-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE MAIN DISCUSSION SECTION

- A BEGINNER'S FORUM (Learn How To Machine Here!)

- Beginner's forum Archive

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this normal?

- Thread starter Coomba

- Start date

- Joined

- Aug 6, 2013

- Messages

- 153

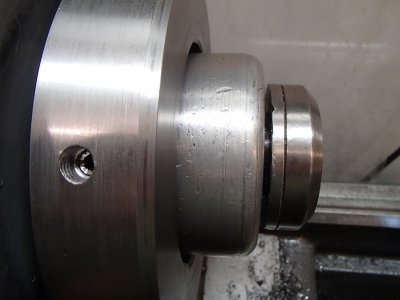

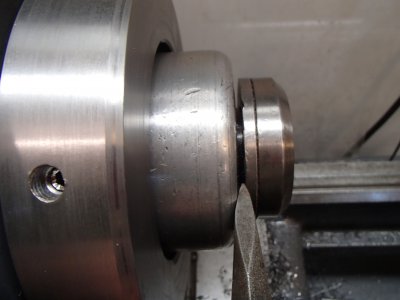

I think the nose protector should push the collet holder out the the spindle when you unscrew it.

I unscrewd the collet assembly from the collet,and the collet came out very easily. Then I removed the collet assembly from the lathe, set it on the floor. Then loosened the chuck collar.The bushing still would not come out,and the nose protector would not come completly loose. I had to pry bushing out with a very large screw driver.Then I could remove the spindle protector.

- Joined

- Feb 8, 2014

- Messages

- 11,144

I have only done this one time on that type of spindle, and that was years ago. But if I remember right, I tightened the nose protector pretty tight against the collet holder, then tapped it (OK, maybe more than a tap) with a hammer to get to pop loose.

It may be that this has always been a problem on your lathe and that is why the spanner holes were so torn up in your nut.

It may be that this has always been a problem on your lathe and that is why the spanner holes were so torn up in your nut.

B

Bill Gruby

Forum Guest

Register Today

Ditto on what Jim said.

"Billy G"

"Billy G"

- Joined

- Mar 19, 2014

- Messages

- 2,680

I agree with ki4byz. It looks like you have a L * mount? You can’t always use the nose guard to help in the removal of a taper adapter, dead center, etc. Best to have a piece of round stock that will fit through the spindle hole so you can knock the adapter out. If the round stock is steel you can add a brass end/head to it so you protect what you hit. And maybe a rubber/plastic bicycle hand for the other end for that sexy look…Good Luck.

- Joined

- Aug 6, 2013

- Messages

- 153

I use a rod through the spindle from the rear and a few bumps and the collect adapter should pop right out.

Thanks guys. Just wanted to make sure I wasn't doing something wrong!

My Hendey has a collet adapter in an L style head. It cannot be pushed out from behind because its through hole is larger than the through hole in the headstock. I have a forked wedge that slides into the gap and a light tap pops it free. Much like a ball joint or tie rod splitting tool. OK thats my two cents.

- Joined

- Aug 6, 2013

- Messages

- 153

My Hendey has a collet adapter in an L style head. It cannot be pushed out from behind because its through hole is larger than the through hole in the headstock. I have a forked wedge that slides into the gap and a light tap pops it free. Much like a ball joint or tie rod splitting tool. OK thats my two cents.

Have a picture?