- Joined

- Jul 20, 2014

- Messages

- 1,386

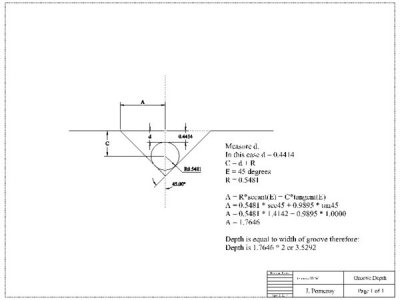

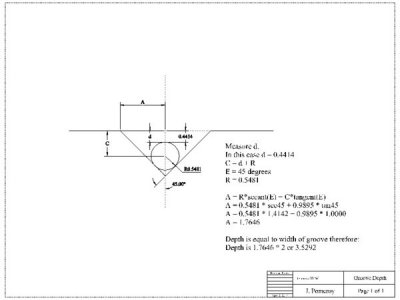

I'm working on my finger plates and need a way to accurately measure the size of the V shaped slot.

One will be .535" wide x .290" deep. I need to mill the V's to within a few thou on one FP design.

The other isn't so critical.

I watched a video by That Lazy Machinist using a depth mic with a

gage pin in a shop made V block he was milling. Not sure if his technique and he doesn't go in to details

of that measurement, so if anyone knows how to do this, please share. Thanks

One will be .535" wide x .290" deep. I need to mill the V's to within a few thou on one FP design.

The other isn't so critical.

I watched a video by That Lazy Machinist using a depth mic with a

gage pin in a shop made V block he was milling. Not sure if his technique and he doesn't go in to details

of that measurement, so if anyone knows how to do this, please share. Thanks