- Joined

- Feb 6, 2015

- Messages

- 45

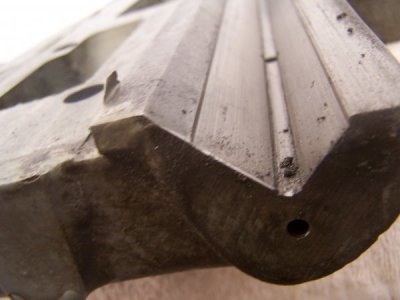

Hey guys, this lathe is up for sale as part of an estate. I know it would be a big step up from my Atlas TH-54 as long as it's not terribly worn out, but what I don't know is exactly what I'm looking at here. Based on the features I've seen comparing it to others on the internet I'm guessing either a 15" or 16" by about 6' bed. Does that seem correct? There appears to be a stray handle of some type on the tray above the gearbox, does that look like it's from this machine? Are there any pitfalls to look out for specific to these lathes? I know the basic things to look for on a used machine but I have no experience with South Bend products. And assuming I buy it, would a standard 1/2" drive socket set (up to 1"), combination wrench set (up to 1") and large screwdriver set be sufficient to break this down into major assemblies (headstock/bed/pedestal drive/legs) for transport or would I need any special tools? The pictures attached are all the information that's available until the day of the sale and at that point I want to have any info that I can get. Thanks.

-Drew

-Drew