-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Height gage help

- Thread starter Joe P.

- Start date

- Joined

- Jan 16, 2017

- Messages

- 216

Did you reset the counter, have a pic of what you mean?

- Joined

- Sep 27, 2014

- Messages

- 3,123

Red x s , search posting pics on tapatalk so pics work

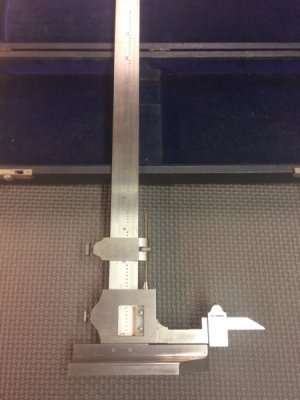

I just picked up a Brown & Sharpe vernier height gage. How do I make measurements that are less 1.040" since the gage is bottomed out

Sent from my iPhone using Tapatalk

- Joined

- Jan 16, 2017

- Messages

- 216

Correct me if I'm wrong, but shouldn't the caliper be flat, so it touches the bottom of your table. Like these ones are the ones we have in class.

My best guess is....the measuring face you have should be lowered on the extension. It looks like the post holding it is upside down too? I'm sure others more knowledgeable will be able to help.

My best guess is....the measuring face you have should be lowered on the extension. It looks like the post holding it is upside down too? I'm sure others more knowledgeable will be able to help.

- Joined

- Sep 2, 2013

- Messages

- 54

That's what I thought, but with the gage bottomed out all the way it reads 1.040" and with scriber the way it is picture that is the true height. With the scriber mounted below the arm the actual height is .375"

It just seems like an odd dimension to add 1.040" under the work in order to zero the gage, unless I am looking at this from the wrong perspective.

Sent from my iPhone using Tapatalk

- Joined

- Dec 27, 2014

- Messages

- 4,055

I believe you need what is called in the above illustration, a "Probe Extension." That would bring the contact point down to the surface plate. Perhaps you can make an adjustment on the vernier scale to zero it out by loosening the two slotted screws.

Edit, correct typo

Edit, correct typo

Most of the height gauges I've looked at on Flea Bay are all similar....And yet the accessories are not interchangeable. The offset of one model Brown and Sharpe may connect to a Starrett gauge...But it will not function as designed.

It looks like that one does not have the proper offset for said Vernier Height gauge. I've also seen quite a few gauges for sale which were missing all of the accessories. That's common since the sellers are usually people who are clueless about machinist gauges and devices.

It looks like that one does not have the proper offset for said Vernier Height gauge. I've also seen quite a few gauges for sale which were missing all of the accessories. That's common since the sellers are usually people who are clueless about machinist gauges and devices.

- Joined

- Jul 2, 2014

- Messages

- 7,594

It is only meant to measure down to 1.000", note that the scale ends there. There are offset attachments that let it go down the other inch, though then you need to remember to subtract an inch. You can also use a 1-2-3 block or a gage block to take up the difference. I think you also have other problems with the setup as well. It should go down to 1.000", not 1.040". The sliding portion may not be correct for your stand (Frankengage.)

- Joined

- Jan 16, 2017

- Messages

- 216

Agree with Bob Korves....