling shown in the flashlight and ice pick photos? I also noticed the accutrak are only sold in the convex shape, is that better for any material? or specific for just hard materials, I plan on mostly knurling aluminum and some low carbon steel, eventually might need to do some stainless.

I also have a PM1236 (your thread about the PM1236 really sold me on buying it, thanks again). You seem to knurl a lot of titanium, but have you found a sweet spot for RPM and feedrate for all knurling using the scissor type holder or do you have to constantly vary it for material and diameter?

One last question you mentioned you can induce double tracking to create the finer looking knurl, could you please elaborate on how this is done with a scissor knurl?

Best Regards,

John