-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

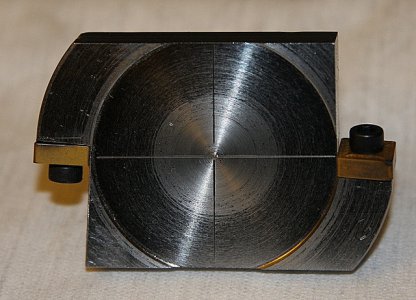

How have you made a flycutter for your mill?

- Thread starter HMF

- Start date

- Joined

- Nov 5, 2010

- Messages

- 871

DaveH, I really like that. I have a R8 blank that needs a purpose, and I also have a bunch of carbide bits with no toolholder.

What I need is a large swing flycutter for surface finish . Something like 4" diameter.

I may have to play with that a bit. Thanks for the inspiration

What I need is a large swing flycutter for surface finish . Something like 4" diameter.

I may have to play with that a bit. Thanks for the inspiration