- Joined

- Dec 26, 2016

- Messages

- 2,015

I have a used Albrecht chuck that I recieved from a kind member here (Bill/bfd) it wasn't too hard to get it cleaned up ,it now has a new collar, ready to be used but now I'm planning on mounting it on my Ridgid drill press ,here comes the problem: the hole is too too small for the drill press arbor, the way it is ,it can not be used with my DP.

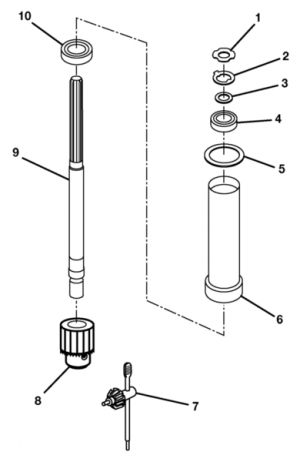

The Albrecht chuck has a J6 hole and the drill press arbor is JT#3, I was thinking if I had an adaptor that had a JT3 hole on one end and J6 arbor on the other end, it would work, I looked on ebay and a couple of other places but couldn't find anything like that.

Does anyone have any other ideas on how to mount a J6 chuck to aJT3 arbor? another possibility is to remove the arbor from the drill press and put it on a lathe and machine the end to a J6 but I can't do that job,don't have enough experience to do it plus I don't have a lathe .

If any of you could machine an adaptor for me I'll be more than happy to cover the cost, this pic below is more or less what I'm talking about:

I see all kinds f arbors but noone seems to make the adaptors unless I have been looking at the wrong places.

Can you help/

Thanks.

The Albrecht chuck has a J6 hole and the drill press arbor is JT#3, I was thinking if I had an adaptor that had a JT3 hole on one end and J6 arbor on the other end, it would work, I looked on ebay and a couple of other places but couldn't find anything like that.

Does anyone have any other ideas on how to mount a J6 chuck to aJT3 arbor? another possibility is to remove the arbor from the drill press and put it on a lathe and machine the end to a J6 but I can't do that job,don't have enough experience to do it plus I don't have a lathe .

If any of you could machine an adaptor for me I'll be more than happy to cover the cost, this pic below is more or less what I'm talking about:

I see all kinds f arbors but noone seems to make the adaptors unless I have been looking at the wrong places.

Can you help/

Thanks.