- Joined

- Feb 7, 2015

- Messages

- 31

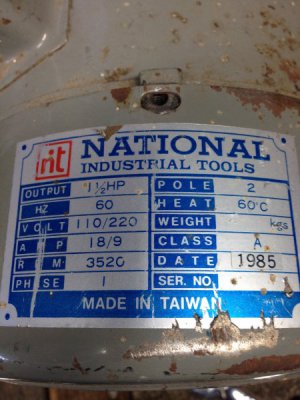

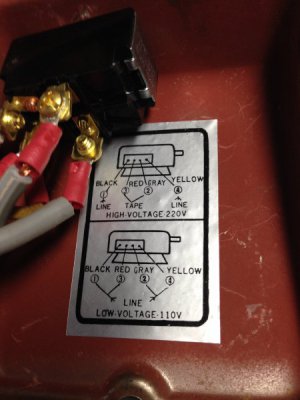

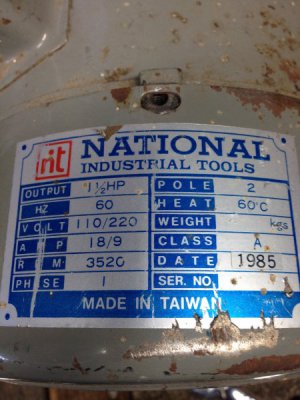

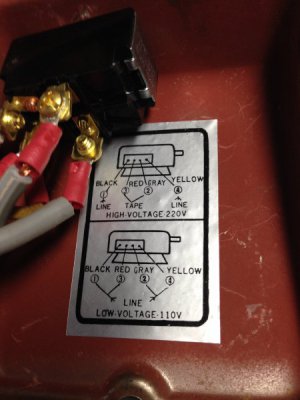

I have a 1 1/2hp capacitor start electric motor I'd like to run in reverse. I think it's off a table saw. It's now running a belt grinder. I'm consolidating space on the workbench and flipping the motor over I could gain 12 inches. The motor does not say it's reversible. It has 4 wires to connect to power but the wiring diagram shows that is for 110 or 220 volt running. I've been on u tube and really don't want to open it up and start cutting and splicing wires. So I'm thinking this is a non reversible motor and I should get a reversible one. What do you think?