- Joined

- Sep 2, 2013

- Messages

- 218

One of my jobs in the first shop I worked in was cutting stock. Even the larger saws have that problem. I usually used the short stubby off-fall as a spacer.

^^^ THIS ^^^

One of my jobs in the first shop I worked in was cutting stock. Even the larger saws have that problem. I usually used the short stubby off-fall as a spacer.

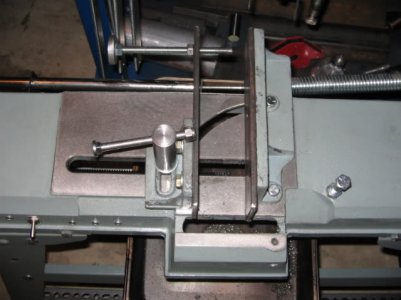

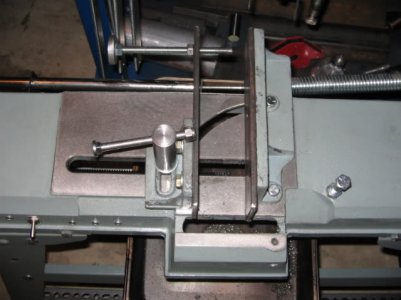

I hate the vice clamp on my 4x6 bandsaw.

I can't cut small pieces on it because of the floppy moveable jaw. I also think that the stationary, protractor jaw should be closer to the blade. Also that stationary jaw should be pushed back further to be able to use the maximum width of the blade opening, right close to the guide rollers. Plus, the clamping surface edge should be closer to the blade. Has anyone here tackled this problem? I don't want to reinvent the wheel, if someone else has already come up with a solution to this issue. I'm seriously thinking about making a whole new set of clamping surfaces for this piece of crap engineering debacle. Anyone?

Marcel

You see all the room there is to the right of the fixed jaw? I know that it's there for when we need to angle it, but sometimes that extra width would be helpful when cutting some wider stuff. That's not the biggest issue, but what the hell, while I'm at it, myswell !

Reminds me of a cutting fixture I made when I was rebuilding my corn head.I have a larger Startrite bandsaw and we all have the same problem. I have 2 solutions for cutting short or irregular pieces. When cutting pieces like you show in the picture I use the step blocks from my hold down set on the other end of the jaws. If it is larger piece I use 2 threaded rod from my hold down set with a coupling nut between them to adjust the back of the jaws just a little wider than the blade side.

Another handy accessory is a 4 x 6" plate of 1/2 " steel with several 1/2" holes in it for the bolts of hold down clamps. This allows me to clamp down almost any small or irregular sized pieces.

Hope this helps,

Michael

I have a larger Startrite bandsaw and we all have the same problem. I have 2 solutions for cutting short or irregular pieces. When cutting pieces like you show in the picture I use the step blocks from my hold down set on the other end of the jaws. If it is larger piece I use 2 threaded rod from my hold down set with a coupling nut between them to adjust the back of the jaws just a little wider than the blade side.

Another handy accessory is a 4 x 6" plate of 1/2 " steel with several 1/2" holes in it for the bolts of hold down clamps. This allows me to clamp down almost any small or irregular sized pieces.

Hope this helps,

Michael