Hello,

I've noticed that if I do interrupted cuts then the chuck can be very difficult to remove.

Other people have told me that have similar problems with slitting saws and once when I was trying to make a cog I used a chuck mounted flycutter to cut the valleys between the teeth this also jammed the chuck.

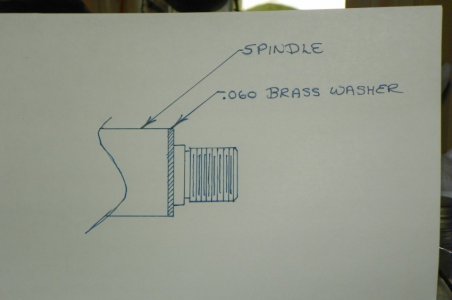

Is there any sense in putting some sort of washer (rubber, cardboard, other) between the chuck and the lathe to try to stop this ? Or is this a silly idea ?

I've noticed that if I do interrupted cuts then the chuck can be very difficult to remove.

Other people have told me that have similar problems with slitting saws and once when I was trying to make a cog I used a chuck mounted flycutter to cut the valleys between the teeth this also jammed the chuck.

Is there any sense in putting some sort of washer (rubber, cardboard, other) between the chuck and the lathe to try to stop this ? Or is this a silly idea ?