-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I am very confused by a video posted on Youtube to adjust a single jaw on a 4 jaw chuck.

- Thread starter jbmauser

- Start date

- Joined

- Jul 10, 2013

- Messages

- 1,188

This looks like an "independent" 4 jaw chuck. Which means that he's wasting his time numbering the jaws. If one jaw is not working properly, then it seems to me that the keyway or the screw adjusting the jaw is out of kilter. I'm not saying that the jaw is not worn. But I would eliminate everything else before grinding. Something as simple as a piece of swarf or in this case a sliver of oak in the keyway could be the problem. Mark

A

Andre

Forum Guest

Register Today

Change of thought.

Last edited by a moderator:

- Joined

- Aug 28, 2014

- Messages

- 315

So he got the jaws ground perfectly.( he thinks)

He has another video on the tube where he shows how he "restored" the lathe.

Ways were worn so he covered them all with rulon tape.

I bet he didnt grind/scrape the surfaces prior, so it will be crap and the lathe looks great but will work like a piece of .....

He has another video on the tube where he shows how he "restored" the lathe.

Ways were worn so he covered them all with rulon tape.

I bet he didnt grind/scrape the surfaces prior, so it will be crap and the lathe looks great but will work like a piece of .....

A

Andre

Forum Guest

Register Today

So he got the jaws ground perfectly.( he thinks)

He has another video on the tube where he shows how he "restored" the lathe.

Ways were worn so he covered them all with rulon tape.

I bet he didnt grind/scrape the surfaces prior, so it will be crap and the lathe looks great but will work like a piece of .....

I knew the ways looked red, but I thought it was a reflection of maybe a red packing blanket hanging from the ceiling or something for noise dampening.

Hmm....

- Joined

- Nov 27, 2012

- Messages

- 7,852

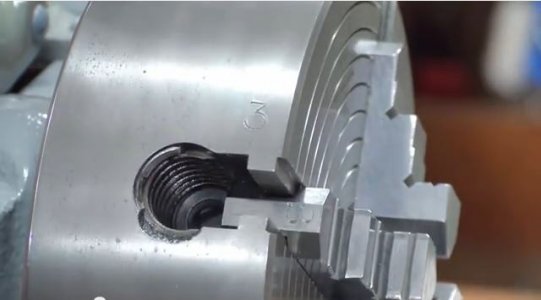

Since the key drive is so deep, looks to me like someone might have left the chuck key in there & turned on the spindle to cause that damage. If so, I wonder what the ways look like? And if so I bet they learned their lesson real quick!

- Joined

- Sep 11, 2014

- Messages

- 76

Having looked at the other videos in his channel I am getting a better understanding as to what is going on here. The videos are very well made, the lighting is uniform with background shadows that enhance the image but do not detract. The set is immaculately clean and organized with some items scattered to give the impression of use. You cant find a single chip or drop of oil on that work table. There are graphics to reinforce the narration and the narration is scripted, perfectly timed and overlayed. There are no images of the work being performed only of the finished results. I think the time & effort put into making the video is at least as much if not more than the work performed on the lathe.

I think the lathe is meant to be industrial art, a nice conversation piece. By his own admission he has not used the lathe, the "Franken-lathe" does not have a tool post. It looks to me that this is meant to be pretty and not necessarily functional. Clean the grit and grease, remove rust, polish, paint, replace worn wires and broken parts, clean and clear coat the plaques, cover worn ways with tape. I wonder if we are seeing product placement in the use of Rulon tape.

I think this is meant to be entertainment like "Tool Time" and not a mrpete222 instructional video.

Caster

I think the lathe is meant to be industrial art, a nice conversation piece. By his own admission he has not used the lathe, the "Franken-lathe" does not have a tool post. It looks to me that this is meant to be pretty and not necessarily functional. Clean the grit and grease, remove rust, polish, paint, replace worn wires and broken parts, clean and clear coat the plaques, cover worn ways with tape. I wonder if we are seeing product placement in the use of Rulon tape.

I think this is meant to be entertainment like "Tool Time" and not a mrpete222 instructional video.

Caster