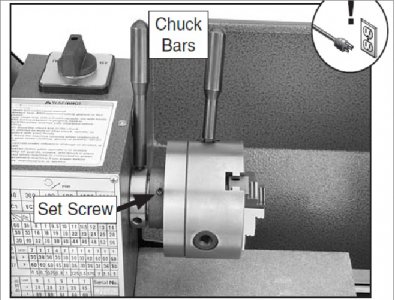

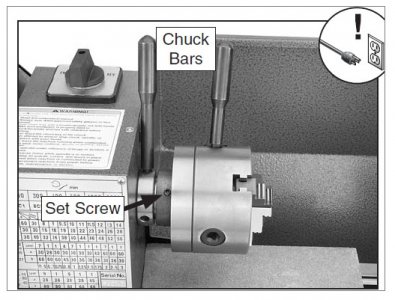

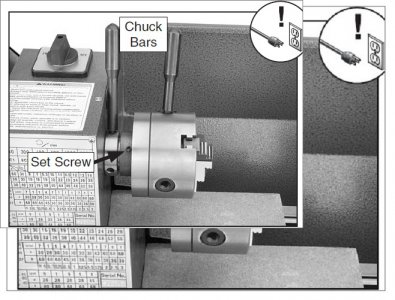

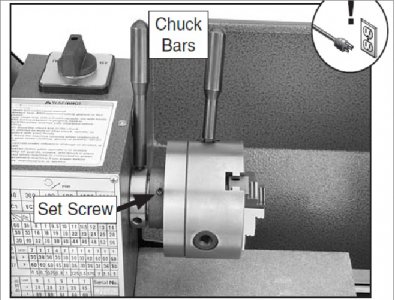

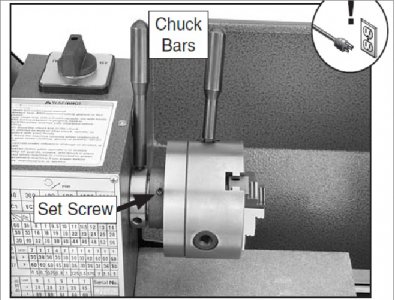

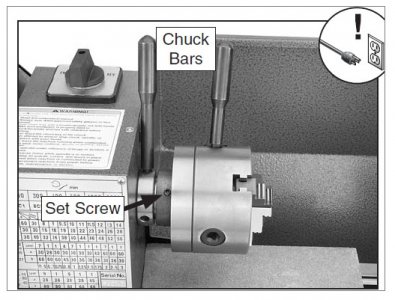

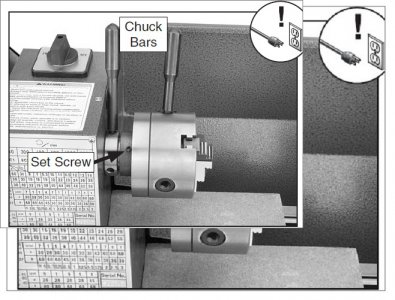

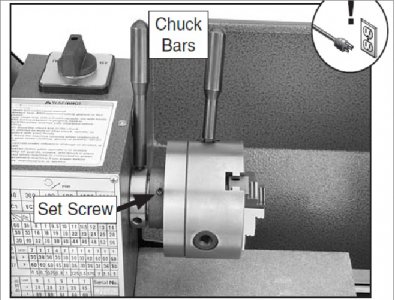

Hello! I'm having trouble getting the chuck off of my lathe. This lathe has been very lightly used since new about 2 years ago. The manual is a joke and doesn't provide any instructions for removing the chuck. I found the manual for the Grizzly g4000 lathe which is almost identical. According to the manual, two set screws need to be loosened before the chuck can be unscrewed. See photo below. My chuck has only one set screw. AND it is stripped. Actually, the setscrew seems to be made of very soft material. Is it possible that it never got hardened. I have tried several allen wrenches and they all spin, Any suggestions for getting this chuck off? Thanks, Frank