- Joined

- Jun 10, 2013

- Messages

- 115

Klutch Bandsaw Start-up

It was time to buy a 4x6 and after reading most of the reviews here I knew I was in for some work – lots of great tips. I previously posted on the “crooked vise” on the forum – decided to leave as is. Back to the start – it was back ordered but I was in no hurry, why this version? I knew they were all similar and I liked the color, oh, and it was the cheapest . Anyway, arrived in good order and was packaged well, the instructions are fairly useless but it’s mostly self explanatory.

. Anyway, arrived in good order and was packaged well, the instructions are fairly useless but it’s mostly self explanatory.

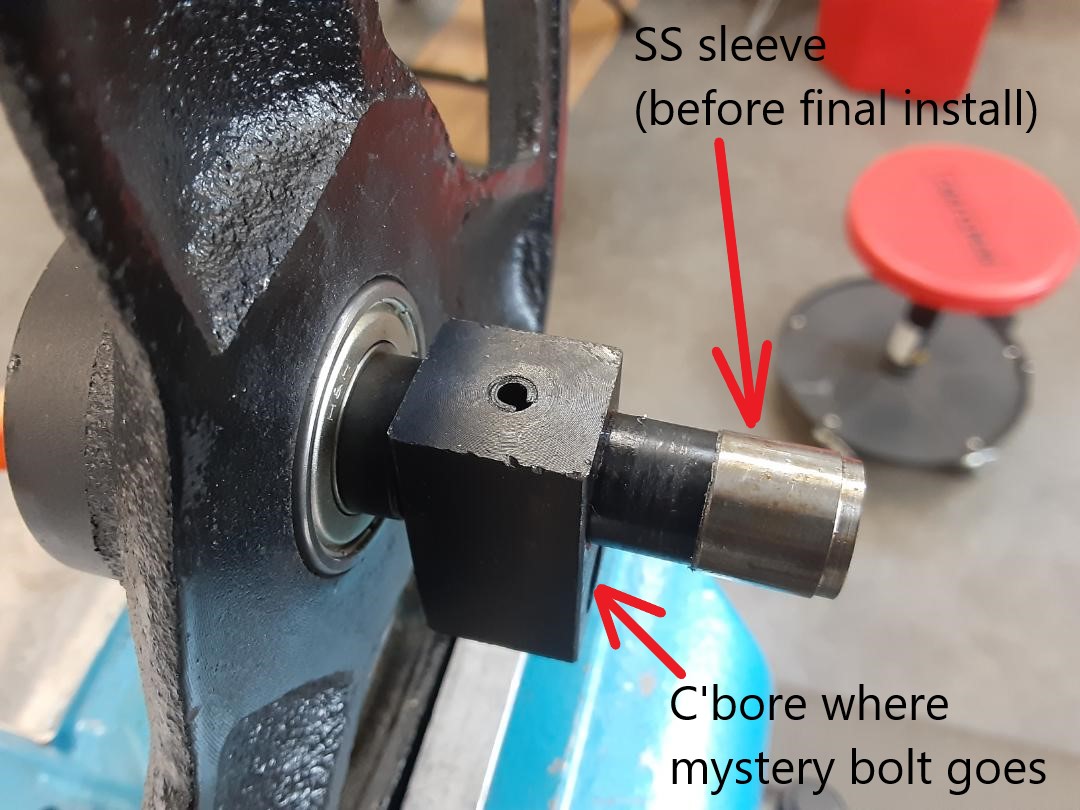

The first thing was to get a new bimetallic blade so that meant getting inside to take a look at things. The moveable pulley mounting is odd and a bit difficult to explain. The boss that fits into the movable mount has about .030” difference between the diameters – it just rattles – there is no way it should be like this – unless – that brings us to the mystery bolt. Bolt # 1 (see pic) holds the adjustor, that just stays tight. Bolt # 2 is the main pulley mount, Bolt #3 (the mystery bolt) goes into a c’bore on the sliding mount. If I had to take a guess this is for the pulley tracking but the execution is so poorly done it doesn’t make sense. When bolt # 2 is tightened it will always try to hold the pulley square – so is that why there is .030” slop? To allow for the “tilt”? I made (a very thin) stainless steel bushing to take this up, now it has a reasonable chance to stay in the center of that bore. I left the mystery bolt finger tight. Tracking is OK. There is enough slop in the sliding ways to null out any sort of alignment anyway.

“The Clamp” – other than the previously mentioned out of square, the front carrier for the screw shaft was in “backwards”. The bolt pattern is not centered on the carrier (made that way) and was not supporting the shaft as it should – I turned it around. I added a thrust washer on the handle end – there is only this tiny shoulder taking the entire load on the screw shaft. I milled about 0.020” off the clamp carrier as it would allow the movable jaw to rock excessively (so the jaw fits closer to flush with the table).

I added a table extension as well as a chip catch pan.

The stand was powder coated, from black to orange.

Vise jaws sand blasted and painted red.

Changed the crank handle – just for fun.

I added a spacer where the blade cover meets the frame – it’s off about a 1/8” and they just had a screw that mashed the sheet metal down to the frame when tight.

And finally I put it on a moveable machine tool dolly.

So… (editorial) this is a typical China tool. They can seem to make the big parts right but the details just go to hell. I am use to it by now and accept it knowing I will need to spend some time to make things right – you get what you pay for as the saying goes . It’s like they engineer/build 90% of it and forget the rest. Funny part is “the rest” costs almost nothing – 0.020” here, a washer there, a debur here. But it certainly gives me some satisfaction that I turned something relatively inexpensive into something that will work properly and reliably. Speaking of $:

$ 375 saw (includes tax)

$ 100 powder coat

$ 25 new blade

$ 60 tool dolly

$ 20 worth of AL

Round it off to $600.

So that’s it, let’s hope for many years of uneventful cutting!

It was time to buy a 4x6 and after reading most of the reviews here I knew I was in for some work – lots of great tips. I previously posted on the “crooked vise” on the forum – decided to leave as is. Back to the start – it was back ordered but I was in no hurry, why this version? I knew they were all similar and I liked the color, oh, and it was the cheapest

The first thing was to get a new bimetallic blade so that meant getting inside to take a look at things. The moveable pulley mounting is odd and a bit difficult to explain. The boss that fits into the movable mount has about .030” difference between the diameters – it just rattles – there is no way it should be like this – unless – that brings us to the mystery bolt. Bolt # 1 (see pic) holds the adjustor, that just stays tight. Bolt # 2 is the main pulley mount, Bolt #3 (the mystery bolt) goes into a c’bore on the sliding mount. If I had to take a guess this is for the pulley tracking but the execution is so poorly done it doesn’t make sense. When bolt # 2 is tightened it will always try to hold the pulley square – so is that why there is .030” slop? To allow for the “tilt”? I made (a very thin) stainless steel bushing to take this up, now it has a reasonable chance to stay in the center of that bore. I left the mystery bolt finger tight. Tracking is OK. There is enough slop in the sliding ways to null out any sort of alignment anyway.

“The Clamp” – other than the previously mentioned out of square, the front carrier for the screw shaft was in “backwards”. The bolt pattern is not centered on the carrier (made that way) and was not supporting the shaft as it should – I turned it around. I added a thrust washer on the handle end – there is only this tiny shoulder taking the entire load on the screw shaft. I milled about 0.020” off the clamp carrier as it would allow the movable jaw to rock excessively (so the jaw fits closer to flush with the table).

I added a table extension as well as a chip catch pan.

The stand was powder coated, from black to orange.

Vise jaws sand blasted and painted red.

Changed the crank handle – just for fun.

I added a spacer where the blade cover meets the frame – it’s off about a 1/8” and they just had a screw that mashed the sheet metal down to the frame when tight.

And finally I put it on a moveable machine tool dolly.

So… (editorial) this is a typical China tool. They can seem to make the big parts right but the details just go to hell. I am use to it by now and accept it knowing I will need to spend some time to make things right – you get what you pay for as the saying goes . It’s like they engineer/build 90% of it and forget the rest. Funny part is “the rest” costs almost nothing – 0.020” here, a washer there, a debur here. But it certainly gives me some satisfaction that I turned something relatively inexpensive into something that will work properly and reliably. Speaking of $:

$ 375 saw (includes tax)

$ 100 powder coat

$ 25 new blade

$ 60 tool dolly

$ 20 worth of AL

Round it off to $600.

So that’s it, let’s hope for many years of uneventful cutting!