- Joined

- Mar 23, 2015

- Messages

- 21

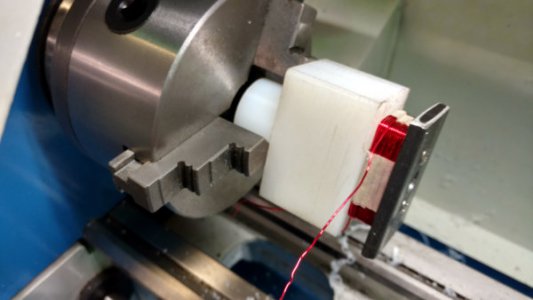

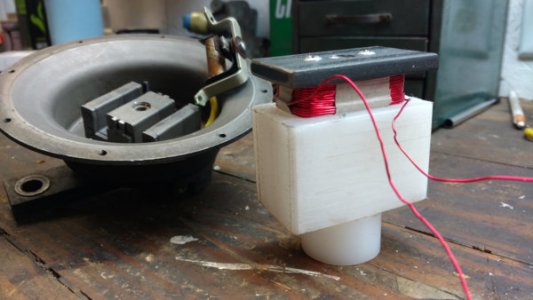

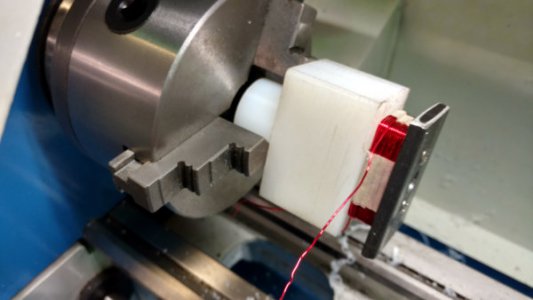

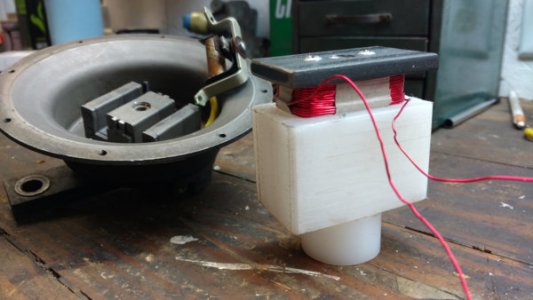

I had a vintage horn to restore from a 1959 Mercedes 190SL. The coil inside that energizes the electromagnet had burned out and shorted. It needed a new induction coil. All that's needed to build one is some enamel coated 21 AWG copper wire and something to wind it on. I decided to make a die out of some Delrin I had in the shop and here's the result. It works quite well. I just chuck it up in the lathe, turn the chuck by hand and wind the same number of turns of wire onto it. 84 in all! The one pictured was just a test winding of only 34 turns. Placing some masking tape on the die first insures that the whole thing will stay together by wrapping it around the coil before removal.

The pictures explain it. It was a fun project using my mill and lathe.

The pictures explain it. It was a fun project using my mill and lathe.