- Joined

- Dec 30, 2012

- Messages

- 24

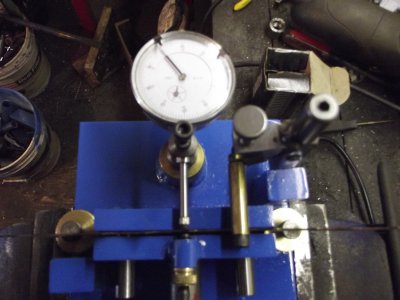

This has been done by many people, some are really done nice, some are pretty rustic looking, and some even make them to sell, me being cheap and needing one, it took two and half shop days from scratch, dial indicator 25 bucks, a couple pieces of scrap steel....

Not exactly any plan sets kicking around, mind you it isn't rocket science either, it is a single tooth setter, not a dual tooth setter, my thinking, what am I in a hurry for anyhow.

Next?

A blade sharpener.

Oh sorry about the size of the pic's, I'm working on making them a little bit less KB size.

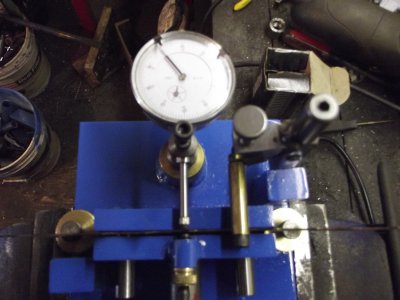

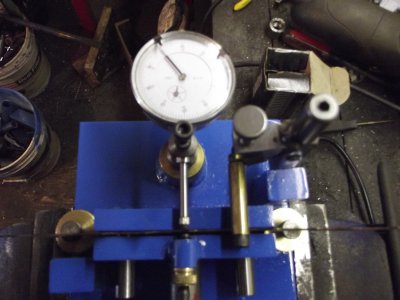

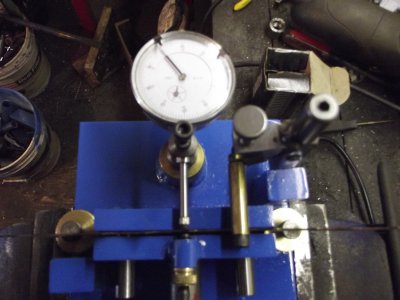

Okay, a little description about how it works, (there is a scrap piece of blade in the jaws) by moving the cam lever arm, that advances the push ram, which closes the jaws, there is an adjustable screw on the top of the jaws that does the bending, the dial indicator measures the set, there is also a moveable advancer, moveable meaning from one side of the setter to the other, since with a single tooth setter the blade will have to be turned inside out to do the set on the other teeth, there are also a band height adjustment, since sharpening can lower the gullet of the blade and tooth height.

I use bands with a 7/8 inch tooth spacing, so the blade advancer is also adjustable, just in case I decide to change to another tooth spacing in the future.

Not exactly any plan sets kicking around, mind you it isn't rocket science either, it is a single tooth setter, not a dual tooth setter, my thinking, what am I in a hurry for anyhow.

Next?

A blade sharpener.

Oh sorry about the size of the pic's, I'm working on making them a little bit less KB size.

Okay, a little description about how it works, (there is a scrap piece of blade in the jaws) by moving the cam lever arm, that advances the push ram, which closes the jaws, there is an adjustable screw on the top of the jaws that does the bending, the dial indicator measures the set, there is also a moveable advancer, moveable meaning from one side of the setter to the other, since with a single tooth setter the blade will have to be turned inside out to do the set on the other teeth, there are also a band height adjustment, since sharpening can lower the gullet of the blade and tooth height.

I use bands with a 7/8 inch tooth spacing, so the blade advancer is also adjustable, just in case I decide to change to another tooth spacing in the future.