- Joined

- May 14, 2018

- Messages

- 335

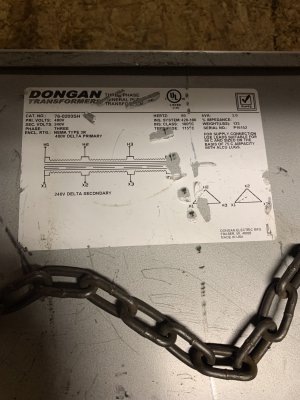

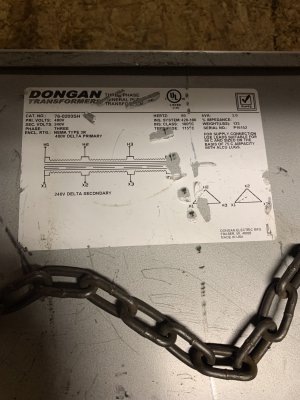

I have what I believe to be a 440v 3 phase motor that cannot be rewired for 230v. There is no data plate to consult. There are only three leads coming out of the motor, and the motor starter has a 440v coil. My questions-am I right this seems to be a strictly 440v motor? Any way to internally rewire? Any way to test if it is 230 or 440v? If I apply 230v to it(bypass the starter for now) to test it, will that damage it? I have a transformer that I could back feed to get 440v, so I could do that, but if it isn’t a 440v motor, will that damage it? Also, I think my transformer is a little too small. I believe the motor to be 5hp.