Sounds like your main problem is that the pin is too hard. If I was designing an escalator, I'd use hardened pins. Best to keep to softer material until you have more experience with your lathe.

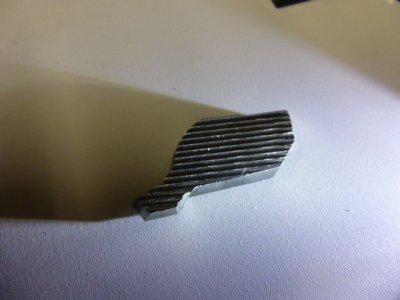

I've taken to keeping a small triangular file handy when I'm looking for stock (read in scrap). If the edge of the file easily cuts into the metal, it is soft enough to machine. If the file, which is very hard, won't cut into the piece, neither will HSS cutters. Carbide might, but then you need the rigidity mentioned above.

Charl is the first one I've noticed mentioning cutting speed. In the past, I've murdered a lot of cutters, both HSS and carbide, by not understanding about proper cutting speeds and feed rates, based on the material being cut.