- Joined

- Jan 4, 2021

- Messages

- 912

A while back I picked up a 2J variable speed series 1 machine as a project. I had to have the motor shaft replaced because they key had come loose. Not exactly sure how that happened, but I got it for what I think is deal.

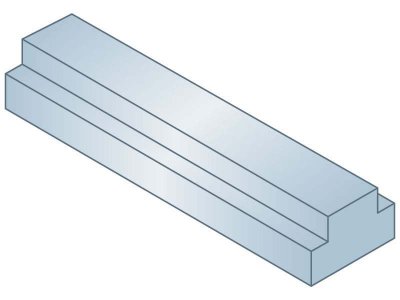

I’m contemplating if I NEED to replace the adjustable disc assembly. Are these key ways too damaged to use again? At least for the short term? The replacement is $230.

I’m contemplating if I NEED to replace the adjustable disc assembly. Are these key ways too damaged to use again? At least for the short term? The replacement is $230.