I inherited one of these lathe's from my dad, and am interested in getting into metalworking, for repairing and creating equipment and custom parts for my landscaping business and home.

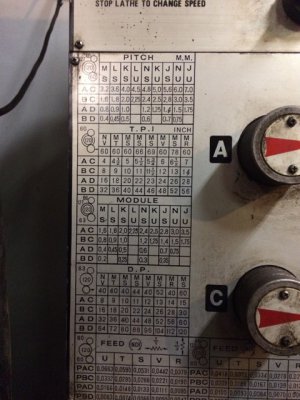

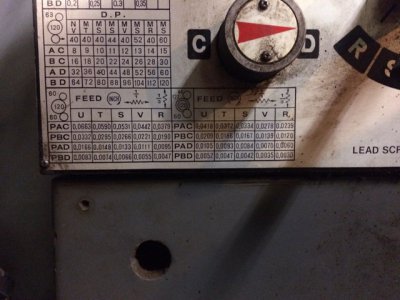

I'm having trouble finding any information about it, in particular a manual, so I can figure out what all the levers are supposed to do. Googling comes up with a couple of old machines, but nothing at all about this model, let alone manuals.

I'm also considering buying a King PDM30 milling/drilling machine to go with it (on sale right now for $1800 cdn), what models around that price should I consider?

I'm having trouble finding any information about it, in particular a manual, so I can figure out what all the levers are supposed to do. Googling comes up with a couple of old machines, but nothing at all about this model, let alone manuals.

I'm also considering buying a King PDM30 milling/drilling machine to go with it (on sale right now for $1800 cdn), what models around that price should I consider?

Steve Shannon, P.E.

Steve Shannon, P.E.