- Joined

- Sep 22, 2010

- Messages

- 7,223

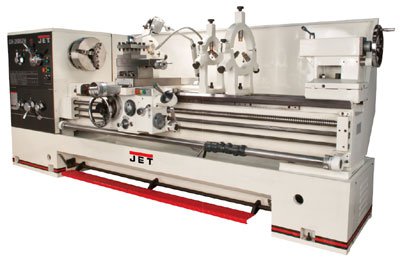

JET GHB-1340A Gear Head Bench Lathe

• Enclosed gearbox design provides smooth, quite operation

• Fast, easy speed changes

• Hardened and ground gears are featured in the headstock and gearbox

• D1-4 spindle is precision ground for accuracy and supported by high quality tapered roller bearings

• Headstock is constantly oiled during operation

• Gear box gives wide inch threading and feed capabilities with no gear changes

• V-way bed design is induction hardened and ground

• Gap bed section provided for larger diameter work Independent leadscrew and feed rod

• Spindle actuation control is apron-mounted

• Compound and cross slide have backlash elimination

• Adjustable gibs are incorporated in the carriage and slideways

• Tailstock may be offset for turning tapers and includes an inch-metric graduated quill

• Oil pan included

• Tolerance test certificate included

* Shown in photo with optional stand

• Swing Over Bed (inches) 13

• Swing Over Cross Slide (in.) 7-25/32

• Swing Through Gap 18-3/4

• Length Of Gap (in.) 8

• Distance Between Centers (in.) 40

• Hole Through Spindle (in.) 1-3/8

• Spindle Mount D1-4

• Spindle Taper (with Sleeve) MT-5(MT-3)

• Number Of Spindle Speeds 8

• Range Of Spindle Speeds 70 - 2000 rpm

• Longitudinal and Cross Feeds 40

• Longitudinal Feeds (in./rev).0036-.1005

• Cross Feeds (in./rev.) .0012 - .0345

• Number Of Inch Threads 40

• Range Of Inch Threads 4 - 112 T.P.I.

• Number Of Metric Threads 27

• Range Of Metric Threads (mm) 0.2 - 6

• Max. Tool Size (in.) 5/8 x 5/8

• Compound Slide Travel (in.) 2-11/16

• Cross Slide Travel (in.) 6-5/16

• Carriage Travel (in.) 35

• Tailstock Spindle Travel (in.) 3-3/4

• Taper in Tailstock Spindle MT-3

• Steady Rest Capacity (in.) 2-5/8

• Follow Rest Capacity (in.) 2-3/4

• Width Of Bed (in.) 7-3/8

• Size with Stand 71"L x 32"W x 47"H

• Main Motor 2 HP, 1 Phase, 230 Volts

• Net Weight (lbs.) 1,015

Options:

• Stand (shown in photo)

• Taper Turning attachment

• 5-C Lever Collet Closer

• 2 axis Digital Readout

JET GHB-1340W Gear Head Bench Lathe

• Uniquely designed exclusively by JET*

• Hardened and ground gears are featured in the headstock and gearbox

• Dl-4 spindle is precision ground for accuracy and supported by high-quality tapered roller bearings

• Headstock is constantly oiled during operation

• Splined, not keyed, shafts are utilized in the headstock

• Gearbox gives large threading and feed capabilities with no gear changes

• V-way bed design is induction hardened and ground

• Gap bed section provided for larger diameter work Independent leadscrew and feed rod

• Spindle actuation control is apron mounted Inch-metric dials are standard

• Compound and cross slide have backlash elimination

• Adjustable gibs in carriage and slideways

• Tailstock may be offset for turning tapers and includes an inch-metric graduated quill

• Tolerance test certificate included

STANDARD EQUIPMENT

• Heavy-Duty Stand

• 6" 3-Jaw Direct Mount Chuck w/Top Reversing Jaws

• 8" 4-Jaw Chuck

• 12" Face Plate

• Four-way Tool Post

• Steady Rest and Follow Rest

• Micro-Carriage Bed Stop

• Front Removable Chip Tray

• Spindle Jog Button

• Foot Brake

• Coolant System with Splash Guard

• Metric Change Gears

• Halogen Work Lamp

• Centers and Headstock Center Sleeve

• Threading Dial

• Tool Box and tools

• Swing Over Bed (inches) 13

• Swing Over Cross Slide (in.) 7-1/2

• Swing Through Gap (in.) 19

• Distance Between Centers (in.) 40

• Spindle Bore (in.) 1-1/2

• Spindle Mount Dl-4

• Spindle Taper (With Sleeve) MT5 (MT3)

• Number of Spindle Speeds 12

• Spindle Speeds Range 40 - 1800 rpm

• Number Longitudinal and Cross Feeds 40

• Range of Longitudinal Feeds (in./rev.) 0.0012 - 0.0294

• Crossfeeds Range (in./rev.)

0.0003 - 0.0103

• Number of Inch Threads 40

• Range of Inch Threads 4-112 TPI

• Number of Metric Threads 22

• Range of Metric Threads (mm) 0.45-7.5

• Maximum Tool Size (in.) 5/8 x 5/8"

• Maximum Compound Slide Travel 3-1/2"

• Maximum Cross Slide Travel (in.) 6-3/8

• Maximum Carriage Travel (in.) 37-1/2

• Tailstock Spindle Travel (in.) 4-3/4

• Taper in Tailstock Spindle MT-3

• Steady Rest Capacity (in.) 3-3/4

• Follow Rest Capacity (in.) 2-3/4

• Width of Bed (in.) 10-1/2

• Motor: 3 HP, 230 Volts, 1 Phase or

230 Volts, 3 Phase or 460 Volts, 3 Phase

• Size: 73-3/4"L x 29-1/2"W x 46-3/4"H

• Net Weight: 2081 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

JET GHB-1440W Gear Head Bench Lathe

• Uniquely designed exclusively by JET*

• Hardened and ground gears are featured in the headstock and gearbox

• Dl-4 spindle is precision ground for accuracy and supported by high-quality tapered roller bearings

• Headstock is constantly oiled during operation

• Splined, not keyed, shafts in the headstock

• Gearbox gives large threading and feed capabilities with no gear changes

• V-way bed design is induction hardened and ground

• Gap bed section provided for larger diameter work

• Independent leadscrew and feed rod

• Spindle actuation control is apron mounted Inch-metric dials are standard

• Compound and cross slide have backlash elimination

• Adjustable gibs are incorporated in the carriage and slideways

• Tailstock may be offset for turning tapers and includes an inch-metric graduated quill

• Tolerance test certificate included

STANDARD EQUIPMENT

• Heavy-Duty Stand

• 6" 3-Jaw Direct Mount Chuck with Top Reversing Jaws

• 8" 4-Jaw Chuck

• 12" Face Plate

• Four-way Tool Post

• Steady Rest and Follow Rest

• Micro-Carriage Bed Stop

• Front Removable Chip Tray

• Spindle Jog Button

• Foot Brake

• Coolant System with Splash Guard

• Metric Change Gears

• Halogen Work Lamp

• Centers and Headstock Center Sleeve

• Threading Dial

• Tool Box and tools

• Swing Over Bed (inches) 14

• Swing Over Cross Slide (in.) 8-1/2

• Swing Through Gap (in.) 20

• Distance Between Centers (in.) 40

• Spindle Bore (in.) 1-1/2

• Spindle Mount D1-4

• Spindle Taper(With Sleeve) MT5 (MT3)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 40 - 1800 rpm • Longitudinal and Cross Feeds 40

• Range of Longitudinal Feeds (in./rev.) 0.0012 - 0.0294

• Range of Crossfeeds (in./rev.)

0.0003 - 0.0103

• Number of Inch Threads 40

• Range of Inch Threads 4-112 TPI

• Number of Metric Threads 22

• Range of Metric Threads 0.45 - 7.5mm

• Maximum Tool Size (in.) 5/8 x 5/8

• Maximum Compound Slide Travel 3-1/2"

• Maximum Cross Slide Travel 6-3/8"

• Maximum Carriage Travel 37-1/2

• Tailstock Spindle Travel 4-3/4"

• Taper in Tailstock Spindle MT-3

• Steady Rest Capacity (in.) 3-3/4

• Follow Rest Capacity (in.) 2-3/4

• Width of Bed (in.) 10-1/2

• Motor 3 HP, 230 Volts, 1 Phase

• Size 73-3/4"L x 29-1/2"W x 47-1/2"H

• Net Weight 2191 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

JET GH-1440ZX & 1460ZX Gear Head Lathe

• Uniquely designed exclusively by JET*

• ISO 9001 certified manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads, no change gears required

• Carriage features one-shot lubrication and Turcite-B coating on bed sliding surfaces

• T-slotted compound slide with four-way tool post

• Heavy one-piece cast iron base absorbs vibration

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened and ground

• Removable gap allows up to 23-5/8" diameter work

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs

• Tolerance test certificate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 12" Face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial

• Mountingpads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center

• Tool box and adjusting tools

• Swing Over Bed (inches) 14

• Swing Over Cross Slide (in.) 7-5/8

• Swing Through Gap (in.) 23-5/8

• Length of Gap (in.) 12-1/4

• Distance Between Centers (in.) choose from 40 or 60

• Spindle Bore (in.) 3-1/8

• Spindle Mount D1-8

• Spindle Taper (with sleeve) MT7 (MT5)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 42 - 1800 rpm

• Longitudinal and Cross Feeds 122

• Range of Longitudinal Feeds (in./rev.) 0.0015 to 0.0913

• Range of Cross Feeds (in./rev.) 0.0006 to 0.0365

• Number of Inch Threads 61

• Range of Inch Threads 1-5/8 to 72

• Number of Metric Threads 24

• Range of Metric Threads (mm)0.05 - 20

• Maximim Tool Size (in.) 1x1

• Maximim Compound Slide Travel 5-1/8"

• Maximim Cross Slide Travel 9"

• Maximim Carriage Travel (in.) 35

• Tailstock Spindle Travel (in.) 5

• Tailstock Taper MT-4

• Follow Rest Capacity (in.) 1/2 to 3-1/2

• Steady Rest Capacity (in.) 3/8 to 7

• Width of Bed (in.) 13-3/8

• Overall Dimensions:

GH1640ZX: 97-1/2"L x 40"W x 46-7/8"H

GH1660ZX: 116-1/2"L x 40"W x 46-7/8"H

• Net Weight:

GH1640ZX: 5187 Lbs.

GH1660ZX: 5380 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

Click to request a quote for the

Jet GH1440ZX Lathe

Click to request a quote for the

Jet GH1460ZX Lathe

OR

Call 773-334-5000 to order

JET GH-1640ZX & 1660ZX Gear Head Lathe

• Uniquely designed exclusively by JET*

• ISO 9001 certified manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads, no change gears required

• Carriage features one-shot lubrication and Turcite-B coating on bed sliding surfaces

• T-slotted compound slide with four-way tool post

• Heavy one-piece cast iron base absorbs vibration

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened and ground

• Removable gap allows up to 25-7/8" diameter work

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs

• Tolerance test certificate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 12" Face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial

• Mountingpads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center

• Tool box and adjusting tools

• Swing Over Bed (inches) 16

• Swing Over Cross Slide (in.) 10

• Swing Through Gap (in.) 25-7/8

• Length of Gap (in.) 12-1/4

• Distance Between Centers (in.)

choose from 40 or 60

• Spindle Bore (in.) 3-1/8

• Spindle Mount D1-8

• Spindle Taper (with sleeve) MT7 (MT5)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 25 - 1800 rpm

• Longitudinal and Cross Feeds 122

• Range of Longitudinal Feeds (in./rev.) .0015 -.0913

• Range of Cross Feeds (in./rev.)

.0006 -.0365

• Number of Inch Threads 61

• Range of Inch Threads 1-5/8 to 72 tpi

• Number of Metric Threads 24

• Range of Metric Threads (mm) .05 - 20

• Maximim Tool Size (in.) 1 x 1

• Maximim Compound Slide Travel 5-1/8"

• Maximim Cross Slide Travel 9"

• Maximim Carriage Travel 35"

• Tailstock Spindle Travel 5"

• Tailstock Taper MT-4

• Follow Rest Capacity 1/2 - 3-1/2"

• Steady Rest Capacity 3/8 - 7"

• Width of Bed 13-3/8"

• Dimensions 97-1/2"L x 40"W x 48"H

• Motor: 7.5 HP, 3 Phase, 230V or 460V prewired 230 Volts

• Overall Dimensions:

GH1640ZX: 117"L x 40"W x 48-7/8"H

GH1660ZX: 136"L x 40"W x 48-7/8"H

• Net Weight:

GH1640ZX: 6245Lbs.

GH1660ZX: 6590 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

JET GH-1860ZX, GH-1880ZX Gear Head Lathes

• Uniquely designed exclusively by JET*

• ISO 9001 certified manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads, no change gears required

• Carriage features one-shot lubrication and Turcite-B on bed sliding surfaces

• T-slotted compound slide with 4-way tool post

• One-piece cast iron base absorbs vibration allowing heavier cuts

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened and ground

• Removable gap allows up to 27-1/2" diameter work

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs complete this impressive package

• Tolerance test certificate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 16" face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial Mounting pads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center Tool box and adjusting tools

• Swing Over Bed (inches) 18

• Swing Over Cross Slide (in.) 11

• Swing Through Gap (in.) 27-1/2

• Length of Gap (in.) 12-1/4

• Distance Between Centers (in.)

choose from 60 or 80

• Spindle Bore (in.) 3-1/8

• Spindle Mount D1-8

• Spindle Taper (with sleeve) MT7 (MT5)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 25 - 1800 rpm

• Longitudinal and Cross Feeds 122

• Range of Longitudinal Feeds (in./rev.) .0015 -.0913

• Range of Cross Feeds (in./rev.)

.0006 -.0365

• Number of Inch Threads 61

• Range of Inch Threads 1-5/8 -72 tpi

• Number of Metric Threads 24

• Range of Metric Threads (mm) .05 - 20

• Maximum Tool Size (in.) 1 x 1

• Maximum Compound Slide Travel 5-1/8"

• Maximum Cross Slide Travel (in.) 9

• Maximum Carriage Travel (in.) 35

• Tailstock Spindle Travel (in.) 5

• Tailstock Taper MT-5

• Follow Rest Capacity (in.) 1/2 to 3-1/2

• Steady Rest Capacity (in.) 3/8 to 7

• Width of Bed (in.) 13-3/8

• Motor: 7.5 HP, 3 Phase, 230V or 460V prewired 230 Volts

• Overall Dimensions:

GH1860ZX: 117"L x 40"W x 48-7/8"H

GH1880ZX: 136"L x 40"W x 48-7/8"H

• Net Weight:

GH1860ZX: 6245Lbs.

GH1880ZX: 6590 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

JET GH-2280ZX Gear Head Lathe

• Uniquely designed exclusively by JET*

• ISO 9001 certified manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads, no change gears required

• Carriage features one-shot lubrication and Turcite-B on bed sliding surfaces

• T-slotted compound slide featuring a four-way tool post

• One-piece cast iron base absorbs vibration allowing heavier cuts

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened and ground

• Removable gap allows up to 23-5/8" diameter work on 16", 27-1/2" on 18"

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs complete this impressive package

• Tolerance test certificate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 16" face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial

• Mounting pads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center

• Tool box and adjusting tools

• Swing Over Bed (inches) 22

• Swing Over Cross Slide (in.) 13

• Swing Through Gap (in.) 29 - 1/2

• Length of Gap (in.) 12-1/4

• Distance Between Centers (in.) 80

• Spindle Bore (in.) 3-1/8

• Spindle Mount D1-8

• Spindle Taper (with sleeve) MT7 (MT5)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 25 to 1800 rpm

• Longitudinal and Cross Feeds 122

• Range of Longitudinal Feeds (in./rev.) .0015 -.0913

• Range of Cross Feeds (in./rev.)

.0006 -.0365

• Number of Inch Threads 61

• Range of Inch Threads 1-5/8 to 72 tpi

• Number of Metric Threads 24

• Range of Metric Threads (mm) .05 - 20

• Maximum Tool Size (in.) 1 x 1

• Maximum Compound Slide Travel 5-1/8"

• Maximum Cross Slide Travel (in.) 10

• Maximum Carriage Travel (in.) 75

• Tailstock Spindle Travel (in.) 5

• Tailstock Taper MT-5

• Follow Rest Capacity (in.) 1/2 to 3-1/2

• Steady Rest Capacity (in.) 3/8 to 7

• Width of Bed (in.) 13-3/8

• Dimensions 136-1/8"L x 40"W x 48-7/8"H

• Motors 10 HP & 2 HP, 3 Phase, 230V or 460V, prewired 230 Volts

• Net Weight 7400 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

Click to request a quote for this machine

OR

Call 773-334-5000 to order this machine

JET GH-2680ZH 26 x 80" large metalworking Lathe

JET GH-26120ZH 26 x 120" longer Lathe machine

Standard Features:

* Large 4-1/8" Spindle Bore

* Turns 89 different thread sizes

* Clutch operated headstock with all headstock gears hardened and ground

* Bed ways are induction hardened and ground for durability

* Heavy-duty tailstock and quill

* One piece heavy-duty cast iron base and bed 12 speeds in range

* 36-1600 RPM Rapid power traverse to cross slide and carriage

* Headstock-gearbox designed for quick setup of thread turning operation without changing gears.

Standard Equipment:

12" 3-Jaw Direct Mount Scroll Chuck with Jaws

16" 4-Jaw Chuck

Face Plate

2 Steady Rests

Follow Rest

4 Way Tool Post

Coolant System

Full Length Splash Guard

Halogen Work Lamp

Swing over Bed (inches): 26

Swing over Cross Slide (inches): 16-1/2

Swing Through Gap (inches): 34

Length of Gap (inches): 8

Distance Between Centers (inches) 80 or 120"

Spindle Bore (inches): 4-1/8"

Spindle Mount: D1-8

Spindle Taper W/ Sleeve MT-5 (no sleeve)

Number of Spindle speeds: 12

Range of Spindle Speeds (RPM) 36-1600

Number of Longitudinal and Cross Feed Rates: 65

Range of Longitudinal Feeds (IPR)

.023-.937

Range of Cross Feeds (IPR) .010-.0404

Number of Inch Threads: 48

Range of Inch Threads (TPI) 2-30

Number of Metric Threads: 22

Range of Metric Threads: 1-14

Max Tool Size (inches): 1-1/4 x 1-1/4

Compound Slide Travel (inches): 5-1/2

Cross Slide Travel (inches): 12-3/32

Carriage Travel (inches):

GH-2680ZH: 72.5, GH-26120ZH: 108.25

Tailstock Spindle Travel (inches): 6

Taper in Tailstock Spindle: MT-5

Steady Rest Capacity (inches) Small 25/32 - 4-29/32, Large 3-15/16 - 9-7/16"

Follow Rest Capacity: 25/32 - 3-15/16"

Width of Bed (inches): 16

Motor: 10HP, choose 230V or 460Volts, 3 phase Prewired 230Volts

Width & Height Dimensions (inches):

43 Wide x 57 High

GH-2680ZH: 136" Long,

GH-26120ZH: 177" Long

Net Weight: GH-2680ZH: 8514 pounds, GH-26120ZH: 9362 pounds

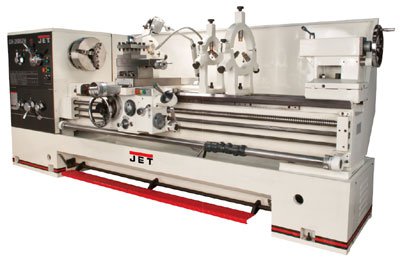

• Enclosed gearbox design provides smooth, quite operation

• Fast, easy speed changes

• Hardened and ground gears are featured in the headstock and gearbox

• D1-4 spindle is precision ground for accuracy and supported by high quality tapered roller bearings

• Headstock is constantly oiled during operation

• Gear box gives wide inch threading and feed capabilities with no gear changes

• V-way bed design is induction hardened and ground

• Gap bed section provided for larger diameter work Independent leadscrew and feed rod

• Spindle actuation control is apron-mounted

• Compound and cross slide have backlash elimination

• Adjustable gibs are incorporated in the carriage and slideways

• Tailstock may be offset for turning tapers and includes an inch-metric graduated quill

• Oil pan included

• Tolerance test certificate included

* Shown in photo with optional stand

• Swing Over Bed (inches) 13

• Swing Over Cross Slide (in.) 7-25/32

• Swing Through Gap 18-3/4

• Length Of Gap (in.) 8

• Distance Between Centers (in.) 40

• Hole Through Spindle (in.) 1-3/8

• Spindle Mount D1-4

• Spindle Taper (with Sleeve) MT-5(MT-3)

• Number Of Spindle Speeds 8

• Range Of Spindle Speeds 70 - 2000 rpm

• Longitudinal and Cross Feeds 40

• Longitudinal Feeds (in./rev).0036-.1005

• Cross Feeds (in./rev.) .0012 - .0345

• Number Of Inch Threads 40

• Range Of Inch Threads 4 - 112 T.P.I.

• Number Of Metric Threads 27

• Range Of Metric Threads (mm) 0.2 - 6

• Max. Tool Size (in.) 5/8 x 5/8

• Compound Slide Travel (in.) 2-11/16

• Cross Slide Travel (in.) 6-5/16

• Carriage Travel (in.) 35

• Tailstock Spindle Travel (in.) 3-3/4

• Taper in Tailstock Spindle MT-3

• Steady Rest Capacity (in.) 2-5/8

• Follow Rest Capacity (in.) 2-3/4

• Width Of Bed (in.) 7-3/8

• Size with Stand 71"L x 32"W x 47"H

• Main Motor 2 HP, 1 Phase, 230 Volts

• Net Weight (lbs.) 1,015

Options:

• Stand (shown in photo)

• Taper Turning attachment

• 5-C Lever Collet Closer

• 2 axis Digital Readout

JET GHB-1340W Gear Head Bench Lathe

• Uniquely designed exclusively by JET*

• Hardened and ground gears are featured in the headstock and gearbox

• Dl-4 spindle is precision ground for accuracy and supported by high-quality tapered roller bearings

• Headstock is constantly oiled during operation

• Splined, not keyed, shafts are utilized in the headstock

• Gearbox gives large threading and feed capabilities with no gear changes

• V-way bed design is induction hardened and ground

• Gap bed section provided for larger diameter work Independent leadscrew and feed rod

• Spindle actuation control is apron mounted Inch-metric dials are standard

• Compound and cross slide have backlash elimination

• Adjustable gibs in carriage and slideways

• Tailstock may be offset for turning tapers and includes an inch-metric graduated quill

• Tolerance test certificate included

STANDARD EQUIPMENT

• Heavy-Duty Stand

• 6" 3-Jaw Direct Mount Chuck w/Top Reversing Jaws

• 8" 4-Jaw Chuck

• 12" Face Plate

• Four-way Tool Post

• Steady Rest and Follow Rest

• Micro-Carriage Bed Stop

• Front Removable Chip Tray

• Spindle Jog Button

• Foot Brake

• Coolant System with Splash Guard

• Metric Change Gears

• Halogen Work Lamp

• Centers and Headstock Center Sleeve

• Threading Dial

• Tool Box and tools

• Swing Over Bed (inches) 13

• Swing Over Cross Slide (in.) 7-1/2

• Swing Through Gap (in.) 19

• Distance Between Centers (in.) 40

• Spindle Bore (in.) 1-1/2

• Spindle Mount Dl-4

• Spindle Taper (With Sleeve) MT5 (MT3)

• Number of Spindle Speeds 12

• Spindle Speeds Range 40 - 1800 rpm

• Number Longitudinal and Cross Feeds 40

• Range of Longitudinal Feeds (in./rev.) 0.0012 - 0.0294

• Crossfeeds Range (in./rev.)

0.0003 - 0.0103

• Number of Inch Threads 40

• Range of Inch Threads 4-112 TPI

• Number of Metric Threads 22

• Range of Metric Threads (mm) 0.45-7.5

• Maximum Tool Size (in.) 5/8 x 5/8"

• Maximum Compound Slide Travel 3-1/2"

• Maximum Cross Slide Travel (in.) 6-3/8

• Maximum Carriage Travel (in.) 37-1/2

• Tailstock Spindle Travel (in.) 4-3/4

• Taper in Tailstock Spindle MT-3

• Steady Rest Capacity (in.) 3-3/4

• Follow Rest Capacity (in.) 2-3/4

• Width of Bed (in.) 10-1/2

• Motor: 3 HP, 230 Volts, 1 Phase or

230 Volts, 3 Phase or 460 Volts, 3 Phase

• Size: 73-3/4"L x 29-1/2"W x 46-3/4"H

• Net Weight: 2081 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

JET GHB-1440W Gear Head Bench Lathe

• Uniquely designed exclusively by JET*

• Hardened and ground gears are featured in the headstock and gearbox

• Dl-4 spindle is precision ground for accuracy and supported by high-quality tapered roller bearings

• Headstock is constantly oiled during operation

• Splined, not keyed, shafts in the headstock

• Gearbox gives large threading and feed capabilities with no gear changes

• V-way bed design is induction hardened and ground

• Gap bed section provided for larger diameter work

• Independent leadscrew and feed rod

• Spindle actuation control is apron mounted Inch-metric dials are standard

• Compound and cross slide have backlash elimination

• Adjustable gibs are incorporated in the carriage and slideways

• Tailstock may be offset for turning tapers and includes an inch-metric graduated quill

• Tolerance test certificate included

STANDARD EQUIPMENT

• Heavy-Duty Stand

• 6" 3-Jaw Direct Mount Chuck with Top Reversing Jaws

• 8" 4-Jaw Chuck

• 12" Face Plate

• Four-way Tool Post

• Steady Rest and Follow Rest

• Micro-Carriage Bed Stop

• Front Removable Chip Tray

• Spindle Jog Button

• Foot Brake

• Coolant System with Splash Guard

• Metric Change Gears

• Halogen Work Lamp

• Centers and Headstock Center Sleeve

• Threading Dial

• Tool Box and tools

• Swing Over Bed (inches) 14

• Swing Over Cross Slide (in.) 8-1/2

• Swing Through Gap (in.) 20

• Distance Between Centers (in.) 40

• Spindle Bore (in.) 1-1/2

• Spindle Mount D1-4

• Spindle Taper(With Sleeve) MT5 (MT3)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 40 - 1800 rpm • Longitudinal and Cross Feeds 40

• Range of Longitudinal Feeds (in./rev.) 0.0012 - 0.0294

• Range of Crossfeeds (in./rev.)

0.0003 - 0.0103

• Number of Inch Threads 40

• Range of Inch Threads 4-112 TPI

• Number of Metric Threads 22

• Range of Metric Threads 0.45 - 7.5mm

• Maximum Tool Size (in.) 5/8 x 5/8

• Maximum Compound Slide Travel 3-1/2"

• Maximum Cross Slide Travel 6-3/8"

• Maximum Carriage Travel 37-1/2

• Tailstock Spindle Travel 4-3/4"

• Taper in Tailstock Spindle MT-3

• Steady Rest Capacity (in.) 3-3/4

• Follow Rest Capacity (in.) 2-3/4

• Width of Bed (in.) 10-1/2

• Motor 3 HP, 230 Volts, 1 Phase

• Size 73-3/4"L x 29-1/2"W x 47-1/2"H

• Net Weight 2191 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

JET GH-1440ZX & 1460ZX Gear Head Lathe

• Uniquely designed exclusively by JET*

• ISO 9001 certified manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads, no change gears required

• Carriage features one-shot lubrication and Turcite-B coating on bed sliding surfaces

• T-slotted compound slide with four-way tool post

• Heavy one-piece cast iron base absorbs vibration

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened and ground

• Removable gap allows up to 23-5/8" diameter work

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs

• Tolerance test certificate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 12" Face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial

• Mountingpads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center

• Tool box and adjusting tools

• Swing Over Bed (inches) 14

• Swing Over Cross Slide (in.) 7-5/8

• Swing Through Gap (in.) 23-5/8

• Length of Gap (in.) 12-1/4

• Distance Between Centers (in.) choose from 40 or 60

• Spindle Bore (in.) 3-1/8

• Spindle Mount D1-8

• Spindle Taper (with sleeve) MT7 (MT5)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 42 - 1800 rpm

• Longitudinal and Cross Feeds 122

• Range of Longitudinal Feeds (in./rev.) 0.0015 to 0.0913

• Range of Cross Feeds (in./rev.) 0.0006 to 0.0365

• Number of Inch Threads 61

• Range of Inch Threads 1-5/8 to 72

• Number of Metric Threads 24

• Range of Metric Threads (mm)0.05 - 20

• Maximim Tool Size (in.) 1x1

• Maximim Compound Slide Travel 5-1/8"

• Maximim Cross Slide Travel 9"

• Maximim Carriage Travel (in.) 35

• Tailstock Spindle Travel (in.) 5

• Tailstock Taper MT-4

• Follow Rest Capacity (in.) 1/2 to 3-1/2

• Steady Rest Capacity (in.) 3/8 to 7

• Width of Bed (in.) 13-3/8

• Overall Dimensions:

GH1640ZX: 97-1/2"L x 40"W x 46-7/8"H

GH1660ZX: 116-1/2"L x 40"W x 46-7/8"H

• Net Weight:

GH1640ZX: 5187 Lbs.

GH1660ZX: 5380 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

Click to request a quote for the

Jet GH1440ZX Lathe

Click to request a quote for the

Jet GH1460ZX Lathe

OR

Call 773-334-5000 to order

JET GH-1640ZX & 1660ZX Gear Head Lathe

• Uniquely designed exclusively by JET*

• ISO 9001 certified manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads, no change gears required

• Carriage features one-shot lubrication and Turcite-B coating on bed sliding surfaces

• T-slotted compound slide with four-way tool post

• Heavy one-piece cast iron base absorbs vibration

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened and ground

• Removable gap allows up to 25-7/8" diameter work

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs

• Tolerance test certificate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 12" Face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial

• Mountingpads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center

• Tool box and adjusting tools

• Swing Over Bed (inches) 16

• Swing Over Cross Slide (in.) 10

• Swing Through Gap (in.) 25-7/8

• Length of Gap (in.) 12-1/4

• Distance Between Centers (in.)

choose from 40 or 60

• Spindle Bore (in.) 3-1/8

• Spindle Mount D1-8

• Spindle Taper (with sleeve) MT7 (MT5)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 25 - 1800 rpm

• Longitudinal and Cross Feeds 122

• Range of Longitudinal Feeds (in./rev.) .0015 -.0913

• Range of Cross Feeds (in./rev.)

.0006 -.0365

• Number of Inch Threads 61

• Range of Inch Threads 1-5/8 to 72 tpi

• Number of Metric Threads 24

• Range of Metric Threads (mm) .05 - 20

• Maximim Tool Size (in.) 1 x 1

• Maximim Compound Slide Travel 5-1/8"

• Maximim Cross Slide Travel 9"

• Maximim Carriage Travel 35"

• Tailstock Spindle Travel 5"

• Tailstock Taper MT-4

• Follow Rest Capacity 1/2 - 3-1/2"

• Steady Rest Capacity 3/8 - 7"

• Width of Bed 13-3/8"

• Dimensions 97-1/2"L x 40"W x 48"H

• Motor: 7.5 HP, 3 Phase, 230V or 460V prewired 230 Volts

• Overall Dimensions:

GH1640ZX: 117"L x 40"W x 48-7/8"H

GH1660ZX: 136"L x 40"W x 48-7/8"H

• Net Weight:

GH1640ZX: 6245Lbs.

GH1660ZX: 6590 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

JET GH-1860ZX, GH-1880ZX Gear Head Lathes

• Uniquely designed exclusively by JET*

• ISO 9001 certified manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads, no change gears required

• Carriage features one-shot lubrication and Turcite-B on bed sliding surfaces

• T-slotted compound slide with 4-way tool post

• One-piece cast iron base absorbs vibration allowing heavier cuts

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened and ground

• Removable gap allows up to 27-1/2" diameter work

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs complete this impressive package

• Tolerance test certificate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 16" face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial Mounting pads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center Tool box and adjusting tools

• Swing Over Bed (inches) 18

• Swing Over Cross Slide (in.) 11

• Swing Through Gap (in.) 27-1/2

• Length of Gap (in.) 12-1/4

• Distance Between Centers (in.)

choose from 60 or 80

• Spindle Bore (in.) 3-1/8

• Spindle Mount D1-8

• Spindle Taper (with sleeve) MT7 (MT5)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 25 - 1800 rpm

• Longitudinal and Cross Feeds 122

• Range of Longitudinal Feeds (in./rev.) .0015 -.0913

• Range of Cross Feeds (in./rev.)

.0006 -.0365

• Number of Inch Threads 61

• Range of Inch Threads 1-5/8 -72 tpi

• Number of Metric Threads 24

• Range of Metric Threads (mm) .05 - 20

• Maximum Tool Size (in.) 1 x 1

• Maximum Compound Slide Travel 5-1/8"

• Maximum Cross Slide Travel (in.) 9

• Maximum Carriage Travel (in.) 35

• Tailstock Spindle Travel (in.) 5

• Tailstock Taper MT-5

• Follow Rest Capacity (in.) 1/2 to 3-1/2

• Steady Rest Capacity (in.) 3/8 to 7

• Width of Bed (in.) 13-3/8

• Motor: 7.5 HP, 3 Phase, 230V or 460V prewired 230 Volts

• Overall Dimensions:

GH1860ZX: 117"L x 40"W x 48-7/8"H

GH1880ZX: 136"L x 40"W x 48-7/8"H

• Net Weight:

GH1860ZX: 6245Lbs.

GH1880ZX: 6590 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

JET GH-2280ZX Gear Head Lathe

• Uniquely designed exclusively by JET*

• ISO 9001 certified manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads, no change gears required

• Carriage features one-shot lubrication and Turcite-B on bed sliding surfaces

• T-slotted compound slide featuring a four-way tool post

• One-piece cast iron base absorbs vibration allowing heavier cuts

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened and ground

• Removable gap allows up to 23-5/8" diameter work on 16", 27-1/2" on 18"

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs complete this impressive package

• Tolerance test certificate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 16" face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial

• Mounting pads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center

• Tool box and adjusting tools

• Swing Over Bed (inches) 22

• Swing Over Cross Slide (in.) 13

• Swing Through Gap (in.) 29 - 1/2

• Length of Gap (in.) 12-1/4

• Distance Between Centers (in.) 80

• Spindle Bore (in.) 3-1/8

• Spindle Mount D1-8

• Spindle Taper (with sleeve) MT7 (MT5)

• Number of Spindle Speeds 12

• Range of Spindle Speeds 25 to 1800 rpm

• Longitudinal and Cross Feeds 122

• Range of Longitudinal Feeds (in./rev.) .0015 -.0913

• Range of Cross Feeds (in./rev.)

.0006 -.0365

• Number of Inch Threads 61

• Range of Inch Threads 1-5/8 to 72 tpi

• Number of Metric Threads 24

• Range of Metric Threads (mm) .05 - 20

• Maximum Tool Size (in.) 1 x 1

• Maximum Compound Slide Travel 5-1/8"

• Maximum Cross Slide Travel (in.) 10

• Maximum Carriage Travel (in.) 75

• Tailstock Spindle Travel (in.) 5

• Tailstock Taper MT-5

• Follow Rest Capacity (in.) 1/2 to 3-1/2

• Steady Rest Capacity (in.) 3/8 to 7

• Width of Bed (in.) 13-3/8

• Dimensions 136-1/8"L x 40"W x 48-7/8"H

• Motors 10 HP & 2 HP, 3 Phase, 230V or 460V, prewired 230 Volts

• Net Weight 7400 Lbs.

OPTIONS:

• 2 axis Digital Readout

• Quick change tool post

• 5-C Lever Collet Closer

• Taper Attachment

• Live Center

Click to request a quote for this machine

OR

Call 773-334-5000 to order this machine

JET GH-2680ZH 26 x 80" large metalworking Lathe

JET GH-26120ZH 26 x 120" longer Lathe machine

Standard Features:

* Large 4-1/8" Spindle Bore

* Turns 89 different thread sizes

* Clutch operated headstock with all headstock gears hardened and ground

* Bed ways are induction hardened and ground for durability

* Heavy-duty tailstock and quill

* One piece heavy-duty cast iron base and bed 12 speeds in range

* 36-1600 RPM Rapid power traverse to cross slide and carriage

* Headstock-gearbox designed for quick setup of thread turning operation without changing gears.

Standard Equipment:

12" 3-Jaw Direct Mount Scroll Chuck with Jaws

16" 4-Jaw Chuck

Face Plate

2 Steady Rests

Follow Rest

4 Way Tool Post

Coolant System

Full Length Splash Guard

Halogen Work Lamp

Swing over Bed (inches): 26

Swing over Cross Slide (inches): 16-1/2

Swing Through Gap (inches): 34

Length of Gap (inches): 8

Distance Between Centers (inches) 80 or 120"

Spindle Bore (inches): 4-1/8"

Spindle Mount: D1-8

Spindle Taper W/ Sleeve MT-5 (no sleeve)

Number of Spindle speeds: 12

Range of Spindle Speeds (RPM) 36-1600

Number of Longitudinal and Cross Feed Rates: 65

Range of Longitudinal Feeds (IPR)

.023-.937

Range of Cross Feeds (IPR) .010-.0404

Number of Inch Threads: 48

Range of Inch Threads (TPI) 2-30

Number of Metric Threads: 22

Range of Metric Threads: 1-14

Max Tool Size (inches): 1-1/4 x 1-1/4

Compound Slide Travel (inches): 5-1/2

Cross Slide Travel (inches): 12-3/32

Carriage Travel (inches):

GH-2680ZH: 72.5, GH-26120ZH: 108.25

Tailstock Spindle Travel (inches): 6

Taper in Tailstock Spindle: MT-5

Steady Rest Capacity (inches) Small 25/32 - 4-29/32, Large 3-15/16 - 9-7/16"

Follow Rest Capacity: 25/32 - 3-15/16"

Width of Bed (inches): 16

Motor: 10HP, choose 230V or 460Volts, 3 phase Prewired 230Volts

Width & Height Dimensions (inches):

43 Wide x 57 High

GH-2680ZH: 136" Long,

GH-26120ZH: 177" Long

Net Weight: GH-2680ZH: 8514 pounds, GH-26120ZH: 9362 pounds