- Joined

- Jul 17, 2017

- Messages

- 71

I do not know anything about this machine other than what I can glean from looking at it. I can find no data or manuals on the net.

I am trying to decide whether this is strip for parts for projects this coming winter, or if it is worthy of restoring and upgrading to modern control system. The old control system is still intact, but the computer/cnc part is a separate cabinet and screen.

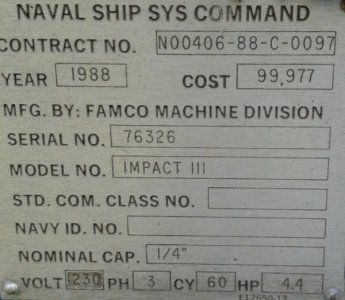

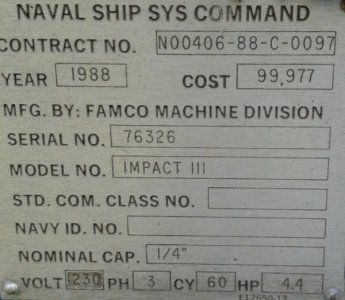

Built in 1988 by (or for) FAMCO, called an Impact III.

Double spindle, each spindle has separate servo motors for raise/lower.

Same size servo motors drive the table.

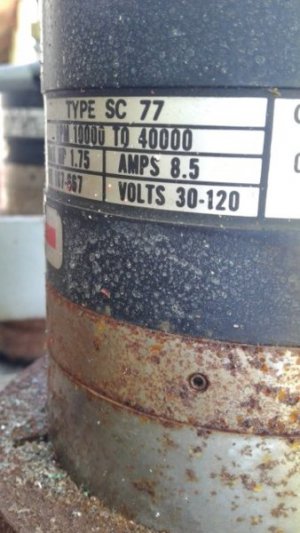

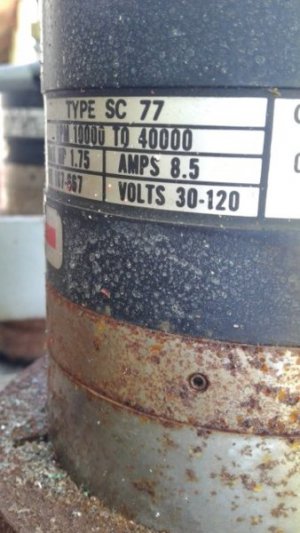

The spindle motors are up to 40,000 rpm and have a coolant system.

It looks to have been used to engrave signage and machine labels/tags. The labels/tags are the two layer plastic type.

The tool holder is brand new to me...

The data plate:

It says that it is 3 phase- it is not. The cabinet that came with it had a 3 phase plug, and inside the cabinet it was only 2 legs used. The red leg from the power plug was folded back and taped to itself inside the disconnect switch. The power conduit to the machine only had black, white and green.

The shroud that covers the two spindles and their up/down servo motors.

One of the two spindle motors... Precise Type SC77.

Here is a youtube video - the only thing I can find on the spindle motor so far:

The control panel. Normally the shroud surrounds this.

This was stored in an unheated but covered location for at least a year. I have not tried to power it up... Yet.

The daughter took a stab at figuring this thing out. Here she points to the relay board. She probably has this thing all figured out, but 3 year old speech is tough for me, unless it is "CARRY", "Banana!" or "NO!"

Note the sloth. He probably knows how this works too.

Note the sloth. He probably knows how this works too.

Coolant system. (This is separate from the coolant system for the spindle motors, which is a stand-alone system.)

Up/down Servo motors, x2.

Table servo motors, x2

The general layout - This is after removing the upper 2 shrouds.

If it is a strip-for-parts project then I can do that now. If it is worthy of getting it up and running, that would have to wait for a few months.

Any suggestions, brethren of the iron?

I am trying to decide whether this is strip for parts for projects this coming winter, or if it is worthy of restoring and upgrading to modern control system. The old control system is still intact, but the computer/cnc part is a separate cabinet and screen.

Built in 1988 by (or for) FAMCO, called an Impact III.

Double spindle, each spindle has separate servo motors for raise/lower.

Same size servo motors drive the table.

The spindle motors are up to 40,000 rpm and have a coolant system.

It looks to have been used to engrave signage and machine labels/tags. The labels/tags are the two layer plastic type.

The tool holder is brand new to me...

The data plate:

It says that it is 3 phase- it is not. The cabinet that came with it had a 3 phase plug, and inside the cabinet it was only 2 legs used. The red leg from the power plug was folded back and taped to itself inside the disconnect switch. The power conduit to the machine only had black, white and green.

The shroud that covers the two spindles and their up/down servo motors.

One of the two spindle motors... Precise Type SC77.

Here is a youtube video - the only thing I can find on the spindle motor so far:

This was stored in an unheated but covered location for at least a year. I have not tried to power it up... Yet.

The daughter took a stab at figuring this thing out. Here she points to the relay board. She probably has this thing all figured out, but 3 year old speech is tough for me, unless it is "CARRY", "Banana!" or "NO!"

Note the sloth. He probably knows how this works too.

Note the sloth. He probably knows how this works too.Coolant system. (This is separate from the coolant system for the spindle motors, which is a stand-alone system.)

Up/down Servo motors, x2.

Table servo motors, x2

The general layout - This is after removing the upper 2 shrouds.

If it is a strip-for-parts project then I can do that now. If it is worthy of getting it up and running, that would have to wait for a few months.

Any suggestions, brethren of the iron?