- Joined

- Feb 2, 2013

- Messages

- 3,625

i Purchased a 3 axis IGaging EZ-View DRO kit,

it had a 24", 12" and 6" scales in the kit.

for my mill , it was going to be challenging to install the Y & Z axes without modifications

the X was relatively straightforward, but i decided to put it on the rear of the table- a little complication.

it just fit!

the Y an X are shown from the rear

the Y from the front

i needed to make a custom length stand off and drill a 1/4"-20 tpi stud into the knee casting

i messed up and drilled a hole into the main frame before realizing my mistake.

i recovered and drilled the standoff into the knee to travel with its motion

it looked sooo good in my head

i mounted the X and Y displays and checked function !

the system worked so far!

here is the video!

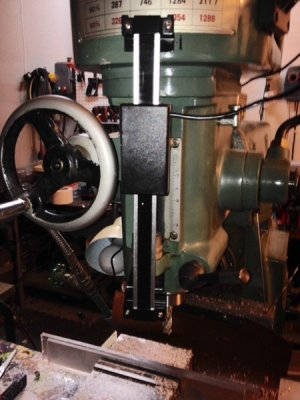

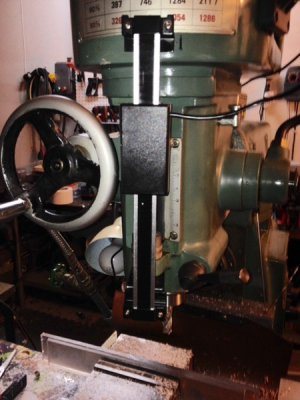

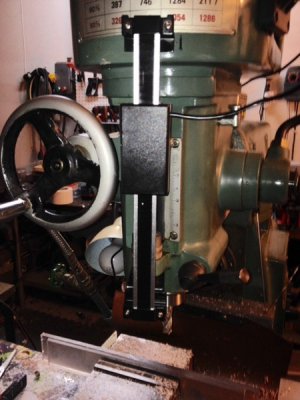

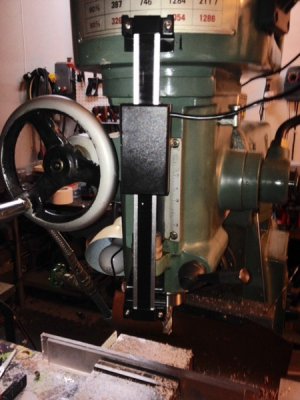

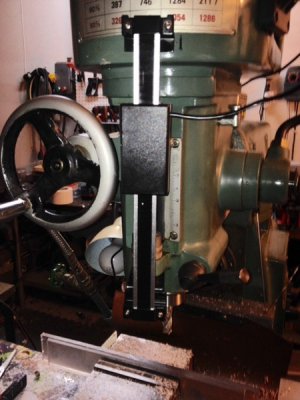

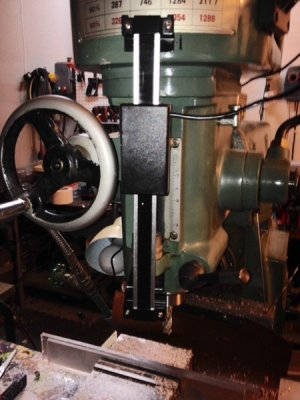

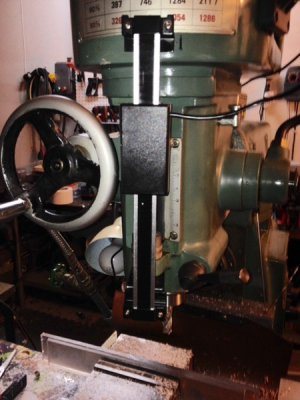

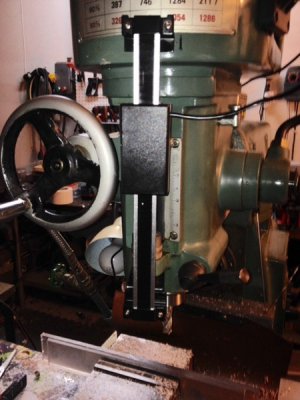

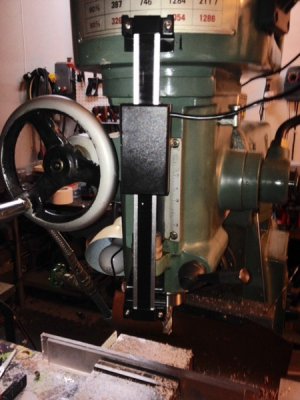

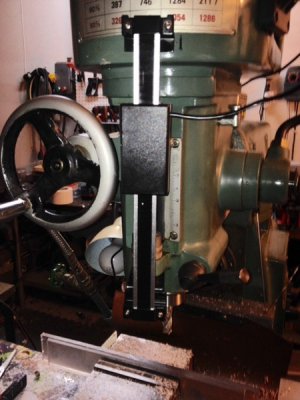

now the tricky part: axis ZED

i contemplated modifying a small electronic claiper to use for the Z, then the gears in my head started turning.

the next thing i know i'm modifying parts from their installation kit to make it happen!

i drilled the upper housing and worked out the spacing for the lower half

i had to slightly cant the dro scale to avoid the quill downfeed wheel, but not interfere with the quill stop

it was kind of a PITA to do the Z, a lot of figuring, filing, spacing, & general tomfoolery before it worked without interfereing with the original operation of the quill stop and the quill depth stop

and then it was a simple to install the display on the stack.

and i gave the system a test!

operation OK!

in the next segment, installing the dc converters to power the dro's without batteries!

thanks for looking and watching

it had a 24", 12" and 6" scales in the kit.

for my mill , it was going to be challenging to install the Y & Z axes without modifications

the X was relatively straightforward, but i decided to put it on the rear of the table- a little complication.

it just fit!

the Y an X are shown from the rear

the Y from the front

i needed to make a custom length stand off and drill a 1/4"-20 tpi stud into the knee casting

i messed up and drilled a hole into the main frame before realizing my mistake.

i recovered and drilled the standoff into the knee to travel with its motion

it looked sooo good in my head

i mounted the X and Y displays and checked function !

the system worked so far!

here is the video!

now the tricky part: axis ZED

i contemplated modifying a small electronic claiper to use for the Z, then the gears in my head started turning.

the next thing i know i'm modifying parts from their installation kit to make it happen!

i drilled the upper housing and worked out the spacing for the lower half

i had to slightly cant the dro scale to avoid the quill downfeed wheel, but not interfere with the quill stop

it was kind of a PITA to do the Z, a lot of figuring, filing, spacing, & general tomfoolery before it worked without interfereing with the original operation of the quill stop and the quill depth stop

and then it was a simple to install the display on the stack.

and i gave the system a test!

operation OK!

in the next segment, installing the dc converters to power the dro's without batteries!

thanks for looking and watching

Last edited: