- Joined

- Sep 24, 2012

- Messages

- 484

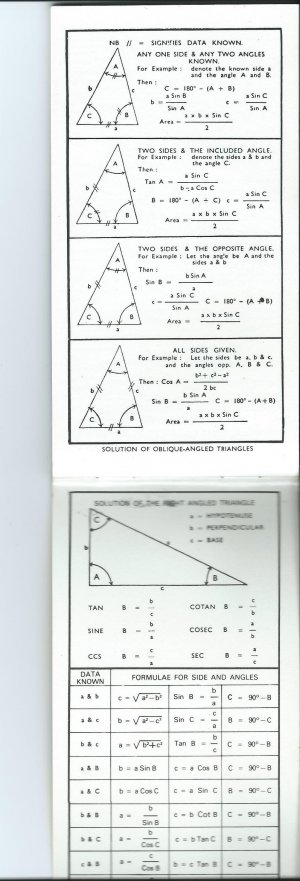

Glad the slope/taper problem had a happy ending and properous looking future! And by the way, that same formula is used for any slope problem such as for calculating the slope of a staircase, hill, mountain, wheelchair ramp... Just gotta watch out if you need the half-angle. For a wheelchair slope you are measuring the heights from a flat centerline so, just subtract the heights and divide by distance and hit arctan. No need to divide the answer by 2 in that case. Easy Spheasy...

When I press the reply button, I get 3 bars of editing options just above the editing window. On the 3rd row, there is X[SUB]2[/SUB] and X[SUP]2[/SUP] for subscript and superscript.

So... if you want to write Tan-1 just write it then, highlight just the "-1" and press the sub or super-script button. Now watch-out for something. You need to leave a space character after highlighting the "-1". If you don't everthing you type afterwared will show-up as scripted.

Ray

PS: I get the biggest kick out of your icon picture. There's another one like that with a kid sticking a screwdriver in a socket.

OK, I get it now!! I also read the subsequent posts about different kinds of angles...so now I know not 1 equation solves them all. It's nice to know how to use the TAN[SUP]-1[/SUP] button (hey look everybody...I can make superscripts!!)

Thanks for the comment re: my avatar...I chose it because for some reason I can't use an animated .gif file as an avatar. On my clock repair message board I belong to, I use THIS for an avatar....