- Joined

- Nov 10, 2013

- Messages

- 837

The ancient Sony DRO on one of my Bridgeports (42") died quietly sometime after Christmas. It had lived a long life. It was so old that it used glowing wires for the numbers.

I started looking around at DRO prices on Ebay and various sites but am a little hesitant to dump another $500 + into the mill right now, especially since I haven't been making anything for sale for a long time. My smaller Bridgeport has a nice Chinese DRO with glass scales and is my go-to machine for everything that will fit so the larger machine usually has the table loaded with a vice, rotary table and dividing head for small projects so I don't have to set them up special for a project.

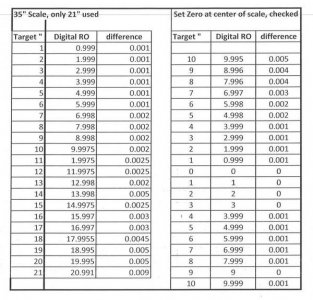

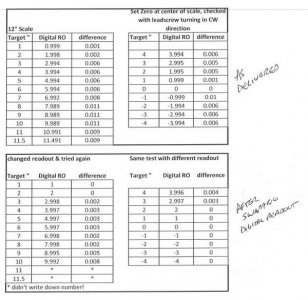

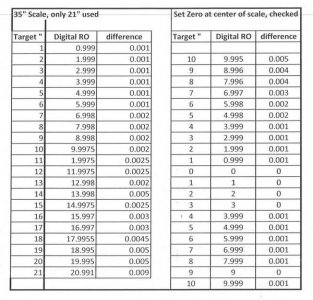

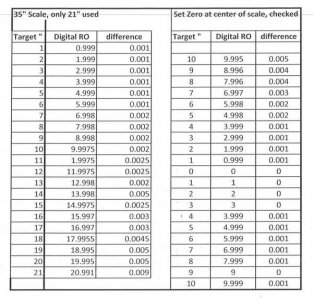

I've been wanting to see if the Igageing scales were any good so I got on Ebay and ordered a 35" and two 12" scales for roughly $120. I mounted the 35" on the X axis (table) which actually only uses 21" of the scale but it fits nice. Today I mounted a 12" to the Y axis, and soon will be mounting the other 12" to the knee (Z axis). I already have a 6" caliper style readout on the quill.

I have two concerns already with the scales I mounted, my first concern is batteries. The batteries in the 12" scale were dead already after having spent 48 hours in the readout with the power off. My other concern is accuracy.

With the Sony DRO mounted the readout numbers matched the dials on the handles whenever I took the time to set them. I verified the calibration of the scales with gauge blocks when I initially set the machine up and was confident that everything was right. Today before I closed up I checked the Igageing scales against the handwheels and was not impressed.

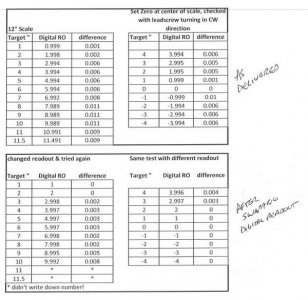

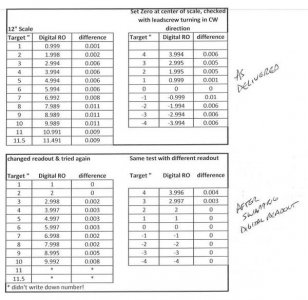

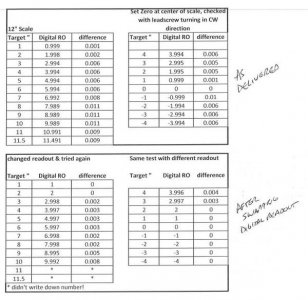

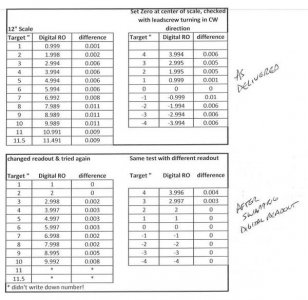

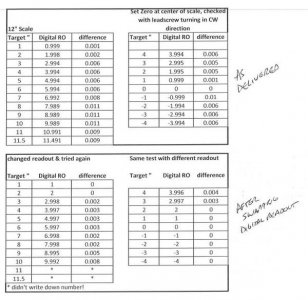

I checked the 12" scale first, "as delivered" with a brand new set of batteries (second set in two days). The chart on the top is as delivered. First I checked every inch starting from one end of the scale to the other, then I set zero roughly in the middle of the scale and went 4" each way, always taking the backlash out of the leadscrew and approaching the number on the handwheel turning clockwise. I didn't like what I saw so for S&G's I swapped the readouts from the 35" & 12" scale and tested it again (bottom chart):

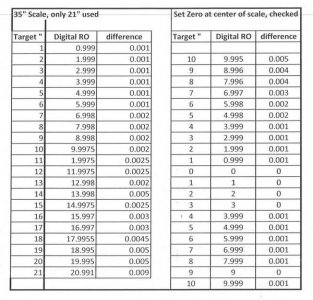

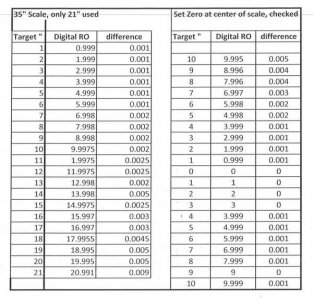

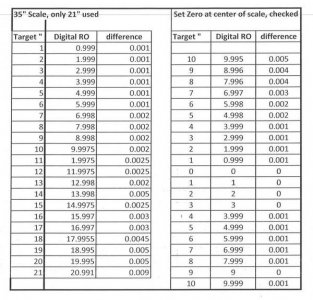

I was running short of time but I managed to do the same test on the X axis (still had the readout from the 12" on it):

So far I'm not impressed. I considered putting a set on my lathe but frankly I get better accuracy out of it's 62 year old dials than I could expect from these scales. At best, they will keep track of the inches traveled and I'll have to go back to using the handwheels for anything important.

I started looking around at DRO prices on Ebay and various sites but am a little hesitant to dump another $500 + into the mill right now, especially since I haven't been making anything for sale for a long time. My smaller Bridgeport has a nice Chinese DRO with glass scales and is my go-to machine for everything that will fit so the larger machine usually has the table loaded with a vice, rotary table and dividing head for small projects so I don't have to set them up special for a project.

I've been wanting to see if the Igageing scales were any good so I got on Ebay and ordered a 35" and two 12" scales for roughly $120. I mounted the 35" on the X axis (table) which actually only uses 21" of the scale but it fits nice. Today I mounted a 12" to the Y axis, and soon will be mounting the other 12" to the knee (Z axis). I already have a 6" caliper style readout on the quill.

I have two concerns already with the scales I mounted, my first concern is batteries. The batteries in the 12" scale were dead already after having spent 48 hours in the readout with the power off. My other concern is accuracy.

With the Sony DRO mounted the readout numbers matched the dials on the handles whenever I took the time to set them. I verified the calibration of the scales with gauge blocks when I initially set the machine up and was confident that everything was right. Today before I closed up I checked the Igageing scales against the handwheels and was not impressed.

I checked the 12" scale first, "as delivered" with a brand new set of batteries (second set in two days). The chart on the top is as delivered. First I checked every inch starting from one end of the scale to the other, then I set zero roughly in the middle of the scale and went 4" each way, always taking the backlash out of the leadscrew and approaching the number on the handwheel turning clockwise. I didn't like what I saw so for S&G's I swapped the readouts from the 35" & 12" scale and tested it again (bottom chart):

I was running short of time but I managed to do the same test on the X axis (still had the readout from the 12" on it):

So far I'm not impressed. I considered putting a set on my lathe but frankly I get better accuracy out of it's 62 year old dials than I could expect from these scales. At best, they will keep track of the inches traveled and I'll have to go back to using the handwheels for anything important.