- Joined

- Oct 14, 2013

- Messages

- 1,009

Oh, great fount of machining wisdom

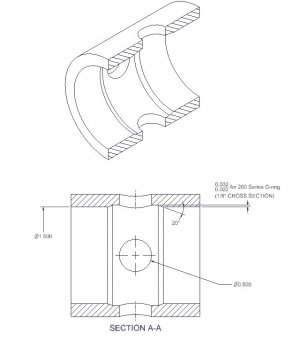

I need ideas on how to generate a 15 degree O-ring lead in chamfer around an internal hole.

I've got a roughly 1.5" bore with four, 1/2" holes crossing it (all in one plane). I need to copy what's in the photo, but in PTFE. I can't buy it... that would be too easy!

I need those four holes to have a decently uniform lead in around them so that a plug with O-rings rotating in the big bore does not have its O-ring bitten off by the holes. It's NOT a 45 degree chamfer.

The challenge is that I can't just rotate a shallow angle countersink at one position; the path is curved.

It's OK to spend real $$ on solving this...

Ideas?

Sent from my SM-G715A using Tapatalk

I need ideas on how to generate a 15 degree O-ring lead in chamfer around an internal hole.

I've got a roughly 1.5" bore with four, 1/2" holes crossing it (all in one plane). I need to copy what's in the photo, but in PTFE. I can't buy it... that would be too easy!

I need those four holes to have a decently uniform lead in around them so that a plug with O-rings rotating in the big bore does not have its O-ring bitten off by the holes. It's NOT a 45 degree chamfer.

The challenge is that I can't just rotate a shallow angle countersink at one position; the path is curved.

It's OK to spend real $$ on solving this...

Ideas?

Sent from my SM-G715A using Tapatalk