-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to Print on Metal

- Thread starter tjb

- Start date

I have no idea what 'brand' I use, but I'm into silk screening for much, much less - perhaps $100 (USD). I'm not sure how I started, but "Jacquard" is prominent on some of my supplies - you might start looking there.If you want something robust, you may want to think about subbing it out to a silk screening operation. Thermoset epoxy ink would wear well. More colors = more cost because each color requires its own mask and an additional print/bake step.

If you want to do it in-house, I found a 4-color silk-screening kit on ebay selling for $302. It includes an ink dryer, but maybe a toaster oven would work depending on the size of objects you want to print on. Or maybe a heat gun?

For multi-color printing you need a printing setup that provides good registration. And epoxy ink probably has a limited shelf life at room temp so some kind of refrigeration would save on ink cost. A cheap mini-fridge would be fine for that.

The exposure source to make the screens will be nearly as expensive as the printing hardware, but for experimentation purposes you could use sunlight. Exposure masks can be made with ink jet or laser printers with the right transparency material. An alternative would be to find someone who can make the screens for you. Your local t-shirt printing store might be able/willing to do that.

GsT

- Joined

- Feb 1, 2015

- Messages

- 9,623

Etched artwork is more robust than printed artwork. Etching is fairly simple to implement, either chemical etching or electrolysis etching. An etching mask is used and can be created by hand, by photographic process, or by mechanical process. Supplies for creating a mask with photoresist can be obtained from suppliers of printed circuit materials.

I used to make my own printed circuit boards using a dry film resist. The artwork was created on a transparency to form a photomask which was placed on top of the resist coated copper foil and exposed to light from a light box fluorescent lamps. The board was then developed to create the artwork and the board then etched in a chemical bath.

More recently, I had created the artwork as a CAD file and burned the pattern in a coating of nail polish on my target object.

the pattern was then etched using electrolysis. https://www.hobby-machinist.com/threads/etching-steel-using-a-2-5-watt-diode-laser.76262/

Once the artwork is etched, the pattern can be back filled with the paint of your choice. Since it is below the surface of the part, it is resistant to any abrasive wear.

I used to make my own printed circuit boards using a dry film resist. The artwork was created on a transparency to form a photomask which was placed on top of the resist coated copper foil and exposed to light from a light box fluorescent lamps. The board was then developed to create the artwork and the board then etched in a chemical bath.

More recently, I had created the artwork as a CAD file and burned the pattern in a coating of nail polish on my target object.

the pattern was then etched using electrolysis. https://www.hobby-machinist.com/threads/etching-steel-using-a-2-5-watt-diode-laser.76262/

Once the artwork is etched, the pattern can be back filled with the paint of your choice. Since it is below the surface of the part, it is resistant to any abrasive wear.

- Joined

- May 3, 2017

- Messages

- 1,997

That sounds like exactly what I'm trying to produce. This is a one-off project, and the finished product will be rather small. Those conditions shouldn't make jobbing it out too expensive. (Hopefully.) Thanks for the education.If you want something robust, you may want to think about subbing it out to a silk screening operation. Thermoset epoxy ink would wear well. More colors = more cost because each color requires its own mask and an additional print/bake step.

If you want to do it in-house, I found a 4-color silk-screening kit on ebay selling for $302. It includes an ink dryer, but maybe a toaster oven would work depending on the size of objects you want to print on. Or maybe a heat gun?

For multi-color printing you need a printing setup that provides good registration. And epoxy ink probably has a limited shelf life at room temp so some kind of refrigeration would save on ink cost. A cheap mini-fridge would be fine for that.

The exposure source to make the screens will be nearly as expensive as the printing hardware, but for experimentation purposes you could use sunlight. Exposure masks can be made with ink jet or laser printers with the right transparency material. An alternative would be to find someone who can make the screens for you. Your local t-shirt printing store might be able/willing to do that.

Regards

- Joined

- Apr 23, 2018

- Messages

- 6,559

- Joined

- Apr 23, 2018

- Messages

- 6,559

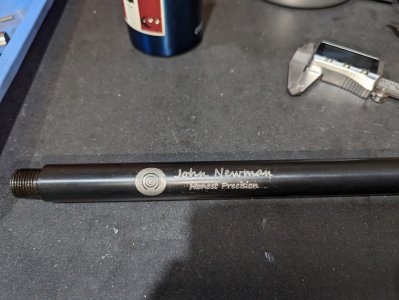

Those marks were done with a Luma Etch. I got mine for $40, new old stock. They still make them.Tangent from the OP, but kinda fits with the search title... What sort of marker do sharpening service shops use on saw blades and tool steel? I removed some surface rust from the tool below and was impressed to see it remained after heavy scrubbing with scotchbrite and brasso. Acetone didn't touch it either. Whatever it is, I want one.

View attachment 479823