-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is This What A Machined Surface Should Look Like?

- Thread starter HBilly1022

- Start date

- Joined

- Nov 27, 2015

- Messages

- 603

I suspect the 30 days/unused return policy is for buyer's remorse. You are dealing with something that has required numerous warranty parts replacements and even one total replacement within 90 days, well within the warranty period. I still think you should be able to demand a full refund. If you want to be nice you can ask for credit toward a new machine but only if you can inspect the new machine before receiving it. I suspect the dealer is just hoping you don't. He's only out his cost; you're out the full price.I can't take it back. Company policy is 30 days from purchase date and it must be unused. Even if I could take it back then what? The only options around here are; 1) get another King Product, 2) get a Busy Bee product, 3) get a new southbend (no way on earth am I spending that much for a hobby lathe that only gets occasional use) or 4) get something used. The used stuff around here is very pricey or garbage in my price range. Doesn't leave many viable options. The only realistic option that I see at this stage is to get a new saddle that is properly made and carry on with this lathe. As I noted earlier, there have been a lot of issues with this lathe that I have worked through and I hope this is the last one.

Steve Shannon

Steve Shannon

- Joined

- Dec 22, 2015

- Messages

- 561

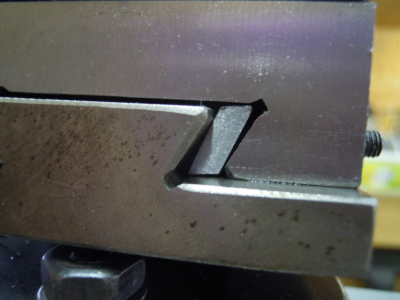

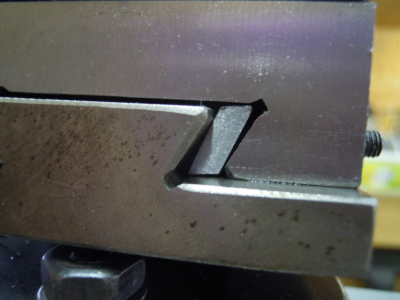

It just keeps getting better. I go out to the shop to continue working on my mill handle project and find that the compound slide is binding again. So I take it apart to clean it and inspect for possible causes. The first thing I notice is that the gib is bowed and it has a wear line close to the top edge. Now I'm getting fed up. So I decide to start documenting things in case I end up in a fight with the manufacturer. I put the gib on the lathe ways and measure the bend. I zero the DTI on one end then take readings at the high point and other end. The middle is 0.028" higher. Then I place the gib on the cross slide ways and see that the wear line on the gib matches up with the top of the cross slide dovetail. I put it back together and the problem becomes obvious. You can see in one of the pics that the gib is not sitting flat against the cross slide dovetail. It appears that the gib adjusters are causing the gib to sit crooked on the dovetail.

I think I've had it with this lathe. I'm going into the City tomorrow and will go to the dealer to discuss this with him. I am tired of trouble shooting and then fixing my new lathe. I am going to suggest I get a refund and he can pursue this with the manufacturer. There is no way there should be this many issues with one lathe. This may not go well but I will let you know what comes of it. Worst case scenario they get the defective parts in and I will replace them for one last try. Best case scenario I get my money back ......... then what. I won't have a lathe. Anyways here are some pics for your enjoyment.

I think I've had it with this lathe. I'm going into the City tomorrow and will go to the dealer to discuss this with him. I am tired of trouble shooting and then fixing my new lathe. I am going to suggest I get a refund and he can pursue this with the manufacturer. There is no way there should be this many issues with one lathe. This may not go well but I will let you know what comes of it. Worst case scenario they get the defective parts in and I will replace them for one last try. Best case scenario I get my money back ......... then what. I won't have a lathe. Anyways here are some pics for your enjoyment.

- Joined

- Dec 2, 2012

- Messages

- 1,721

That looks like a design flaw. It looks like the gib is too small and the grub screws are way too high.

yeah does a bit, maybe they took too much off when machining the dovetail.

Good luck with the sales rep. I relay think it has to be a massive "fell through the Q.C." issue I can't see that the manufacturer would expect to put out a product like that.

That part (top slide / compound slide) doesn't have the same bubbly nature / machined with angle grinder and cold chisels look as the other parts, that should be about the roughest a slide way should look, the course nature of the fly cut(or maybe large shell mill) can help with oil retention, the ways, dovetails and gibs do have to be fairly tight with regard to overall flatness and angles etc. Some machines can have oil retention pockets hand chiseled in but their normaly more like oil grooves in a plain type bearing.

Stuart

- Joined

- Dec 22, 2015

- Messages

- 561

So before going back to the dealer I check with Busy Bee to see if they have the similar lathe in stock and on display. I explained my situation and asked if I could take the compound apart to check the machining before buying the lathe and the answer was NO. He suggested I look at the next model up that they have on display and I could look at it and use all the movements but not take anything apart. They have one of the similar models coming in and it should arrive in the next day or so. However I would have to trust that the machine was properly made and if not I could return it within 30 days if it was unused. However it had been opened there would be a 15% restocking fee. So $360 to restock it. Not much help or encouragement from them. So my options are 1) get my money back, 2) get a new replacement lathe from King or 3) get replacement parts for the ones I find defective.

Off to the dealers I go. I talk to the store owner and show him the defective parts (I took them with me). As expected he does not know how these parts are supposed to look and asks me questions like; how is the gib supposed to sit on the dovetail? Is there something wrong with the one he is looking at. That being pic 2 above. When he looks at the underside of the saddle he asks if I did something to it and then asks if it's supposed to look different. I said that I have a milling machine that I bought from him and if I did something to it, it would look like it was properly milled but I am not going to do anything that drastic because after that I own the problem. I explained my dilemma about getting my money back and getting something else but there weren't any good alternative lathe manufacturers that had any better reps (in that price range). So I could ask for a new lathe or get replacement parts for the ones I showed him. I wasn't sure I wanted to get another lathe becuase there has been a lot of other work I have already put into making this one better (functional) and didn't want to start that process over. He was open to all of my suggestions, even getting a refund but he would have to clear all the options with the King rep. He said he was sure the rep would tell me to just keep using the lathe the way it until something breaks or the lathe becomes unusable. I said no way. The warranty states that defective parts will be repaired or replaced during the warranty period. If I continue to use it then other parts will be negatively affected and there will be more parts to replace. Besides with that attitude I may not get the parts replaced before the warranty expires. That is a no go in my mind. Then he suggested I send him a fax with the part numbers I want replaced and he will discuss it with the King rep the next time he is in. After some more thought I'm not sure if I should get them to send me a whole new lathe or just the parts for this one. More thought required on my part.

I wish I had better new lathe options, in the same price range.

Jim; I told the dealer that I had posted pics on a machining forum to get feedback about these issues and I told him what you said about the compound gib problem but he didn't seem to understand. I sure do though and it makes a lot of sense to me. I don't think the dealer / owner is trying to act like he doesn't know, just to deflect the issue. I believe he is trying to do the right thing but honestly doesn't know. That doesn't help but I'm glad he is not being a jerk about this.

Off to the dealers I go. I talk to the store owner and show him the defective parts (I took them with me). As expected he does not know how these parts are supposed to look and asks me questions like; how is the gib supposed to sit on the dovetail? Is there something wrong with the one he is looking at. That being pic 2 above. When he looks at the underside of the saddle he asks if I did something to it and then asks if it's supposed to look different. I said that I have a milling machine that I bought from him and if I did something to it, it would look like it was properly milled but I am not going to do anything that drastic because after that I own the problem. I explained my dilemma about getting my money back and getting something else but there weren't any good alternative lathe manufacturers that had any better reps (in that price range). So I could ask for a new lathe or get replacement parts for the ones I showed him. I wasn't sure I wanted to get another lathe becuase there has been a lot of other work I have already put into making this one better (functional) and didn't want to start that process over. He was open to all of my suggestions, even getting a refund but he would have to clear all the options with the King rep. He said he was sure the rep would tell me to just keep using the lathe the way it until something breaks or the lathe becomes unusable. I said no way. The warranty states that defective parts will be repaired or replaced during the warranty period. If I continue to use it then other parts will be negatively affected and there will be more parts to replace. Besides with that attitude I may not get the parts replaced before the warranty expires. That is a no go in my mind. Then he suggested I send him a fax with the part numbers I want replaced and he will discuss it with the King rep the next time he is in. After some more thought I'm not sure if I should get them to send me a whole new lathe or just the parts for this one. More thought required on my part.

I wish I had better new lathe options, in the same price range.

Jim; I told the dealer that I had posted pics on a machining forum to get feedback about these issues and I told him what you said about the compound gib problem but he didn't seem to understand. I sure do though and it makes a lot of sense to me. I don't think the dealer / owner is trying to act like he doesn't know, just to deflect the issue. I believe he is trying to do the right thing but honestly doesn't know. That doesn't help but I'm glad he is not being a jerk about this.

T

TOOLMASTER

Forum Guest

Register Today

DOES THE COMPANY HAVE A FACEBOOK PAGE?

- Joined

- Dec 22, 2015

- Messages

- 561

I'm going through the Grizzly forum to see if I can find some pics of similar issues and come across a new thread by Planeflyer that shows the underside of his G4003 tailstock and it looks like similar machining to that on the underside of my saddle. http://www.hobby-machinist.com/attachments/tsclampnut-jpg.124191/ Is this normal for these import lathes? Am I expecting too much? I don't want to be causing a ruckus if it is not warranted but I also don't want to keep something that will become a problem. Maybe all of these lathes look like that on the undercarriage of the saddle and tailstock. I don't have any other references to view since my dealer does not have any lathes on display.

Toolmaster; no facebook page that I could find.

Toolmaster; no facebook page that I could find.

Last edited:

Best case scenario I get my money back ......... then what. I won't have a lathe.

Looks to me like you currently don't have lathe anyway.

Sent from my SM-N920C using Tapatalk