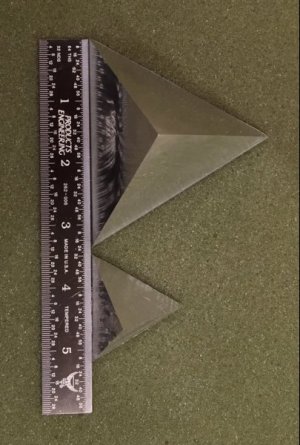

Having learned from the little tetrahedron, did it all again. But with a 4" cylinder rather than 2". It is really not intuitive that you have to turn 6 times as much metal into chips as the final tetrahedron. Lots of chip making.OK. Made a tetrahedron. (Well, a study piece really. Surface is ugly. And smaller than I would have liked.)

2" Round aluminum. Into my BS-0 dividing head on the mill. Angle up 19.47 degrees. (arcsin (1/3). Was fun to work that out). Mill a flat. Rotate 120 degrees. Do again. And again. Now have sharp point on the end of the round stock. To my surprise all pretty symmetric. Now need to cut off. Put on lathe. Cut off tool. Well, yeah it worked, but the surface finish of that 4th side is terrible. Note though, I am easily amused. the 1.7" a side tetrahedron is, indeed, on the mantle. Maybe next I mount with clay/glue or such and get a safe pass on that last side with the mill. I am more of a mechanical type so better machining through chemistry, while clearly smart, is not part of my intuition. I will note that the cylinder I started with was a big chunk of material. The tetrahedron waiting to come out was pretty small. I think the respective volumes are 4.44 and .61 in^3. I can't think of how to geometrically place a larger tetrahedron in a cylinder other than axially symmetric. And the real puzzle was the work holding challenge. Thanks list for the idea of starting with a cylinder. I am still puzzling too how to start with a cube and work hold a corner to be straight up. Mill that flat off. Repeat (ahh, but how hold?) for three more corners and get tetrahedron. Lose just 2/3 of the material, much less loss than cylinder.

-Bill

And, that 4th side. Yuck. Parting off was an ugly finish. I bandsawed the big one. Not much better. I have to try one of the chemical approaches--glue to bondo or something. Strong enough to face on the mill. And then find the magic (freezer? Heat gun?) And presto chango the metal pops free without surface damage. That will take some playing.

But the raw geometry of a tetrahedron is really interesting. While aware of the shape since a child, I don't think I have ever played with a big one. It is not what I had thought. It is actually much smaller than a cube. (Hard to explain what I mean by that). And very pointy. Dangerous points. Much more pointy than a cube. (And the point is straight up--not off to a side). The 6 edges are much sharper than the 12 edges of a cube (yes, I deburred them, but I did not round them)

"In theory there is no difference between theory and practice. In practice there is." A real tetrahedron is surprisingly different from a drawing of one or the thought of one.

-Bill