- Joined

- Nov 21, 2012

- Messages

- 793

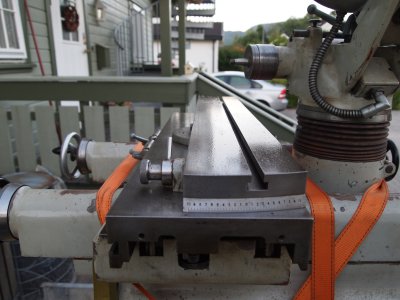

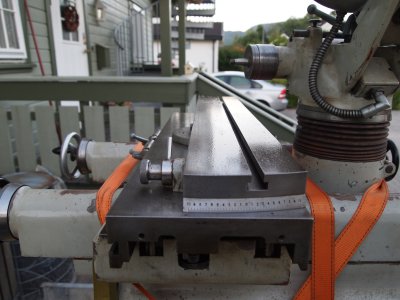

I have been wanting a tool grinder for a long time and had just missed out on one 6 years ago. I have always regretted this and have been searching for a grinder in my price range on a daily basis.

Having made contact with many people through owning a Colchester Chipmaster, I have had the pleasure in meeting Erik, aka rcflier on this forum. Erik lives in Denmark and I live in Norway and we have traded a few things in the past. About 10 days ago Erik contacted me regarding a Thörns grinder he had in his boiler room that he wanted to sell. Not wanting to pass this chance up, I organized myself as quickly as possible and made plans to take my 4 and 7 year old kids (they are on holidays and I had no baby sitter for them). Erik and I agreed to meet in Ystad, Sweden which is a 1370 km round trip.

Erik had booked a ferry trip from Denmark to Sweden, and I started the trek to Sweden. I arrived at about 21:00 with my tired kids in tow and met Erik at McDonalds. He had loaded the machine into a horse trailer and we were left with the challenge to load it into my little trailer. We were fortunate that we had assembled exactly the right equipment between us and that a kind tow truck driver happily assisted us in the transfer.

My trailer floor began to sag under the wait and I was forced to chock it up and leave it at a service station overnight. I arrived the next morning and headed to the hardware store with the trailer - gingerly driving the car so as not to disturb the machine and send it through the floor of my trailer. When arriving at the hardware store the warehouse guys happily assisted and lifted the machine off. They cut a piece of 22mm ply to reinforce the floor and then reloaded the machine. I strapped it down and was on my way.

The return trip took me over 12 hours but we made it. I still have the machine on the trailer as a friend with a crane truck is still on holidays. Overall, I am very happy with the machine and although it was a little rusty and worn, Erik did me a great deal and I will begin restoring it to it's former glory. It was a top-shelf machine in it's day and I believe it is worth the effort as it is both a tool grinder and surface grinder. I was very fortunate that Erik managed to find some of the documentation and the original sales document for it.

Anyway, enjoy the pics:

View attachment 58021

View attachment 58021

Having made contact with many people through owning a Colchester Chipmaster, I have had the pleasure in meeting Erik, aka rcflier on this forum. Erik lives in Denmark and I live in Norway and we have traded a few things in the past. About 10 days ago Erik contacted me regarding a Thörns grinder he had in his boiler room that he wanted to sell. Not wanting to pass this chance up, I organized myself as quickly as possible and made plans to take my 4 and 7 year old kids (they are on holidays and I had no baby sitter for them). Erik and I agreed to meet in Ystad, Sweden which is a 1370 km round trip.

Erik had booked a ferry trip from Denmark to Sweden, and I started the trek to Sweden. I arrived at about 21:00 with my tired kids in tow and met Erik at McDonalds. He had loaded the machine into a horse trailer and we were left with the challenge to load it into my little trailer. We were fortunate that we had assembled exactly the right equipment between us and that a kind tow truck driver happily assisted us in the transfer.

My trailer floor began to sag under the wait and I was forced to chock it up and leave it at a service station overnight. I arrived the next morning and headed to the hardware store with the trailer - gingerly driving the car so as not to disturb the machine and send it through the floor of my trailer. When arriving at the hardware store the warehouse guys happily assisted and lifted the machine off. They cut a piece of 22mm ply to reinforce the floor and then reloaded the machine. I strapped it down and was on my way.

The return trip took me over 12 hours but we made it. I still have the machine on the trailer as a friend with a crane truck is still on holidays. Overall, I am very happy with the machine and although it was a little rusty and worn, Erik did me a great deal and I will begin restoring it to it's former glory. It was a top-shelf machine in it's day and I believe it is worth the effort as it is both a tool grinder and surface grinder. I was very fortunate that Erik managed to find some of the documentation and the original sales document for it.

Anyway, enjoy the pics:

View attachment 58021

View attachment 58021