- Joined

- Feb 5, 2015

- Messages

- 662

You can't turn this part between centers as they are not on center as there is 4º included between the features being turned as far as I can tell from the limited part description. The turning is easy, the work holding is difficult.

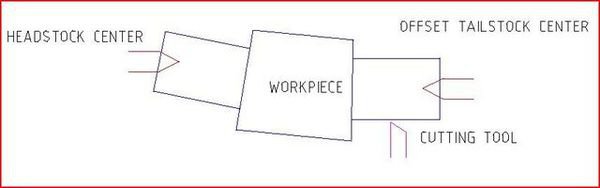

Where's the problem ? So far as I know offsetting the tailstock to produce work like this is as old as the invention of the metal-cutting/screw-cutting lathe -

This sketch is highly exaggerated dimensionally but I think that the concept is easily perceived.

Last edited: