- Joined

- Apr 20, 2015

- Messages

- 50

Hey all, Just signed up yesterday.

I've acquired a mini mill (craftex) and a B2227L 10X18 Metal Lathe.

As I am new to both tools, I figured I would start my own thread to pack with a series of questions as they inevitably unfold one by one in the coming weeks.

Firstly, I'm currently focused on the lathe, and learning how to use it.

------------------------

Background Below:

TLDR: $650 10X18 lathe + Enough tooling and accessories to keep me going for awhile.

------------------------

I posted an ad on Kijiji (Canadian Craigslist, but way better, lol) looking for a mini mill. Low and behold, someone offered one up. It was essentially new, used for a single project (make four replacement aluminum wheels for RC car) --> Due to the nature of wheels, it came with a rotary table. No tooling $400.

Updated the Kijiji Ad, "Have a mill, looking for a mini lathe"

Got a reply, someone's father passed away, B2227L 10X18, some tooling, $1400 firm. Kindly told him I was looking for a used mini lathe, so this was clearly outside of my budget. Kindly thanked him for his time.

Few weeks later, still hadn't been contacted with anyone selling a mini lathe, but had saved up a full $650 to buy one new. Figured it was a long shot, but emailed the above gentleman back explaining that I planned to buy a mini lathe the next day, but figured I would reach out to see if he could move on my low low low ball.

The look on my face when he called and said "Sure, I'll take your offer. I know it's a steal of a deal, but because you were so polite, I feel like I'm helping you get a leg up in metalworking."

Thought that was cool enough, until I showed up, and he had a drawer full of tooling, centers, chucks, collets, change gears etc. etc. He even through in a custom built bench with chip collection, and a green wheel bench grinder. $650!

Pic attached of one of three drawers with stuff in it.

------------------------

END Background

------------------------

------------------------

Question

------------------------

The lathe has these little ball bearing spots throughout. Are these places for lubricating oil?

Any preference for oil type?

The change gear axle bolt thing has one of these ball bearing spots too, it's also cracked and very very slowly leaking oil. What's my action plan for this?

Should I change the oil in the headstock, or don't worry about it?

Having troubles with threading, still learning all the details at the beginner forum. When threading my own stuff, it doesn't really matter which mm pitch I pick, as long as it's the same on both ends. The issue is if I want to match the thread of something else, correct?

--> Is there any way to convert this to Imperial? The largest learning curve for me is the metric stuff.

Alot of the tools are missing their brazed carbide insert. Is there any benefit of keeping these broken tools?

--> What steel are they made of? (Appropriate for turning them into little stock rods? "For science")

When feeding the tool into the part, is it better to use the compound to feed, or the Y access feed?

Thanks All! Glad to be part of the new community!

I've acquired a mini mill (craftex) and a B2227L 10X18 Metal Lathe.

As I am new to both tools, I figured I would start my own thread to pack with a series of questions as they inevitably unfold one by one in the coming weeks.

Firstly, I'm currently focused on the lathe, and learning how to use it.

------------------------

Background Below:

TLDR: $650 10X18 lathe + Enough tooling and accessories to keep me going for awhile.

------------------------

I posted an ad on Kijiji (Canadian Craigslist, but way better, lol) looking for a mini mill. Low and behold, someone offered one up. It was essentially new, used for a single project (make four replacement aluminum wheels for RC car) --> Due to the nature of wheels, it came with a rotary table. No tooling $400.

Updated the Kijiji Ad, "Have a mill, looking for a mini lathe"

Got a reply, someone's father passed away, B2227L 10X18, some tooling, $1400 firm. Kindly told him I was looking for a used mini lathe, so this was clearly outside of my budget. Kindly thanked him for his time.

Few weeks later, still hadn't been contacted with anyone selling a mini lathe, but had saved up a full $650 to buy one new. Figured it was a long shot, but emailed the above gentleman back explaining that I planned to buy a mini lathe the next day, but figured I would reach out to see if he could move on my low low low ball.

The look on my face when he called and said "Sure, I'll take your offer. I know it's a steal of a deal, but because you were so polite, I feel like I'm helping you get a leg up in metalworking."

Thought that was cool enough, until I showed up, and he had a drawer full of tooling, centers, chucks, collets, change gears etc. etc. He even through in a custom built bench with chip collection, and a green wheel bench grinder. $650!

Pic attached of one of three drawers with stuff in it.

------------------------

END Background

------------------------

------------------------

Question

------------------------

The lathe has these little ball bearing spots throughout. Are these places for lubricating oil?

Any preference for oil type?

The change gear axle bolt thing has one of these ball bearing spots too, it's also cracked and very very slowly leaking oil. What's my action plan for this?

Should I change the oil in the headstock, or don't worry about it?

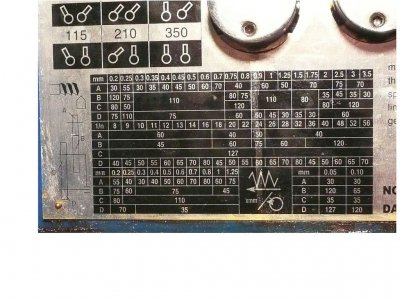

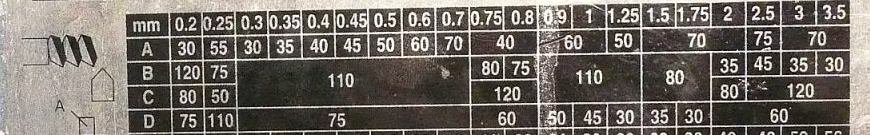

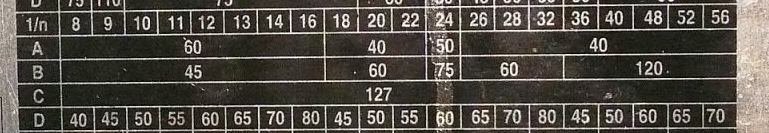

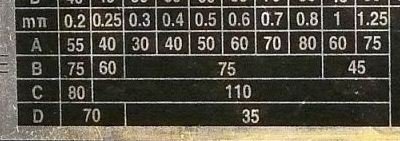

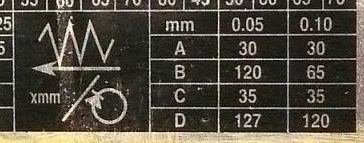

Having troubles with threading, still learning all the details at the beginner forum. When threading my own stuff, it doesn't really matter which mm pitch I pick, as long as it's the same on both ends. The issue is if I want to match the thread of something else, correct?

--> Is there any way to convert this to Imperial? The largest learning curve for me is the metric stuff.

Alot of the tools are missing their brazed carbide insert. Is there any benefit of keeping these broken tools?

--> What steel are they made of? (Appropriate for turning them into little stock rods? "For science")

When feeding the tool into the part, is it better to use the compound to feed, or the Y access feed?

Thanks All! Glad to be part of the new community!