T

TOOLMASTER

Forum Guest

Register Today

Having broke several on my bmx bikes yeeeeears ago headsets always worried me on motorcycles..it is one thing to fail at 20 mph but 120 is a different story

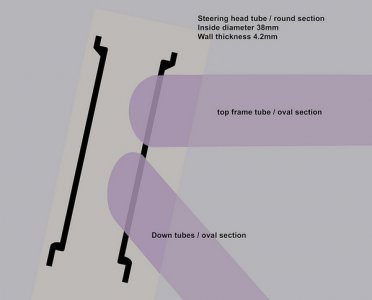

I would stronly consider turning up a reinforcing ring to fit around the OD, as thick as practical, depending on what type of cover fits over the bearing housing end of the head tube.