- Joined

- Jan 20, 2017

- Messages

- 6

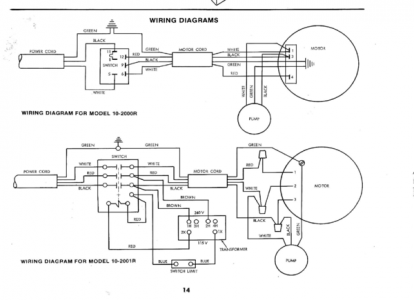

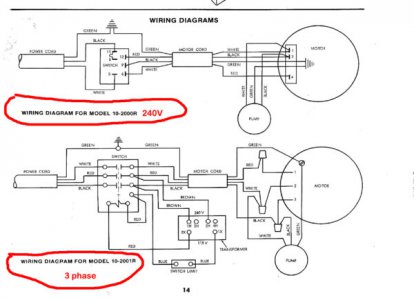

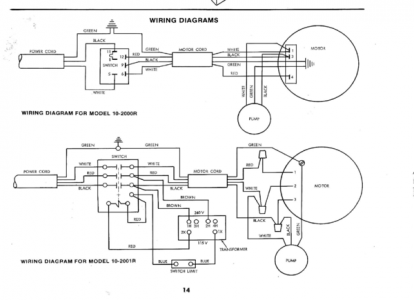

I just bought an Emerson Bandsaw off CL. It has a 3 phase motor and I'm going to switch it to a 120/240V motor. Emerson's 3 phase wiring diagram has me confused. I would have thought there would be 3 line wires, 1 neutral wire and a ground wire. There diagram show Black, Red, White & Green. With my limited electrical knowledge that seems weird. Like its 240V black & red are line, white is neutral & green is ground. What am I missing?

I want to try and use the original switches if possible. Any help would be appreciated.

Thanks,

Brandon

I want to try and use the original switches if possible. Any help would be appreciated.

Thanks,

Brandon