I wanted a quick to install and set up indexer for those jobs that do not justify the time required to installing the rotary table and aligning the vise. The original idea called for the lathe’s 3 or 4 jaw chuck, but it would not leave me much room on my mill. So I had to settle for this chuck which, after some work, is accurate enough, plus it can also double as a faceplate.

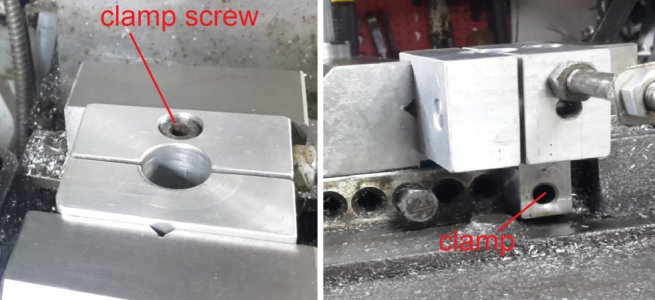

The tool consists of two aluminium blocks held together by guide pins. The blocks clamp around the chuck’s spindle when the vise is tightened. One of the blocks is held securely to the vise body to prevent the assembly from moving when the vise is loosened to index chuck.

Here it is in action machining a die.

The tool consists of two aluminium blocks held together by guide pins. The blocks clamp around the chuck’s spindle when the vise is tightened. One of the blocks is held securely to the vise body to prevent the assembly from moving when the vise is loosened to index chuck.

Here it is in action machining a die.