- Joined

- Jun 17, 2011

- Messages

- 2,062

Harvey,

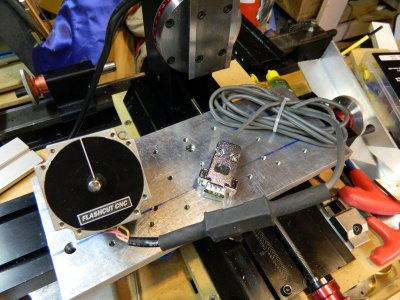

I took a quick look at the Arduino pages. Unlike the hardware we are using for our CNC projects, this stuff is intended as a starting point for robotics and anything you would use steppers for. Looks like a lot of fun in itself. From what I've seen, it would be possible to up-size the outputs from the Arduino board to control almost any size stepper, with the appropriate power supply.

If you need some hands-on help, I'm sure we could put our heads together and get things happening. I took a look around after you posted the question on the stepper with one coil open. I know I have a small motor around here somewhere, but it's hiding. It would likely work with your board.

I took a quick look at the Arduino pages. Unlike the hardware we are using for our CNC projects, this stuff is intended as a starting point for robotics and anything you would use steppers for. Looks like a lot of fun in itself. From what I've seen, it would be possible to up-size the outputs from the Arduino board to control almost any size stepper, with the appropriate power supply.

If you need some hands-on help, I'm sure we could put our heads together and get things happening. I took a look around after you posted the question on the stepper with one coil open. I know I have a small motor around here somewhere, but it's hiding. It would likely work with your board.