Boring head! Use an edge finder to locate the edge of your part and move over to center the spindle on the edge of your part. Set the dial to zero and move the table away 0.4375" (7/16). Install the boring head and adjust the radius until the cutting edge just touches the work, lock it down and go! Incrementally move the table in as you make cuts until you reach the depth needed.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How can I make this feature?

- Thread starter DavidR8

- Start date

- Joined

- Feb 1, 2015

- Messages

- 9,625

Given the stated use, I would surmise that the critical dimensions are the hole diameters and their spacing. I also assume that you will be making a matched pair.

I would make the two holes first and mount the part to a sacrificial plate using the holes. I have a 7/8" end mill so I would use that for the arc. Barring that, I would use a boring bar.

Actually, I have a Tormach CNC so I would model it in CAD, create the G code in CAM and cut the profile on the CNC

I would make the two holes first and mount the part to a sacrificial plate using the holes. I have a 7/8" end mill so I would use that for the arc. Barring that, I would use a boring bar.

Actually, I have a Tormach CNC so I would model it in CAD, create the G code in CAM and cut the profile on the CNC

- Joined

- Jun 17, 2011

- Messages

- 2,062

I'd be inclined to use the annular cutter, but with a 1" piece of aluminum or hardwood clamped against the work in the vise jaws. With a slow feed, it should provide enough support. I really like using annular cutters. They give an amazing finish to the bore.

- Joined

- Mar 21, 2018

- Messages

- 1,599

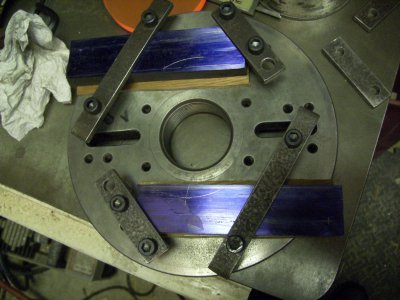

Mount it on a face plate and bore the recess. I had to do this when I made my knurler. Here are some pics of the setup:

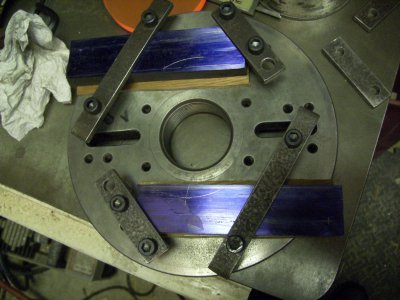

The orange disk is the diameter of the recess cut in the two parts. I mounted it in the tailstock just to align the two arms on the face plate. Once aligned, I simply bored the recesses.

The finished products:

The orange disk is the diameter of the recess cut in the two parts. I mounted it in the tailstock just to align the two arms on the face plate. Once aligned, I simply bored the recesses.

The finished products:

- Joined

- Oct 16, 2019

- Messages

- 6,585

Mount it on a face plate and bore the recess. I had to do this when I made my knurler. Here are some pics of the setup:

View attachment 452625

The orange disk is the diameter of the recess cut in the two parts. I mounted it in the tailstock just to align the two arms on the face plate. Once aligned, I simply bored the recesses.

View attachment 452626

Coincidentally I just bought a face plate yesterday

- Joined

- Mar 21, 2018

- Messages

- 1,599

Coincidentally I just bought a face plate yesterday

With the size of your lathe and the size of the part, this shouldn't be a problem. Is it just one arm, or are both like this? If only one, you might have to place something on the opposite side of the arm for balance.