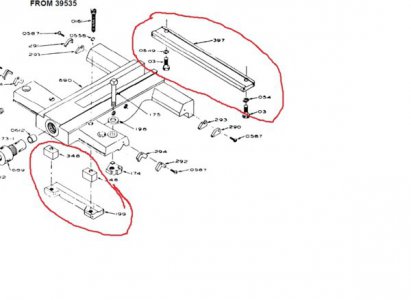

I am not certain the bar ever ran true, this is a new to me lathe. Before, I was learning to thread but I was using very short pieces of stock. These same pieces of stock now seem out of round. I did make certain to clean the spindle threads very well both inside and outside threads. I believe we are on to something with the method in which I am tightening the saddle to the ways, maybe something is missing?? I looked over the parts breakdown, and think I may have determined the proper tightening points but those are bottomed out and doing nothing. I will have to look deeper into it when I get back in town later this week. TO answer your questions:

I am turning down 1.25" mild steel rod (cold roll?)

The tool bits are both HSS and carbide

The speeds I have tried are 350-700 RPM my feed is set to .011? and the DOC has varried but .002 to .0010

I have tried several tools, made new ETC with no luck. I thought the same thing.

Thank you for the help,

Jason

I am turning down 1.25" mild steel rod (cold roll?)

The tool bits are both HSS and carbide

The speeds I have tried are 350-700 RPM my feed is set to .011? and the DOC has varried but .002 to .0010

I have tried several tools, made new ETC with no luck. I thought the same thing.

Thank you for the help,

Jason